What is C Channel Steel? Uses & Benefits for Construction Projects

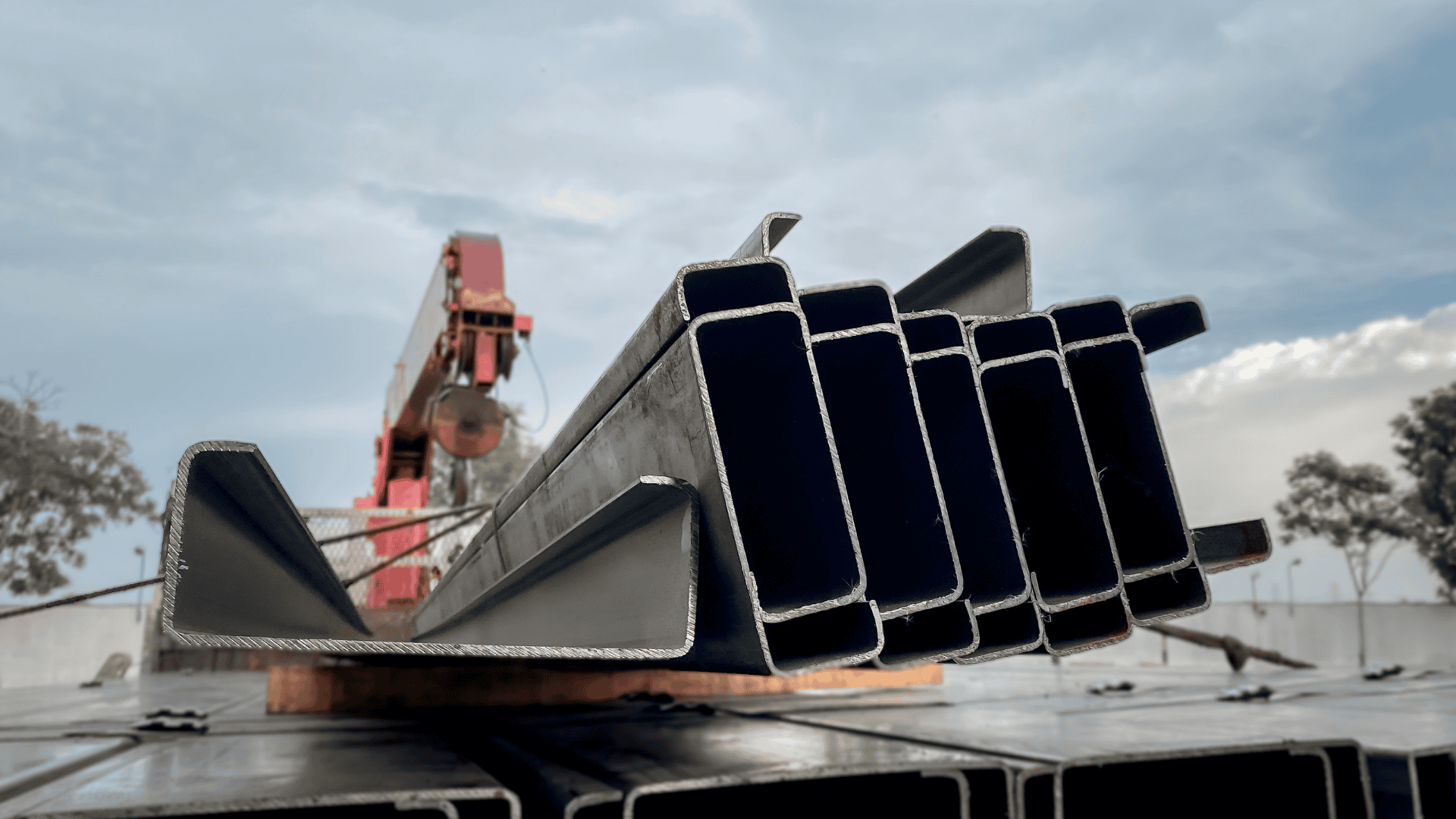

When it comes to construction projects, the materials you choose can significantly impact both the quality and efficiency of your build. Among the various types of steel used in construction, C Channel Steel stands out as a versatile and cost-effective option.

Known for its unique "C" shape, this steel product is favoured for its strength, durability, and adaptability in a wide range of applications. Whether you're working on structural frameworks, support beams, or other crucial components, understanding what C Channel Steel is and how it benefits your project is essential.

This blog will explore the uses and advantages of C Channel Steel to help you make informed decisions when selecting materials for your construction needs.

Key Takeaways:

-

C channel steel is ideal for framing, supports, and secondary structures, offering a balance of strength and ease of installation.

-

It provides a high strength-to-weight ratio, supporting significant loads while being lighter than other beams.

-

Cost savings come from faster installation and reduced material waste, making C channels a practical choice for projects.

-

For coastal areas, galvanised C channels provide superior corrosion resistance against humidity and salt exposure.

-

Overall, C Channel Steel is an excellent choice for reliable, cost-effective steel sourcing in construction and fabrication projects.

What is C Channel Steel?

C channel steel, also called structural channel or C‑beam, is a structural steel profile shaped like the letter "C," with a vertical web and two horizontal flanges extending from one side of the web. This design gives it a flat back and open face, making it easy to mount, weld, bolt, or join to other structural elements without extra brackets.

In construction and fabrication, C-channel steel is not just another beam. Its profile delivers a balance of strength and manageability, so it supports loads effectively while being easier to handle on site than heavier alternatives.

This is especially useful for framing, supports, and secondary structural members.

Why C Channel Matters in Construction & Fabrication

C-channel steel is widely used in structural and fabrication work because it offers a practical combination of strength, versatility, and efficiency that aligns with real project requirements.

Its design, with a vertical web and flanges forming a "C" shape, provides a high strength-to-weight ratio, meaning it can support significant loads without adding excessive mass to the structure. This balance is especially useful on sites where load support must be reliable but handling and installation need to be efficient.

Here's how C channel steel adds value in construction and fabrication:

-

Efficient Load Support: Its profile effectively handles vertical loads, making it suitable for framing walls, roofs, floors, and support beams where heavy-weight distribution matters.

-

Ease of Handling and Installation: Because C-channels are lighter and easier to handle than many other structural sections, crews can quickly cut, drill, weld, or bolt them into place, reducing labour time and on‑site complexity.

-

Versatility Across Applications: From structural framing in buildings to purlins for roofing and bracing systems in industrial sheds, C channels adapt to a wide range of structural needs without frequent section changes.

-

Cost and Efficiency Gains: The combination of manageable weight, ease of fabrication, and adaptability often leads to lower transportation and labour costs compared with heavier or more complex profiles.

Because of these traits, C channel steel is often chosen where projects demand solid performance without unnecessary material bulk.

Suggested Read: What is Fabrication steel and their types

With a solid understanding of its advantages, let's explore the specific applications of C-channel steel to enhance the efficiency and stability of your construction projects.

C Channel Steel Uses (Project‑Focused Applications)

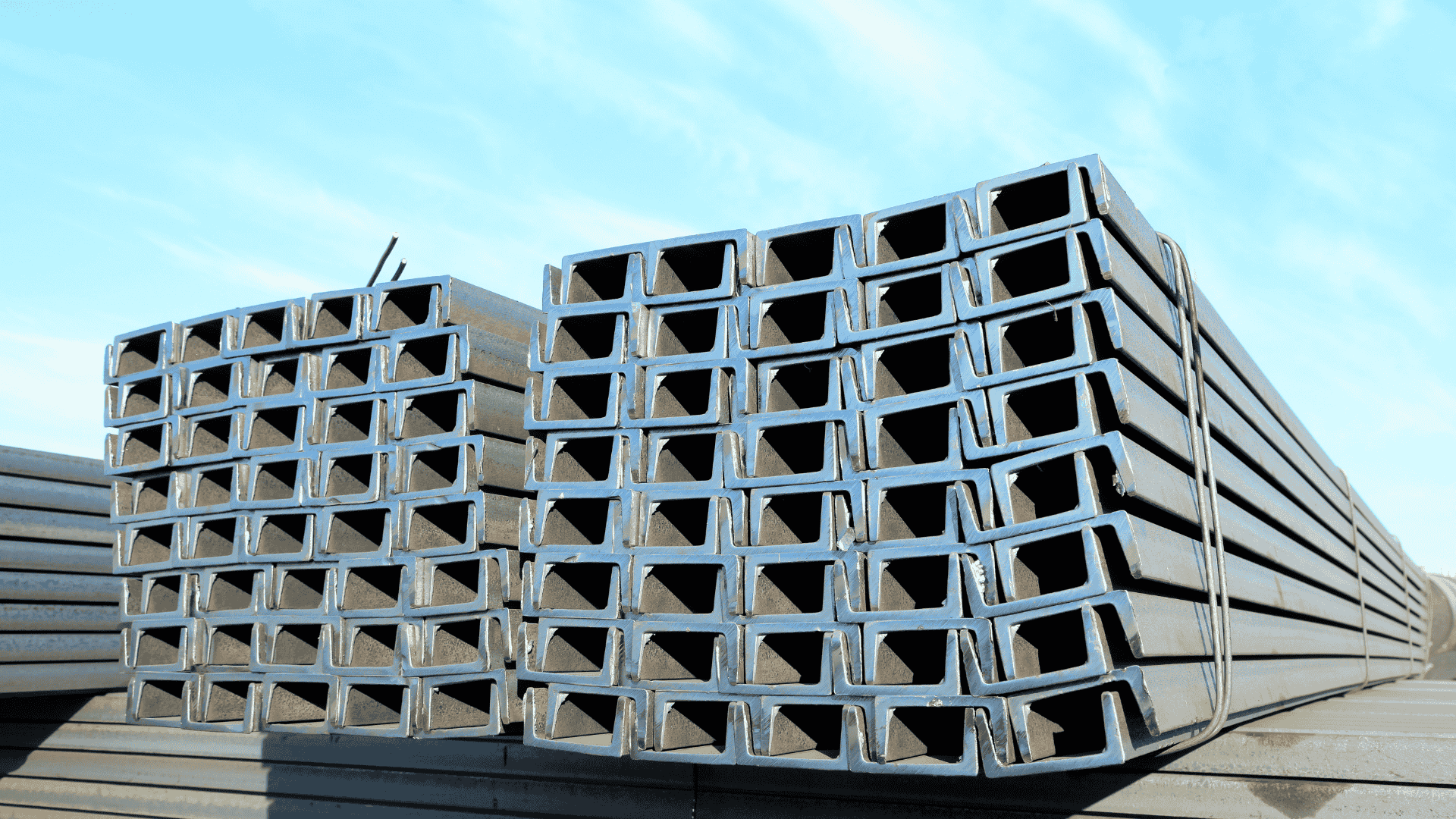

C-channel steel is a highly versatile structural product with multiple practical applications in construction and fabrication projects. Its C‑shaped profile is particularly useful where straightforward structural support, easy mounting, or a flat back surface is needed.

Contractors and project managers often select C-channels for components that require reliable load‑bearing capacity without the complexity of heavier structural sections.

1) Structural Framing and Wall Studs

C-channel steel is commonly used as vertical and horizontal framing members in building structures, where it functions similarly to studs in steel‑framed walls. Its design allows it to carry vertical loads and serve as the skeleton of industrial sheds, warehouses, and even residential buildings using steel framing systems.

2) Roof and Ceiling Supports (Purlins & Girts)

In roof systems, C channels often serve as purlins, horizontal members that support roof sheets between rafters. Their strength‑to‑weight ratio allows for wider spans between supports, reducing the number of required columns and lowering material costs.

3) Beam and Column Support Elements

When used horizontally, C channels distribute loads in floors or mezzanines; when installed vertically, they can act as secondary support columns or bracing members. These functions improve structural stability in commercial and industrial projects.

4) Window, Door, & Frame Reinforcements

C-channel steel provides a flat surface for mounting, making it ideal for lintels over door and window openings or as support reinforcements where openings interrupt primary load paths. This simplifies installation and ensures load transfer around cutouts in walls.

5) Equipment and Machinery Supports

In fabrication workshops or industrial facilities, C channels are used to create support frames for machinery, conveyors, and storage racks. Their predictable strength and ease of drilling and welding make them practical choices for custom support structures.

6) Secondary & Miscellaneous Structural Uses

Beyond primary load paths, C channels are used for brackets, railings, fencing, elevated platforms, stair stringers, and equipment anchoring. Their adaptability means they're often chosen for project‑specific solutions when standard beams are not necessary.

This real‑world usage guidance helps project teams identify when and why to specify C channel steel in their plans, especially in South India, where efficient structural components help keep busy job sites on schedule.

Now, it's important to compare C channel steel with other structural options to help you make an informed decision based on your project's needs.

C Channels vs Other Structural Sections: A Quick Comparison

Here's a practical comparison of C channel steel with other commonly used structural sections, focusing on load capacity, installation, and typical construction/fabrication uses:

| Structural Profile | Best Use Cases | Load‑Bearing & Strength | Ease of Fabrication & Installation | Typical Project Applications |

|---|---|---|---|---|

|

C Channel Steel |

Secondary framing, support members |

Moderate — suitable for medium loads (supports wall studs, purlins) |

High — lighter, easy to weld/bolt |

Roof purlins, wall studs, equipment support |

|

I Beam / W Beam |

Primary beams and heavy structural members |

Very High — excellent for long spans/heavy loads |

Moderate to low — heavier, needs careful handling |

Main beams, long‑span roof frameworks |

|

Steel Angles |

Bracing, corner supports |

Lower — strong in specific directions |

Very High — simple shape, easy to install |

Bracing, simple frames, shelving |

|

Square/Rectangular Tube (HSS) |

Columns, frames with torsional loads |

High — better torsional resistance |

Moderate — heavier than channel but stable |

Columns, load‑bearing frames |

Here's a practical decision logic to make the right choice:

-

Use C channels when you need efficient structural support without heavy load demands, especially in roofing, wall framing, and mezzanine supports.

-

Choose I beams when primary load capacity and long spans are required.

-

Go with angles for reinforcement and bracing.

-

Specify HSS shapes for columnar loads and torsion‑sensitive frames.

This comparison helps contractors and project managers quickly gauge which steel profile fits a given task, making procurement planning more predictable and aligned with structural requirements.

Also Read: Different types of steel are used for different construction needs

Practical Design & Selection Considerations for Contractors and Engineers

To help you choose and detail C Channel Steel on real projects, here are specific numbers and behaviours contractors and engineers care about.

Typical C Channel Sizes & Weights

Common mild steel channel (ISMC) sizes (depth × width × thickness) and approximate weight per meter are:

-

ISMC 75×40×4.8 mm → ~7.1 kg/m — light supports, partitions.

-

ISMC 100×50×5.0 mm → ~9.6 kg/m — modest framing, light purlins.

-

ISMC 125×65×5.3 mm → ~13.1 kg/m — wall framing, mezzanine light supports.

-

ISMC 150×75×5.7 mm → ~16.8 kg/m — roof purlins with moderate spans.

-

ISMC 200×75×6.2 mm → ~22.3 kg/m — stronger beams or bracing.

-

ISMC 250×82×9.0 mm → ~34.2 kg/m — heavier support framing.

These figures help in material take‑off and logistics planning.

Bolting vs Welding Behaviour

-

Bolting to C-channels (especially pre‑drilled holes) is quick and avoids local heat input, thereby preserving material properties. It is ideal for secondary members and removable assemblies.

-

Welding is stronger for continuous load paths but requires careful heat control near the web to avoid distortion or local buckling.

Channels, unlike closed sections, have open flanges that can warp if overheated, so consistent welding procedures and pre‑fit checking are important.

Lateral Torsional Buckling (LTB)

Channels, being open‑section shapes, have lower torsional rigidity than closed or wide‑flange beams. Under unbraced loading (e.g., long unsupported horizontal spans), they are more susceptible to lateral torsional buckling, a mode where the channel twists laterally before load capacity is reached.

This is why:

-

Shorter-span applications (roof purlins, wall studs) often work well without full lateral restraints.

-

Longer spans or heavy loads often require either brace points or a switch to deeper I‑beams for primary load paths.

Having listed the key design aspects to consider, let's look at the crucial factors that will help you choose the right C-channel steel for your specific project.

Choosing the Right C Channel for Your Project

Selecting the right C channel steel isn't just about picking the biggest or cheapest section. It's about matching the section's strength, size, and treatment to the structural demands, environmental conditions, and installation realities of your project.

A well‑chosen channel reduces over‑engineering (and material waste), ensures structural reliability, and keeps procurement predictable.

Below is a practical checklist of key factors to consider when choosing C channel steel for construction or fabrication work:

1. Load Requirements & Structural Role

Evaluate how much load the C channel must support, both static loads (e.g., weight of structure) and dynamic loads (e.g., equipment vibration or wind uplift).

-

Larger web height and thicker flanges increase load‑bearing capacity and stiffness. This improves resistance to bending and shear forces, especially when channels act as beams or long‑span supports.

-

Projects requiring higher loads (industrial sheds, mezzanine levels) typically call for deeper, heavier sections; lighter channels work for partitions and secondary supports.

2. Span and Support Spacing

The distance between supports affects how much bending stress a channel experiences. Wider spans usually require larger or stronger channel sections.

-

If your project spans long distances (e.g., roof purlins over a warehouse bay), consider channels with higher section modulus. This improves resistance to deformation under load.

-

In structural design charts, section modulus and moments of inertia are used to ensure that deflection limits are met for a chosen span.

3. Environmental Exposure & Corrosion Resistance

Assess exposure to moisture, humidity, and corrosive elements. For outdoor structures in coastal or high‑rainfall areas (common in South India), galvanised C channels with zinc coating provide superior corrosion resistance.

-

Plain carbon steel is suitable for interior applications with limited exposure, but it isn't ideal where rust or oxidation can undermine performance.

-

Coated or galvanised channels help extend service life and reduce maintenance costs, especially for long‑term load‑bearing applications.

4. Material and Surface Treatment Options

It is crucial to choose the right finish and steel channels based on site conditions, expected exposure, and lifecycle considerations - not just first‑cost.

-

Hot‑rolled steel channels are widely used in general construction for balanced strength and cost‑efficiency.

-

Galvanised channels add a protective layer, improving lifespan in outdoor or exposed environments.

-

Stainless steel channels are best where corrosion and chemical exposure are significant concerns.

5. Fabrication and Installation Compatibility

Consider how easily the chosen C channel can be cut, drilled, welded, or bolted. Channels with standardised hole patterns or pre‑punched options speed up installation and reduce on‑site labour time.

-

Ensure the selected section is compatible with your welding procedures and fastening systems to avoid delays once the material arrives on site.

-

Compatibility with common construction tools and labour skillsets improves site productivity.

6. Budget and Lifecycle Value

While upfront cost is important, consider lifecycle cost, including durability, maintenance, and replacement risk.

-

Heavier or coated sections may cost more initially, but reduce long‑term project risks by resisting corrosion and deformation.

-

Avoid oversizing (which adds unnecessary material cost) or undersizing (which risks performance failures).

7. Consult Structural Load Charts or Engineers

For critical structural roles, especially where safety is non‑negotiable, refer to load charts or consult a structural engineer. This ensures your choice meets safety standards and local codes.

-

Engineers factor in variables such as load type, bending moments, and deflection limits to match channels to performance expectations.

All in all, this checklist ensures structural reliability, predictable performance, and material efficiency - all of which are essential for meeting site schedules and budgets.

How SteelonCall Makes Sourcing C Channel Steel Smarter

SteelonCall is an online steel marketplace that connects buyers directly with verified suppliers and trusted manufacturers, making C-channel steel procurement faster, more reliable, and cost-efficient.

For projects, especially in coastal areas, where delivery timelines, material performance, and product authenticity are critical, SteelonCall is the ideal solution.

Here's why SteelonCall is the smart choice for sourcing C channel steel:

-

Verified Supplier Network for Quality Assurance

SteelonCall works with 250+ verified suppliers, ensuring that every product listed, including C channel steel, meets stringent quality standards. For projects where substandard materials can cause delays or even structural risks, this verification process is a key differentiator.

-

Direct Access to Trusted Manufacturers

Buyers can source C-channel steel directly from leading manufacturers, including Vizag Steel. For coastal projects, where material corrosion resistance and long-term reliability are crucial, direct manufacturer access eliminates the uncertainty that comes from dealing with intermediaries.

-

Strong Regional Presence in Coastal Markets

SteelonCall has a strong presence in Andhra Pradesh, Telangana, and Karnataka, which are home to numerous coastal construction projects. This regional focus ensures SteelonCall is attuned to local market conditions, demand patterns, and logistical nuances.

-

Support for Bulk and Custom Grade Requirements

Coastal projects often require specific grades or non-standard sizes for steel components. SteelonCall supports bulk orders and custom grade requests for C-channel steel, enabling project teams to align procurement with precise structural needs.

-

End-to-End Logistics Coordination

SteelonCall handles logistics from supplier dispatch to site delivery, reducing handling risks and ensuring timely deliveries. In coastal regions, where transportation can be affected by high humidity and salt exposure, SteelonCall's managed logistics provide an added layer of reliability.

SteelonCall's online marketplace model removes the complexity from sourcing steel, offering a seamless experience that combines quality assurance, competitive pricing, and logistical reliability.

With 9,600+ customers, 8,560+ orders processed, and ₹3,360+ million in turnover, SteelonCall is a trusted partner for your steel needs, especially in demanding environments like coastal construction.

Wrapping Up

Sourcing C channel steel for construction and fabrication has become a crucial decision that impacts both project timelines and costs. By understanding the material's strengths, load capacity, and fabrication needs, you can make better choices that align with your project's requirements.

However, incorporating C channel steel into your project doesn't have to be complicated. With SteelonCall, you get real-time pricing, verified suppliers, and reliable delivery to ensure your steel sourcing is seamless and cost-effective.

Ready to take the next step? Get real-time pricing and availability for steels and TMT grades today and secure the materials you need with predictable pricing and on-time delivery.

FAQs

1) How do C-channel steel sizes impact load capacity on site?

C-channel steel size, including web depth, flange width, and thickness, directly affects the load it can support. Larger sections with greater depth and flange area resist bending and deflection better, especially in roof purlins or framing applications.

2) Can C-channel steel be welded or drilled on-site without weakening the section?

Yes, C channel steel (especially hot‑rolled carbon steel) is designed to be welded and drilled during installation. Standard fabrication practices ensure structural integrity remains intact when you make connections or add bolt holes.

3) What's the difference between a C channel and an MC channel for structural use?

The main difference is in the flange design: C channels have equal perpendicular flanges, while MC channels may have heavier flanges. This can affect how they distribute loads and connect to other members.

4) Are there standard length options for C channel steel deliveries?

Yes, C channel steel is typically stocked in standard mill lengths, often 20 ft or 40 ft, and can be cut to exact sizes as required, helping optimise material usage and reduce site cutting work.

5) Is C channel steel corrosion‑resistant for coastal or outdoor projects?

Plain C-channel steel isn’t inherently corrosion‑resistant, but galvanised or coated versions can provide strong protection against rust and weathering, which is important in coastal or high‑humidity environments.