5 Best Roofing Materials for Coastal Homes in South India

Choosing the best roofing material for coastal homes isn't just another design decision. The environment here puts roofs under constant stress from salt‑laden air, high humidity, and strong winds.

Salt corrosion alone can accelerate material breakdown and reduce roof lifespan, while conventional shingles and untreated metal can become brittle, leak, or deteriorate much faster near the sea.

This blog highlights some most durable roofing options for coastal climates in South India. You'll learn which materials resist corrosion, withstand heavy weather, and deliver long‑term value so you can make confident choices that keep projects on schedule and minimise costly rework or maintenance.

Key Takeaways

-

Aluminium & coated Metals are best for coastal roofs due to their corrosion resistance against salt air.

-

Wind resistance is crucial; metal roofing with standing seams or clay tiles can withstand winds often rated up to 138 mph, specifically in coastal regions.

-

Clay & concrete tiles offer 50+ years of durability in coastal climates, ideal for long-term value.

-

Moisture management is vital for coastal areas like the Western Ghats, where rainfall averages 2,000–3,000mm, with local extremes up to 10,000mm.; choose non-porous materials.

-

Low-maintenance materials like stone-coated metal and synthetic composites reduce long-term upkeep costs.

Why Coastal Roofs Need Special Materials

Coastal environments subject roofing materials to a unique mix of stresses that typical inland conditions don't present. Salt‑laden air continuously accelerates material corrosion, while high humidity and frequent heavy rains add moisture stress.

In some coastal zones, winds can reach up to 138 mph during storms, lifting or damaging inadequately rated roof systems. These combined factors mean that choices suited for interior climates may deteriorate quickly near the sea.

-

Salt air, in particular, speeds up corrosion. Rust forms when salt deposits combine with moisture, weakening metal fasteners, flashing, and roofing panels faster than in dry climates.

-

This not only shortens the material's lifespan but also increases long‑term maintenance costs and the risk of leaks or structural issues.

Understanding these environmental demands is the first step in selecting roofing materials that balance durability, installation practicality, and life‑cycle value for coastal homes.

Suggested Read: Steel Roof Construction Guide for Builders and Fabricators

Let's explore the top materials that provide lasting protection and performance.

Top 5 Roofing Materials for Coastal Homes

Here are the 5 best roofing materials for coastal homes, chosen for their salt‑air resistance, wind performance, moisture endurance, and long service life in coastal environments where durability matters most:

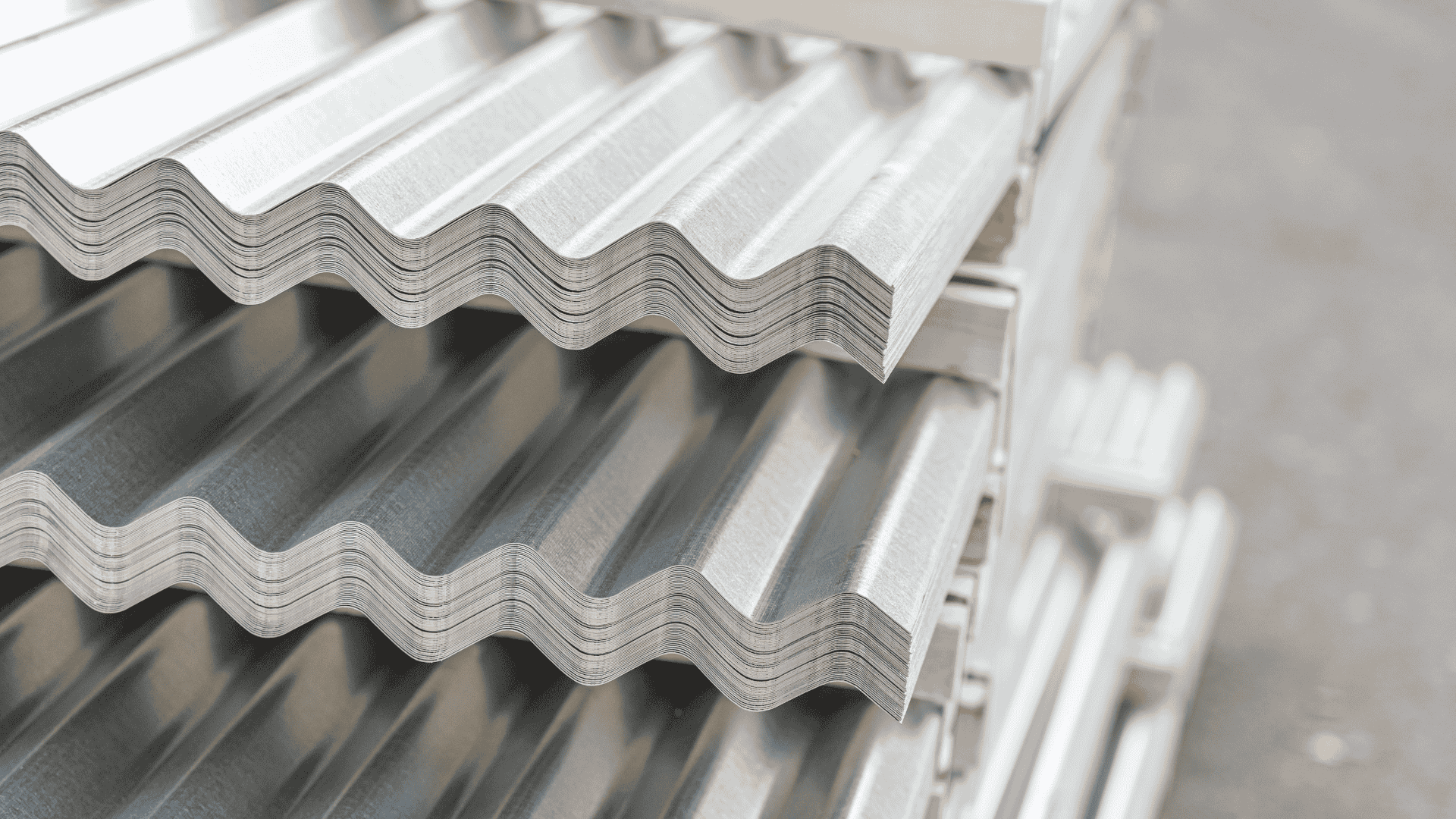

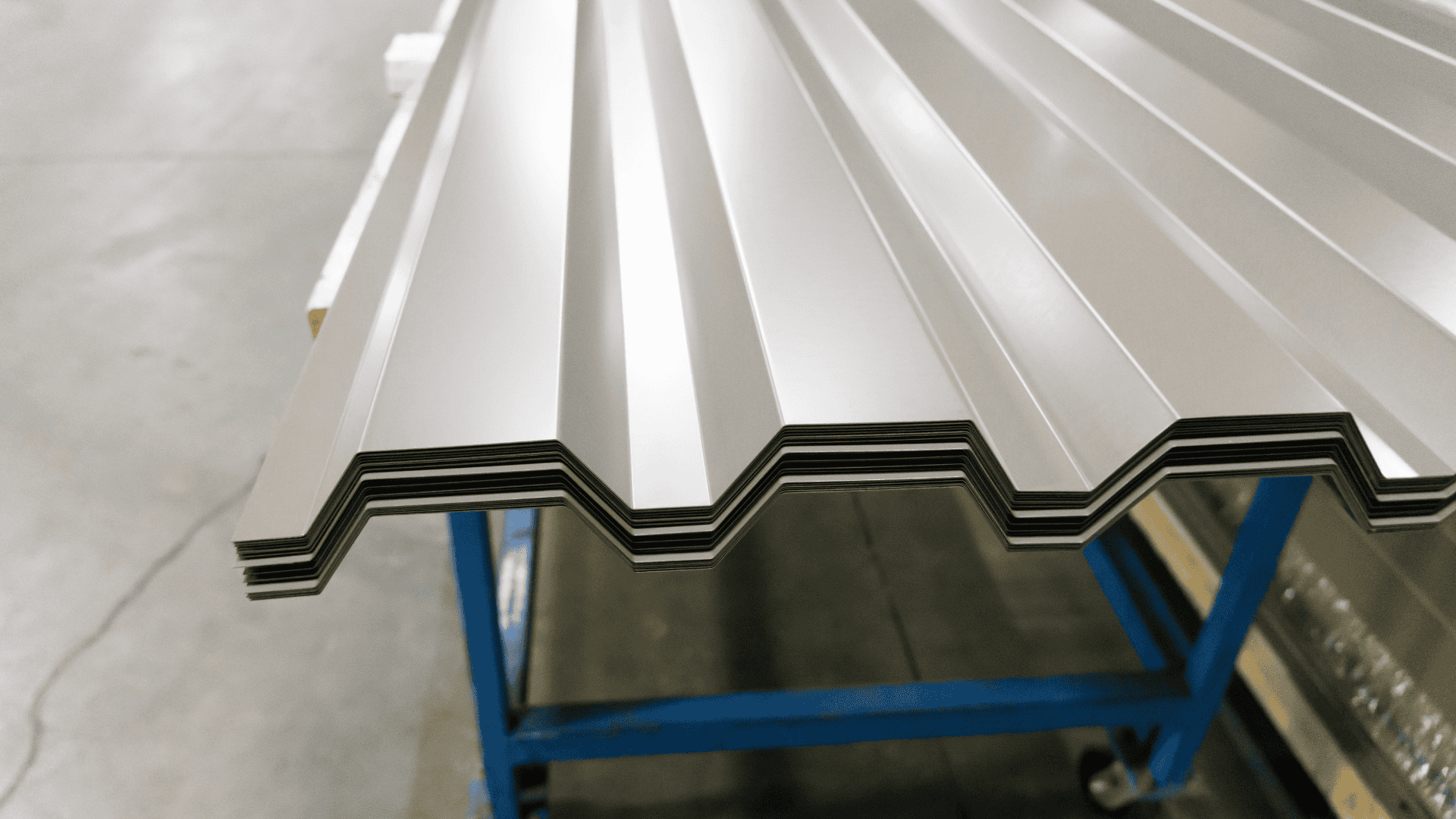

1) Standing Seam Metal Roofing

Metal roofing systems, especially aluminium or zinc‑aluminium coated (Galvalume) panels, are widely recognised as the best overall choice for coastal homes. These materials resist rust and slow salt corrosion, while panels with standing-seam profiles are rated for high wind uplift and shed moisture efficiently.

-

Lifespan: Typically 60 years (or more with proper coatings)

-

Why it works: Corrosion resistance, strong wind performance, and low maintenance make this ideal for sea‑facing builds.

2) High‑Quality Clay or Concrete Tiles

Clay and concrete tiles naturally resist moisture and salt exposure, making them durable in wet, humid coastal climates. These materials can last 50+ years when properly installed and anchored, and their mass helps keep them secure in strong coastal winds.

-

Best for: Projects where thermal performance and longevity outweigh structural load concerns

-

Note: A heavier weight may require stronger roof framing.

3) Stone‑Coated Metal Roofing

Stone‑coated metal combines the strength of metal with a UV‑stable protective layer that improves corrosion resistance and aesthetics. Many stone‑coated systems are also designed for wind-uplift resistance, similar to standing-seam profiles, thereby extending lifespan in coastal conditions.

-

Why it matters: Blends long service life with design flexibility.

4) Advanced Synthetic (Composite) Roofing

Modern composite or synthetic roofing materials, engineered from polymer, rubber, or fibre blends, offer excellent moisture and salt resistance, UV stability, and often Class 4 impact and high-wind ratings. These products are a lighter alternative and resist cracking or corrosion typical in coastal environments.

-

Note: Often lower maintenance and better thermal performance than traditional alternatives.

5) Premium Copper Roofing

Copper roofing has one of the longest track records for corrosion resistance, developing a protective patina that shields the metal and slows further corrosion, which can be especially advantageous near salt air.

-

Best for: High‑end applications or long‑term investment builds

-

Consideration: Higher upfront cost and specialised installation.

Now, why does all this matter for South India coastal builders?

Coastal climates along Andhra Pradesh, Karnataka, and Kerala experience high humidity, salt spray, monsoon rains, and intense UV exposure, conditions that cause many standard roofing systems to degrade prematurely.

Choosing materials engineered for these stresses, especially aluminium and coated steel roofing systems, improves long‑term performance and reduces maintenance cycles over the life of the project.

Now, let's focus on how to evaluate and select the right roofing solution for your specific coastal project needs.

How to Choose the Right Roofing Material for Your Coastal Project

Choosing the right roofing material for coastal homes goes beyond aesthetics. The selection must be rooted in how each material performs under salt corrosion, high‑speed winds, heavy rainfall, and UV exposure. These conditions are typical for South India's coastal belt.

The following factors help you evaluate and compare roofing options against real project needs.

1. Corrosion Resistance & Material Composition

Salt‑laden air at the coast accelerates corrosion, especially in ferrous metals that lack protective finishes.

Materials like aluminium, marine‑grade coated steels (e.g., zinc‑aluminium alloys), and clay/concrete tiles resist salt corrosion far better than uncoated metals or standard asphalt systems. Selecting non‑rusting or highly coated materials significantly increases roof life near the sea.

2. Wind Uplift Ratings & Structural Performance

Coastal regions often experience gusts over 100 mph during storms and heavy monsoon winds; roofs must be rated to withstand these loads.

Materials with interlocking panels (metal roofing) or heavy, anchored tiles provide better resistance against uplift and detachment than loosely attached products. Wind‑resistant roofing helps protect overall structural integrity and reduces rework after severe weather.

3. Moisture & Rain Durability

Monsoon seasons bring prolonged moisture exposure. Roofing materials should be non‑porous and water‑shedding, with systems designed to channel water quickly to gutters and away from the structure.

Metals with proper coatings and tile profiles that direct rainfall are more effective than porous asphalt systems, which can trap moisture and degrade faster in humid environments.

4. Thermal & UV Performance

Sun exposure in coastal South India can be intense. Roofing materials with reflective or light‑coloured surfaces reduce heat gain and help moderate indoor temperatures, lowering cooling loads.

Metals and reflective synthetic systems outperform dark asphalt and non‑reflective surfaces in UV resistance and heat management, offering better long‑term comfort and energy efficiency.

5. Maintenance Needs & Lifecycle Value

Consider how often a roofing system will need inspection, repainting, or protective upkeep. Materials with inherently low maintenance, such as aluminium, stone‑coated metals, and synthetic composites, deliver better lifecycle value in corrosive environments.

Factoring expected service life vs. maintenance frequency helps plan long‑term project costs and avoid frequent rework.

By aligning these factors with site conditions and project goals, you ensure roofing choices that deliver performance, reduce maintenance, and improve durability for coastal home projects.

Also Read: Things To Know Before Buying Metal Sheets For Roofing

Let’s understand how these materials perform in the real coastal environments of South India.

Roofing Material Performance in South India's Coastal Zones

Coastal zones in South India, from Visakhapatnam down to Udupi and beyond, face some of the most demanding roofing conditions in the country.

For example, the Udupi district in coastal Karnataka experiences intense monsoon downpours that test waterproofing and drainage systems. Long monsoons, coupled with persistent salt‑laden sea breezes, accelerate corrosion and moisture stress on roofing surfaces.

On the East Coast (e.g., Andhra Pradesh), homes experience prolonged high humidity and salt air exposure, which accelerates metal oxidation and undermines sealants if the materials aren't designed for marine conditions.

On the west coast (Karnataka/Kerala), heavy rainfall and persistent humidity mean roofing materials must shed large volumes of water quickly and resist moisture ingress that can weaken underlayments over time.

This regional climate profile has three practical performance implications for roofing choices in coastal projects:

-

Corrosion Resistance is Non‑Negotiable:

Salt aerosol combined with high moisture levels can degrade unprotected metals and coatings faster than in inland climates. Materials rated for marine environments or with enhanced coatings (e.g., high‑performance zinc/aluminium metallic layers) significantly slow corrosion.

-

Moisture Management is Critical:

Areas with around 2,000–3,000mm of rainfall, such as the Western Ghats, require roofing systems that quickly channel water and prevent ponding, which is essential for long life and leak prevention.

-

Wind & Rain Combination:

While South India's coasts don't experience perennial hurricane conditions like some global coasts, seasonal cyclonic storms and monsoon gusts can still exert wind pressures of 100+ km/h. Uplift resistance and secure fastening are important design considerations.

For project teams, these factors mean material performance must be evaluated against real climate data, not just generic specifications. This will avoid premature failures, unscheduled maintenance, and increased life‑cycle costs in coastal residential builds.

How SteelonCall's Online Marketplace Supports Coastal Roofing Projects

SteelonCall is a digital steel marketplace designed to support construction and fabrication projects in demanding environments, especially coastal regions where material performance, quality assurance, and delivery reliability are critical.

For roofing projects along South India's coasts, where salt air, humidity, and intense rainfall pose serious challenges, SteelonCall offers key advantages:

-

Verified Supplier Network for Quality Assurance

SteelonCall connects you to 250+ verified suppliers, ensuring that materials such as coated metal sheets and aluminium roofing are of trusted quality. This reduces the common risks of substandard material or incorrect grades.

-

Direct Access to Trusted Manufacturers

By offering direct sourcing from trusted manufacturers, including Vizag Steel and TATA TISCON, SteelonCall guarantees brand authenticity and consistent material grade supply.

-

Strong Regional Presence in Coastal Markets

With a deep operational presence in Andhra Pradesh and Karnataka, SteelonCall is well‑positioned to handle local demand for coastal projects. This regional focus allows for better delivery planning and a smoother procurement process.

-

Support for Bulk and Custom Grade Requirements

Coastal projects often require specific grades and sizes of roofing materials, whether for resistance to heavy rainfall or wind uplift. SteelonCall supports bulk orders and custom-grade requests, ensuring that project teams get exactly what they need.

-

End‑to‑End Logistics Coordination

SteelonCall manages the entire logistics chain, from supplier dispatch to on‑site delivery. This reduces handling risks, ensures timely delivery, and supports safe material movement, which is especially important in coastal areas.

SteelonCall is the only brand to provide live steel prices and availability online. Enter your pin code today and get the details online.

Conclusion

Selecting the right roofing material for coastal homes requires careful consideration of environmental factors like salt air, high winds, and heavy rainfall. By understanding the unique challenges posed by coastal climates in South India, you can make informed decisions that ensure long‑term durability and reduced maintenance costs.

Choosing materials with high corrosion resistance and wind performance, such as aluminium, stone‑coated metal, or clay tiles, can significantly extend your roof's longevity and improve its performance in harsh coastal conditions.

SteelonCall provides direct access to verified suppliers and trusted manufacturers, including Vizag Steel, ensuring high‑quality, corrosion‑resistant roofing solutions. Check live pricing and availability of coastal roofing materials and TMT grades today to secure the best options for your project and ensure timely delivery.

FAQs

1) Do certain roofing fasteners make a difference in coastal roofs?

Yes. In coastal climates, corrosion‑resistant fasteners (e.g., stainless steel or Class 3/4 coated screws) significantly extend roof life because ordinary screws can corrode quickly in salt‑laden air. Using the right fasteners prevents rust and leak points.

2) Can standard asphalt shingles work for coastal homes?

Standard asphalt shingles typically perform poorly near the coast because salt air and humidity accelerate deterioration. Even coastal‑rated shingles usually last less than 30 years, much shorter than metal or tile options.

3) What's the real benefit of aluminium roofing near the sea?

Aluminium is well-suited to coastal roofs because it doesn't rust (unlike regular steel) and naturally forms a protective oxide layer. This gives it strong long‑term salt corrosion resistance compared with most other metals.

4) Are clay tiles a good choice for coastal homes in India?

Yes. Clay tiles, including traditional types like Mangalore tiles, perform well in heavy rain and salt‑air environments because they resist moisture and salt deterioration and can last decades when properly installed at an appropriate slope.

5) Does coastal salt air affect roof coatings or finishes?

Absolutely. Salt air can accelerate corrosion in coatings, degrade paint, and wear finishes faster than inland climates. Choosing materials with marine‑grade or high‑performance coatings helps maintain appearance and protection longer.