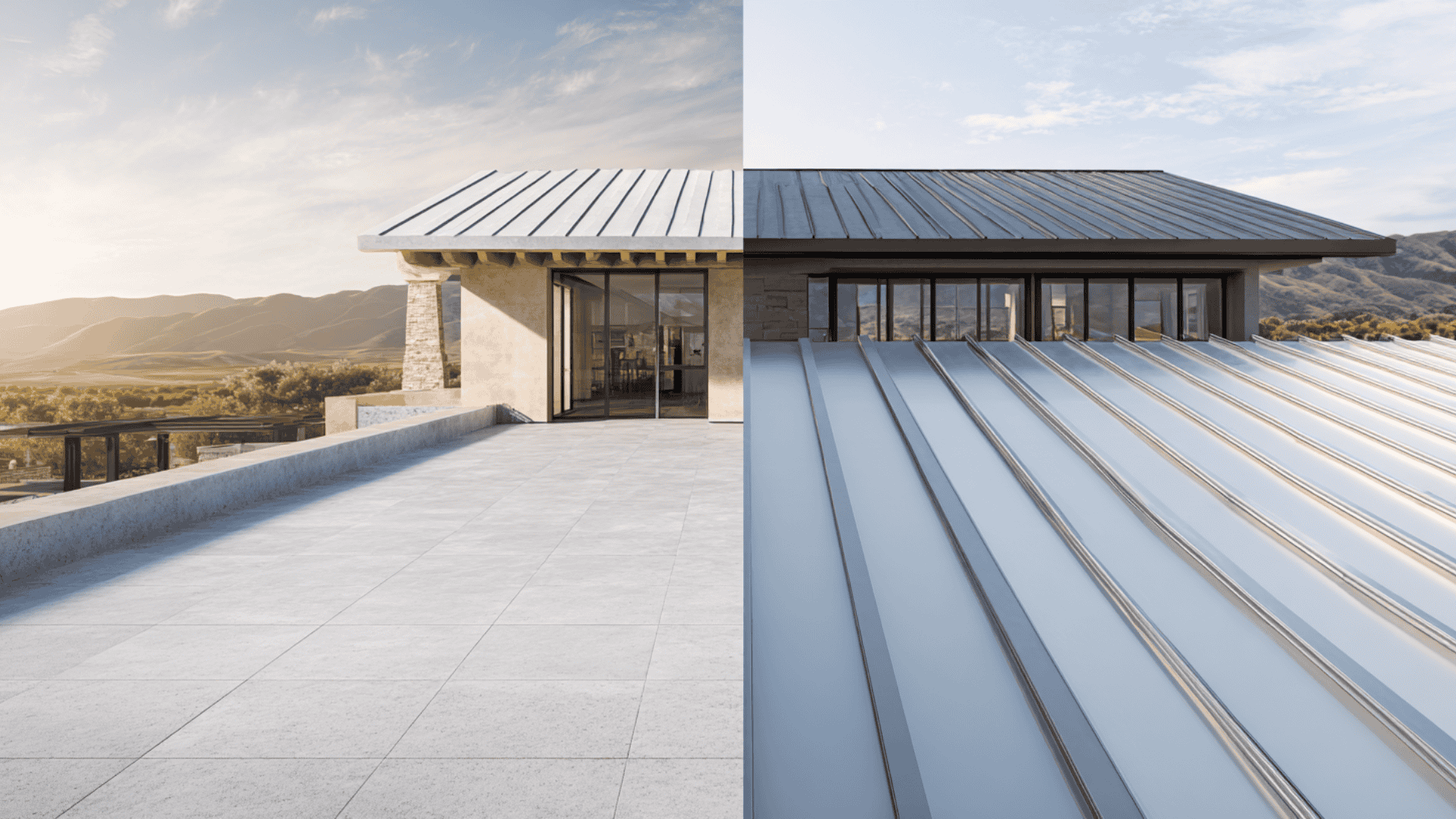

Concrete Slab Roof vs Metal Roof: Cost & Durability Comparison

When it comes to choosing the right roofing material, the pressure to meet tight deadlines and stick to budget is real. Contractors and project managers face constant stress from fluctuating prices, delays, and the fear that materials will not arrive on time, potentially throwing off the entire project schedule.

On top of that, sourcing steel can often feel like figuring out a maze of middlemen and unverified suppliers, each introducing more risk and uncertainty. But it doesn't have to be this way.

This blog breaks down the cost and durability differences between a concrete slab roof vs metal roof, helping you make a smarter, more reliable choice. By the end, you'll know how to sort through these common challenges, ensuring your next roofing project is both cost-effective and on time without compromising quality.

Key Takeaways:

-

Concrete Slab Roofs provide long-term durability and are ideal for heavy load-bearing and thermal mass.

-

Metal Roofs are faster to install and cost-effective, perfect for quick builds or lighter structures.

-

Concrete roofs take longer to install, while metal roofs can be set up in days.

-

Both roofing types perform well in coastal and humid conditions, but metal roofs need regular maintenance to avoid corrosion.

-

Metal roofs offer better heat reflection, while concrete roofs provide superior fire resistance.

Concrete Slab Roof vs Metal Roof: Cost & Durability at a Glance

Choosing between a concrete slab roof and a metal roof isn't always a straightforward decision, especially when considering long-term project timelines, costs, and specific site conditions.

In South India's construction industry, where projects often face tight deadlines, fluctuating material costs, and the need for durable, weather-resistant structures, these two options each have their strengths.

Here's just a quick glance at the comparison:

Concrete Slab Roof

-

Typical Cost (India): ₹180 – ₹250 per sq ft installed (materials + labour), depending on location and scale.

-

Durability: High structural strength with long service life with proper maintenance; excellent fire resistance and load support capacity.

-

Best For: Projects needing heavy load support (e.g., rooftop utilities), thermal mass, and long‑term durability.

Metal Roof (Steel Roof Sheets)

-

Typical Cost (India): ₹120 – ₹220 per sq ft installed (materials only; installed cost varies with framing and labour quality).

-

Durability: Good lifespan when correctly coated and maintained; easier to replace or upgrade.

-

Best For: Projects prioritising speed of installation, lighter structure, and quicker site closure.

When to Lean Toward Each Option?

| Factor | Concrete Slab Roof | Metal Roof |

|---|---|---|

|

Initial Cost |

Higher (due to labour, formwork, reinforcement) |

Lower to Moderate (lighter materials; faster install) |

|

Durability |

Very High |

Good |

|

Installation Time |

Longer (multiple phases) |

Faster (days vs weeks) |

|

Structural Load |

Excellent |

Moderate (needs good framing) |

|

Maintenance |

Minimal ongoing work |

Occasional coating/repair |

|

Suitability |

Permanent buildings, terraces, heavy loads |

Industrial sheds, site offices, quick covers |

For long‑term structural roofs with heavy use (e.g., terrace slabs or service decks), the durability and fire resistance of a concrete slab roof usually justify its higher cost.

For lightweight, quicker builds where speed and cost control matter, such as industrial sheds or temporary site structures, metal roof sheets can be highly practical.

This quick comparison sets the stage for deeper discussion on project priorities, cost‑benefit considerations, and how to factor in your specific site needs.

Also Read: What is the relationship between Steel and concrete?

Understanding Each Roofing Option

When deciding between a concrete slab roof and a metal roof, it's essential to understand how each option performs in real-world construction settings. Understanding these two roofing options will help you make an informed decision based on your project's priorities.

So let's get an in-depth idea of what each one actually is.

What Is a Concrete Slab Roof?

A concrete slab roof is a flat roof built with reinforced cement concrete (RCC) that serves as both the structural roof and, in many cases, the finished deck. In practice, this means formwork and reinforcement bars are placed, followed by concrete placement and curing until the concrete reaches structural strength.

It is not just a layer of concrete. It's an integrated structural element that also affects load distribution and the building's thermal mass.

-

Structural Role: Provides roof support and can carry heavy loads like water tanks, solar panels, HVAC systems, or utility platforms without needing additional framing.

-

Installation Timeline: Involves multiple phases, such as setting up shuttering/formwork, placing and tying reinforcement (typically Fe 500D/550D grade bars in modern construction), casting concrete, and curing for strength. This contributes to longer installation durations compared to sheet roofing.

Concrete slabs also offer inherent fire resistance and are less prone to deformation under sustained loads. These strengths make them a preferred choice for residential complexes, multi‑storey buildings, and structures where long‑term durability and heavy service loads matter.

What Is a Metal Roof?

A metal roof is roofing made from metal panels or sheets, most commonly steel, in construction settings. These can be plain galvanised steel or colour‑coated steel with protective paints that enhance corrosion resistance and aesthetic appeal.

-

Material Profile: Steel roofing sheets used in construction vary by gauge, coating type (galvanised, galvalume, or high‑paint finishes), and panel profile (corrugated, trapezoidal). These factors directly influence strength, durability, and ease of installation.

-

Installation Speed: Metal roofs are lighter and much quicker to install than concrete slabs; depending on project size, they can be installed in days rather than weeks. This can significantly shorten project timelines, an important consideration for urgent site handovers.

Metal roofs also perform well in terms of rain shedding and wind resistance when installed with proper clips and fasteners. Their lightweight nature reduces the need for heavy structural framing, which can translate into cost savings on foundations and support members.

This helps contractors and project managers immediately grasp how each roofing option behaves on site, the real implications for cost, timeline, and structural planning.

Concrete Slab Roof vs Metal Roof: Cost Breakdown for Real Projects

When planning a roofing solution, understanding the true cost components, materials, labour, and installation is central to project budgeting and supplier negotiation. In Andhra Pradesh, Telangana, and Karnataka, roofing decisions often hinge on these cost trade‑offs, especially for mid‑ to large‑scale structures.

1) Concrete Slab Roof Cost (RCC Flat Roof)

A reinforced concrete roof (RCC slab) combines concrete, steel reinforcement, shuttering, and labour. On average, construction practitioners in India estimate the cost for a roof slab per square foot (including material and labour) at:

-

₹180 – ₹250 per sq ft for a standard RCC roof slab in non‑premium locations.

-

In metro or high‑demand city projects (e.g., Hyderabad or Bengaluru), this figure can exceed ₹300 per sq ft due to higher labour and formwork charges.

This range reflects the combined material stack, cement, sand, aggregate, reinforcement steel (e.g., Fe 500D/550D), and labour/shuttering, and varies by project complexity.

2) Metal Roof Cost (Steel Roofing Sheets + Structure)

Metal roofs, commonly fabricated from galvanised or colour‑coated steel sheets, comprise the sheet material, the framing/support structure, and installation labour. Current market observations from supplier listings and pricing data indicate:

-

Standard metal roofing sheets can typically range from ₹120 – ₹220 per sq ft installed (materials only; installed cost varies with framing and labour quality).

-

Some premium-grade PPGI/colour‑coated profiles can reach ₹150 – ₹220 per sq ft in regions like Bengaluru and Hyderabad.

-

For sloping or framed structures, total installed costs (sheet + supports + fasteners + labour) often range from ₹200 – ₹300+ per sq ft, depending on design and site factors.

However, this is all based on real installer estimates from local discussions and contractor quotes.

While metal roofs often look cheaper at the material level, the full installed cost should be evaluated, especially on structural sheds, industrial sites, or buildings that require careful integration of steel profiles or support systems.

Now, let's get into durability and performance comparisons to help you balance cost with long‑term value for your specific project needs.

Durability & Lifespan: What to Expect on Site

When comparing roofing materials, service life and resistance to environmental stresses are the most practical durability measures. Both concrete and metal roofs can deliver long service lives when appropriately designed and maintained, but the mechanisms differ.

-

Concrete Slab Roofs (Reinforced):

Reinforced concrete structures are designed to last decades if durability requirements are met, including proper concrete mix design, adequate cover over reinforcement, and proper curing. In high‑corrosivity environments (e.g., coastal or high humidity), the time to corrosion initiation for rebar can be extended when specifications (water‑cement ratio, cover thickness) are controlled.

-

Metal Roofs (Steel Sheets):

Quality metal roofing systems with protective coatings can achieve a lifespan of 40–70 years or more, depending on material grade, finish quality, and maintenance practices. Durable metal roofs are designed to resist weathering and corrosion, so they perform well over several decades.

Both roofing solutions can align with long project horizons, but the specifics of environmental exposure (e.g., monsoon rains, humidity in Telangana, coastal salt spray in Karnataka) influence long‑term performance planning.

Resistance to Weather, Corrosion & Structural Stress

1) Weather & Environmental Resilience

-

Concrete Roofs: Due to their mass and stiffness, concrete roofs provide strong resistance to wind, storms, and heavy rain conditions. Their inherent thermal mass also contributes to temperature stability inside structures, which can be valuable in hot, tropical climates where daytime peaks and night‑time drops occur.

-

Metal Roofs: Modern steel roof panels are engineered to withstand heavy rain and wind loads. Their exposed surfaces typically have corrosion‑resistant coatings (galvanisation or colour coatings) that protect underlying steel from oxidation and rust. Correct specification and installation are crucial in high-humidity or coastal regions.

2) Corrosion Considerations

-

Concrete Slab Roofs: Corrosion in reinforced concrete is mainly driven by chloride ingress and carbonation, particularly in humid climates. With proper concrete design and cover over reinforcement bars, corrosion initiation can be significantly delayed — improving service life and structural integrity.

-

Metal Roofs: Steel roofing sheets rely on surface protection. Galvanised or painted coatings dramatically slow corrosion, but periodic inspection and maintenance (especially in monsoon or coastal zones) remain important to sustain performance over decades.

Fire Resistance & Safety Performance

-

Concrete Slab Roofs: Concrete is a non‑combustible material with low heat conduction, making it an excellent choice for fire-resistant roofs. This makes them a preferred choice in settings where fire safety and structural stability under heat are priorities.

-

Metal Roofs: Steel roofs do not burn, but their performance under extreme heat depends on coatings and insulation systems. Modern metal roofing materials can be specified with fire‑resistant treatments, which make them suitable for many building classes. However, unlike concrete, metal conducts heat, so the roofing system design should account for heat transmission in hot climates.

Understanding these durability profiles helps you align roofing selection with your project's lifecycle expectations, especially for building longevity and maintenance planning in Andhra Pradesh, Telangana, or Karnataka.

With durability and performance in mind, let's explore the practical decision factors that will guide your roofing choice.

Practical Decision Factors for Contractors & Project Managers

When choosing between a concrete slab roof and a metal roof, the decision goes beyond just material cost. Contractors and project managers need to consider a variety of practical factors that affect the project's budget, timeline, and long-term performance.

From installation speed to load-bearing requirements, each roofing option offers distinct advantages depending on the project's specific needs.

1) Project Timeline & Installation Speed

For many contractors and project managers, schedule pressure is a top priority.

-

Concrete Slab Roof requires formwork setup, reinforcement tying, concrete casting, and curing, which can extend the roof phase by days to weeks, depending on weather and crew size.

-

Metal Roofs are significantly faster to install since prefabricated sheets and panels are mounted on structural framing, reducing roof installation time from weeks to days in many cases. Faster installation means earlier handover and fewer on‑site delays.

Decision Insight: If your project has strict deadlines or phased occupancy, the speed advantage of metal roofs can be a decisive factor.

2) Structural Load & Use Case Requirements

The choice between materials depends heavily on load demands and roof function.

-

Concrete Slab Roofs serve as structural elements themselves, inherently capable of supporting live loads such as water tanks, solar arrays, HVAC units, or future expansions without additional framing.

-

Metal Roofs primarily serve as coverings over a support structure. Their load‑bearing capacity depends on the strength of the framing system, purlin spacing, and sheet profile design.

Decision Insight: For heavy service loads or multifunctional roof spaces, concrete slabs offer structural advantages. For light enclosures and non‑load‑bearing roofs, metal systems perform efficiently when properly framed.

3) Climate & Weather Performance

India's south, especially Andhra Pradesh, Telangana, and Karnataka, experiences monsoons, heat stress, and humidity.

-

Concrete Slabs have thermal mass that helps moderate internal temperatures by absorbing heat during the day and releasing it slowly at night.

-

Metal Roofs can offer higher reflectivity and heat rejection when specified with reflective finishes, significantly impacting internal temperatures and reducing cooling loads.

Decision Insight: In regions with intense solar exposure, selecting reflective metal roofing panels can improve energy performance. Conversely, concrete slabs may be preferable where thermal mass is critical for indoor comfort.

4) Long‑Term Maintenance and Lifecycle Risks

Durability is crucial to avoid unexpected project costs long after installation.

-

Concrete Roofs generally demand minimal maintenance once properly constructed, provided reinforcement cover and mix design align with the service environment (to protect against corrosion and weathering).

-

Metal Roofs require periodic inspection of coatings and fasteners, especially in monsoon or coastal zones, to mitigate corrosion risks and maintain waterproofing performance.

Decision Insight: Projects with limited maintenance budgets might benefit from the low‑touch nature of well‑executed concrete slabs. Metal roofs perform well, too, but need planned maintenance cycles.

5) Budget Allocation & Contingency Planning

Cost planning isn’t just about per‑square‑foot material cost; it’s about installed cost and risk contingencies.

-

Concrete slabs have a higher upfront installed cost due to the formwork and labour intensity. However, repair costs over a long life are typically low.

-

Metal roofs may offer lower material costs, but solid framing and high-quality coatings can push total installed costs close to those of concrete systems. Material cost structures for metal roofing often vary with market steel prices and coating premiums.

Decision Insight: If cash flow timing and immediate expenditures are critical, metal roofs can be more predictable. If total lifecycle investment is the primary metric, concrete slabs often offer strong long‑term value.

So, to bring it all together, follow this practical decision checklist for your quick project assessment:

| Decision Factor | When to Lean Concrete Slab | When to Lean Metal Roof |

|---|---|---|

|

Timeline |

Tight schedule not a concern |

Fast installation required |

|

Load Support |

Heavy rooftop utilities |

Standard roof loads |

|

Climate |

Need thermal mass |

Prioritise heat reflection |

|

Maintenance |

Low maintenance over decades |

Periodic coating/inspection |

|

Budget |

Long‑term cost focus |

Short‑term installed cost focus |

This structured decision framework helps you move beyond generic comparisons to choices that match project requirements, site conditions, and lifecycle expectations, allowing clearer planning and material procurement.

Suggested Read: Why is steel the most using metal in industries?

Once you've identified your roofing requirements, the next step is sourcing the right materials. Here's how to do it efficiently.

How to Source Roofing Steel Smartly for Metal Roof Projects

When sourcing steel roofing sheets for your next project, quality control, supplier reliability, and logistics are key to ensuring successful procurement and timely installation.

-

Start by specifying materials that meet BIS certification and Indian standards (IS 277:2018) to avoid subpar products. Confirm mill test certificates (MTC) to validate the chemical and mechanical properties of the sheets, ensuring they meet project specifications.

-

Beyond price, supplier evaluation should also consider factors such as stock availability, lead times, and delivery performance, especially in the fast-paced construction environment of Andhra Pradesh, Telangana, and Karnataka.

-

Effective logistics planning ensures that materials arrive on time and in good condition, keeping the project on track. By using a risk-adjusted approach, you can build a reliable sourcing strategy that leverages multiple suppliers and ensures consistency in quality and delivery.

This arms you with actionable steps to source roofing steel that aligns with project needs and mitigates supply risks, ultimately ensuring smoother execution from procurement to installation.

Why Choose SteelonCall for Your Roofing Steel Needs?

SteelonCall is a trusted online steel marketplace designed to simplify steel sourcing for construction and fabrication businesses, especially those managing metal roofing projects.

Whether you're a contractor, builder, fabricator, or project manager, SteelonCall helps you secure dependable, project-ready steel in demanding environments, including regions with specific challenges such as humidity, heat, and logistical complexity.

Here are the top 5 reasons SteelonCall stands out for your metal roofing steel needs:

-

Verified Supplier Network for Quality Assurance

SteelonCall partners with 250+ verified suppliers who undergo strict quality checks. This ensures that the steel you source meets the expected grades and standards, eliminating common risks where the steel delivered doesn't match the promised quality. -

Direct Access to Trusted Manufacturers

By sourcing directly from leading manufacturers like Vizag Steel and TATA TISCON, SteelonCall guarantees brand authenticity and a consistent supply of steel grades suitable for roofing applications. This direct access is crucial for ensuring steel quality and reducing the uncertainty often found in traditional supply chains. -

Strong Regional Presence in South India

With significant operations in Andhra Pradesh, Telangana, and Karnataka, SteelonCall has deep regional knowledge, especially in areas with high demand for roofing materials. This presence means better coordination and quicker, more reliable deliveries, critical for keeping your project timeline intact. -

Support for Bulk Orders & Custom Grade Requirements

SteelonCall supports bulk orders and custom steel grades tailored to roofing projects. Whether you need specific sheet sizes or unique coatings, SteelonCall ensures you get the exact material specifications required, without delays or compromises. -

End-to-End Logistics Coordination

SteelonCall handles the entire logistics process, making it easier to manage schedules and reduce handling risks. For metal roofing projects, this logistics oversight ensures timely, secure deliveries, crucial for maintaining project momentum.

SteelonCall is a reliable partner for sourcing high-quality steel, reducing procurement risks, and supporting on-time, on-budget project execution in South India. With over 9,600+ trusted customers and ₹3,360+ million in turnover, SteelonCall continues to redefine steel procurement for contractors, builders, and project managers.

Conclusion

Each roofing option has distinct advantages based on project requirements, from concrete's long-term durability and load-bearing capacity to metal's faster installation and cost efficiency. Understanding these differences helps contractors, builders, and project managers make informed decisions that align with project needs, timelines, and budgets.

Choosing the right roofing steel for your project is critical to ensuring long-term performance and cost control. With SteelonCall's verified supplier network and direct access to trusted manufacturers like Vizag Steel, you can secure high-quality metal roofing sheets with reliable delivery and competitive bulk pricing.

Check the latest prices and availability for roofing sheets today to keep your project on schedule and within budget.

FAQs

1. Will a concrete slab roof or a metal roof perform better in heavy monsoon conditions

Concrete slab roofs resist water penetration well when properly waterproofed, while metal roofs with proper overlaps and coatings shed rain quickly; both perform well in monsoon zones when designed and installed to local standards.

2. Do metal roofs require special framing compared with concrete slab roofs?

Yes — metal roofs are lightweight but depend on a supporting frame and purlins for strength, whereas a concrete slab acts as a self‑supporting structural element.

3. Are noise levels during rain significantly different between concrete and metal roofing?

Concrete roof slabs tend to muffle rain noise due to their mass and thermal mass, while metal roofs can sound louder during heavy rain unless insulation is added.

4. Does roofing choice affect building energy usage in hot climates?

Metal roofs with reflective coatings can reduce solar heat gain and lower cooling loads, while concrete slabs' thermal mass helps stabilise internal temperatures, both of which can improve energy performance when well-designed.

5. How long do quality metal roofs last compared to concrete slab roofs under normal conditions?

With proper coatings and maintenance, metal roofs can last 40–70 years, and well‑designed concrete slab roofs typically exceed 50 years of service, with lifespan influenced by local climate and maintenance.