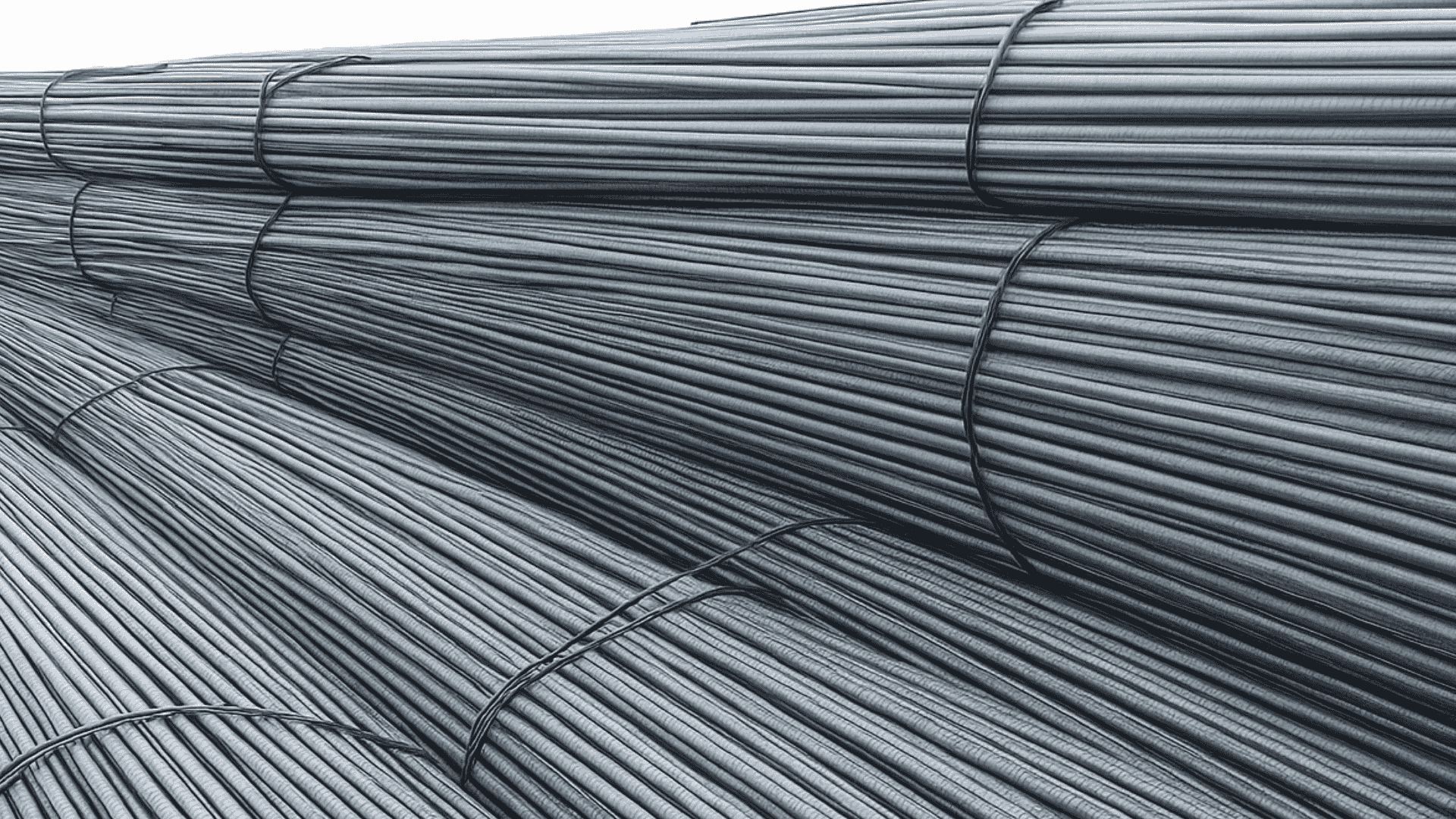

How Many Rods in an 8mm Bundle: Standard Counts Explained

Accurate rod counts in 8mm bundles form the basis for reliable reinforcement planning, since bundle size directly determines how much steel moves into cutting, bending, and cage assembly. A consistent count keeps BOQs aligned with actual supply and lowers the risk of mismatches between ordered and available tonnage on site.

Because 8mm rods are widely used in slabs, ties, and secondary reinforcement patterns, even small bundle variations affect daily production targets, bending schedules, and material allocation for each cycle. Unverified counts lead to uneven distribution across floors and disrupt reinforcement flow during critical stages.

Manufacturers follow different rolling tolerances, creating variations in weight per rod and in the number of pieces packed into each bundle. This blog explores how these variations occur, how bundle counts are calculated, and how predictable numbers support smoother planning, purchasing, and execution across reinforcement phases.

Key Takeaways

-

8mm bundles follow a predictable range of 10–12 rods, and this count drives every reinforcement calculation, from BOQs to bending schedules to daily material deployment on site.

-

Bundle size for all TMT diameters is weight-driven, not piece-driven, which is why 10mm, 12mm, 16mm, 20mm, 25mm, and 32mm rods each have their own fixed bundle ranges used across the industry.

-

Rod count can be calculated instantly using a single formula: Rod Count = Bundle Weight ÷ Weight of One Rod, allowing fast verification during receiving or cross-checking supplier claims.

-

Bundle variations happen because mills follow different rolling tolerances and metallurgical controls, making 8mm rods more sensitive to diameter shifts and changing final rod counts between brands.

How Many Steel Bars Are There in One Bundle

Bundle size depends entirely on the diameter of the TMT bar and the actual weight of each rod, since manufacturers pack bundles according to total bundle weight rather than a fixed number of pieces. Smaller diameters contain more rods per bundle, while larger diameters reduce the rod count because each bar carries significantly more mass. This size-to-weight relationship creates predictable ranges that engineers use while planning reinforcement quantities.

-

8mm bars: Typically 10 to 12 rods per bundle, since the lighter mass allows more pieces within the standard bundle weight range.

-

10mm bars: Usually 7 to 9 rods per bundle, as the increased diameter raises per-rod weight and reduces the total pieces that can be grouped.

-

12mm bars: Commonly 5 to 7 rods per bundle, offering a balanced combination of manageable weight and structural load-bearing performance.

-

16mm bars: Around 3 rods per bundle, due to a significant jump in unit weight and their use in heavier structural zones.

-

20mm bars: Typically 2 to 3 rods per bundle, designed for high-load applications where fewer, heavier bars are required per assembly.

-

25mm bars: Generally, 1 rod per bundle, as the bar's mass reaches levels where bundling multiple pieces becomes impractical for handling.

-

32mm bars: Also supplied as single-rod bundles because of their substantial weight and their role in large-scale, heavy-duty reinforcement.

The table below provides standard industry values used to estimate bundle quantities across commonly used TMT sizes.

| Diameter (mm) | Approx. Weight per Rod | Typical Rods per Bundle |

|---|---|---|

|

8 mm |

4.7 kg |

10 rods |

|

10 mm |

7.4 kg |

7 rods |

|

12 mm |

10.6 kg |

5 rods |

|

16 mm |

18.9 kg |

3 rods |

|

20 mm |

29.6 kg |

2 rods |

|

25 mm |

46.3 kg |

1 rod |

|

32 mm |

75.7 kg |

1 rod |

Related: How to Calculate TMT Bar Weight: A Simple Guide

How to Calculate Rod Count for Your Project

Rod count is derived from reversing the standard bundle-weight formula. Since bundle weight equals the weight of one rod multiplied by the number of rods, dividing the total bundle weight by the unit rod weight gives the exact count.

Formula: Rod Count = Weight of Bundle ÷ Weight of One Rod.

If an 8mm rod weighs 4.74 kg and the bundle weighs 50 kg, the calculation is 50 ÷ 4.74, giving approximately 10 to 11 rods. This provides a direct and dependable method for confirming quantities when bundles arrive without clear rod-count markings.

Why Different Brands Have Different Bundle Counts

Different manufacturers maintain their own rolling tolerances and weight benchmarks, which leads to noticeable variations in rod weight and final bundle composition. These variations are amplified in 8mm rods because their smaller diameter makes even minor deviations more influential on total mass. As a result, brands with tighter controls deliver steadier bundle counts, while others may show wider fluctuations across batches.

-

Variation in rolling tolerances: Each mill follows its own production settings within BIS or ASTM limits, and these micro-deviations in diameter directly change mass per meter across the full 12-meter length.

-

Differences in density and metallurgical consistency: Alloy composition, cooling rate, and finishing processes affect the true weight of each rod, creating measurable differences between mills that use different production lines.

-

Weight-based bundling practices: Bundles are assembled according to total weight rather than a fixed number of rods, so any shift in unit weight changes the rod count in each bundle.

-

Local mills vs. premium manufacturers: Premium brands maintain tighter dimensional control, resulting in more predictable rod weights, while smaller mills may show higher variability in both diameter and mass.

Role of 8mm Rods in Structural Work

8mm rods serve as a primary component in secondary reinforcement systems across slabs, beams, ties, and lightweight structural elements. Their smaller diameter allows tighter spacing and denser reinforcement layouts, making them essential in projects with repetitive floor cycles. Because of this adaptability, they support fast-paced construction environments that require consistent reinforcement supply.

-

Widely used in slabs, beams, and column ties: The diameter suits reinforcement zones that need closely spaced bars, enabling structural stability without adding excessive steel weight.

-

Preferred for high-volume bending and fabrication: Their size supports quick cutting, shaping, and tying, which helps fabrication yards maintain output even during peak production phases.

-

Easy handling across multi-storey work fronts: Lightweight rods move quickly through shuttered areas, allowing crews to position reinforcement efficiently during rapid slab and beam cycles.

-

Stable performance in dense reinforcement patterns: The smaller diameter ensures bars can fit into narrow reinforcement covers where larger sections would disrupt spacing or clash with design clearances.

-

Dimensional accuracy supports consistent reinforcement flow: Even slight diameter variations can alter bending precision and cage alignment, so correctly rolled 8mm rods help maintain smooth reinforcement placement across floors.

Also read: Planning Steel Purchase? Check 10 mm Rod Weight & Bars per Bundle.

Buying Checklist for 8mm Rod Bundles

8mm rod bundles must be checked thoroughly at the time of delivery to avoid mismatches between ordered and supplied quantities. Verifying bundle specifications helps maintain a steady reinforcement flow, since even small shortages can disrupt bending, tying, and slab-cycle sequencing. A structured inspection reduces delays and ensures that reinforcement work progresses in line with planned timelines.

Here is the essential checklist used during receiving and verification:

-

Verify declared bundle weight and rod count: Cross-check the bundle’s actual weight and the number of rods against purchase records to confirm consistency with the dispatched material.

-

Confirm rod length and physical uniformity: Standard 12-meter length must be validated, along with straightness and dimensional accuracy, to prevent bending or alignment issues during fabrication.

-

Inspect heat numbers and MTC compliance: Traceability documents help confirm grade, rolling details, and chemistry, ensuring every batch aligns with structural specifications.

-

Check tagging and supplier identification: Each bundle should carry clear labels with batch information, allowing proper segregation and sequencing for different reinforcement zones.

-

Validate SteelonCall’s quality screening: Deliveries pass through weight, dimension, and certification checks before dispatch, stabilizing bundle counts and improving consistency across all cycles.

Conclusion

Understanding how many rods come in an 8mm bundle allows reinforcement planning to run without interruptions, since accurate bundle sizing supports steady fabrication output and predictable material flow. With consistent weight references and verified bundle counts, projects maintain better control over scheduling, allocation, and daily reinforcement demand.

Standardized bundle ranges also simplify ordering and reduce discrepancies between theoretical quantities and onsite supply, especially for fast-moving structural cycles. When supported by reliable sourcing, consistent rod dimensions, and predictable bundle composition, it helps eliminate delays linked to shortages or mismatched steel deliveries.

As an online steel marketplace, SteelonCall connects projects directly with verified mills and suppliers that follow controlled rolling and weight benchmarks. This model brings clarity to bundle sizing, strengthens traceability, and ensures material is sourced from dependable networks rather than fragmented local channels.

For bulk TMT bundles, recurring reinforcement cycles, or long-duration project requirements, SteelonCall delivers accurate steel options supported by transparent data and smooth digital ordering.

FAQs

1. How many rods are typically in one 8mm bundle?

Most bundles contain 10-12 rods, depending on the manufacturer’s rolling tolerance and weight benchmarks.

2. How many 8mm rods make 1 quintal?

Since one 8mm rod weighs about 4.74 kg, approximately 21 rods make 1 quintal of steel.

3. Do bundle counts change with each manufacturer?

Yes, manufacturers follow different tolerances and production settings that influence rod weight and change bundle quantity.

4. Can I request custom bundle sizes?

Certain mills offer customized bundling for bulk orders, allowing purchasing teams to align rod counts with site handling preferences.

5. What is the tolerance allowed for 8mm TMT bars?

BIS standards allow slight variations in diameter and weight, but premium brands maintain tighter tolerances for better accuracy across bundles.