Essential Steel Transport Security Practices for Construction Projects

Steel rarely causes problems when it's ordered. The trouble starts when it's on the road. Delayed trucks, damaged material, missing quantities, or last-minute substitutions can stall an entire site. Labour sits idle. Schedules slip.

What looked like a simple delivery turns into a chain of follow-ups and firefighting. Steel transport security is about preventing those moments before they happen. When movement from supplier to site is planned, protected, and monitored, projects stay on track.

This blog breaks down the practical steps and sourcing practices that help contractors and project teams reduce transport risks, protect material quality, and keep construction moving without unpleasant surprises.

Key Takeaways

-

Steel transport security directly impacts project timelines. Delays, damage, or wrong dispatches quickly translate into site stoppages and rework.

-

Most transport risks can be controlled before dispatch. Clear specifications, proper documentation, and secure loading prevent common failures.

-

Road-based steel movement increases exposure to delays and damage. This makes planning, tracking, and delivery coordination critical for South India projects.

-

On-site receiving checks protects against hidden losses. Early inspection, safe unloading, and quantity verification stop small issues from escalating.

-

Structured sourcing improves transport reliability. Fewer handoffs, confirmed pricing, and planned deliveries reduce uncertainty during steel movement.

What Is Steel Transport Security for Construction Projects

Steel transport security refers to the set of controls used to ensure steel moves from the supplier to the construction site without loss, damage, substitution, or delay.

For contractors and project managers, this is less about transport vehicles and more about protecting project timelines, material quality, and cost certainty during transit.

In practical terms, steel transport security covers:

-

Correct material being dispatched (grade, size, brand as ordered)

-

Safe loading and fastening to prevent bending or surface damage

-

Protection against theft, tampering, or unauthorised unloading

-

Weather protection to avoid corrosion during transit

-

Predictable delivery timelines that align with site schedules

Steel transport security differs from general freight logistics. Steel is high-value, heavy, and difficult to replace quickly. A single transport issue can disrupt multiple activities on site.

Unlike general cargo, steel transport security must account for:

-

Grade sensitivity (especially TMT bars and structural sections)

-

Bulk volumes moved in a single consignment

-

Just-in-time delivery dependencies common in urban projects across Andhra Pradesh, Telangana, and Karnataka

-

Limited buffer stock at active construction sites

This is why steel transport security is treated as a core part of procurement planning, not a last-mile concern.

Steel transport security ensures the right steel reaches the site, in the right condition, at the right time, without disrupting construction schedules.

Once steel transport security is defined, the next step is to understand why gaps in this area create real on-site consequences for construction projects.

Why Steel Transport Risks Matter for Construction Projects

Steel transport risk isn't uncommon, given India's road-dependent freight system. In India, most freight movement is road-based, which increases exposure to theft, route disruptions, and handling-related damage.

Government sources commonly cite roads' dominant role in freight transport; for example, MoRTH notes 60% of freight traffic moves by road, and NITI Aayog/PIB references put road share around 70%.

For construction teams in Andhra Pradesh, Telangana, and Karnataka, that matters because steel is often delivered by road from mills/stockyards to city sites (Hyderabad, Bengaluru, Vijayawada) where:

-

Unloading space is tight,

-

Deliveries are time-slotted,

-

and crews depend on the truck arriving within the promised window.

How Transit Issues Become Site-level Problems

Steel transport risks first show up as time loss, then as money loss. Here's how common transport failures translate into project impact:

-

Delay in truck arrival → concreting schedules shift, shuttering cycles break, labour sits idle

-

Short supply / missing bundles → emergency sourcing at higher rates, re-planning bar bending schedules

-

Damage (bending, edge damage, surface wear) → rejection at site or forced use with extra cutting/wastage

-

Rust exposure during rain/poor covering → cleaning time, possible rejection depending on site QC rules

-

Wrong grade / wrong section dispatched → stoppage until corrected materials arrive, increased follow-ups

This is why steel transport security is not "extra caution." It's timeline protection. Additionally, transport crime and in-transit risk are real, not theoretical

A large share of theft incidents occurs while goods are in transit (not only at yards). For example, a 2025 cargo theft trends report notes that a significant portion of thefts occurs in transit (41% in one global dataset).

You don't need to assume every route is unsafe. But for high-value loads like steel, it's smart to treat transport as a controlled process with checks, not a black box.

Also Read: Steel Purchase Online Fraud: A Safety Guide for Contractors

Knowing the risks is only useful if it leads to prevention. Let's explore strategies to control the most common failure points in steel movement.

Core Practices for Steel Transport Security in Construction

Steel transport security works best when it's treated as a process, not a last-mile activity. The practices below focus on controlling the high-risk points in steel movement, from pre-dispatch checks to unloading readiness.

They're designed to help contractors, fabricators, and project teams reduce uncertainty, protect material quality, and keep deliveries aligned with construction schedules.

1. Pre-Transport Preparation & Documentation

Before dispatch, lock down three things: specs, proof, and accountability.

Pre-dispatch checklist (buyer-side):

-

Confirm the order line by line: grade, dia/size, length, bundle count, total weight, delivery address, and unloading slot.

-

Match documents to material: ensure invoices, delivery challans and packing lists reflect the exact items being dispatched (helps prevent shortages and disputes at receiving).

-

Capture dispatch proof: vehicle number, dispatch time, and dispatch photos (bundles + tags) where possible.

-

Define acceptance checks in advance: what the site team will verify at arrival (quantity, condition, markings).

If your site uses GRN-based receiving, tight dispatch documentation prevents “received vs billed" mismatches that slow down billing and approvals.

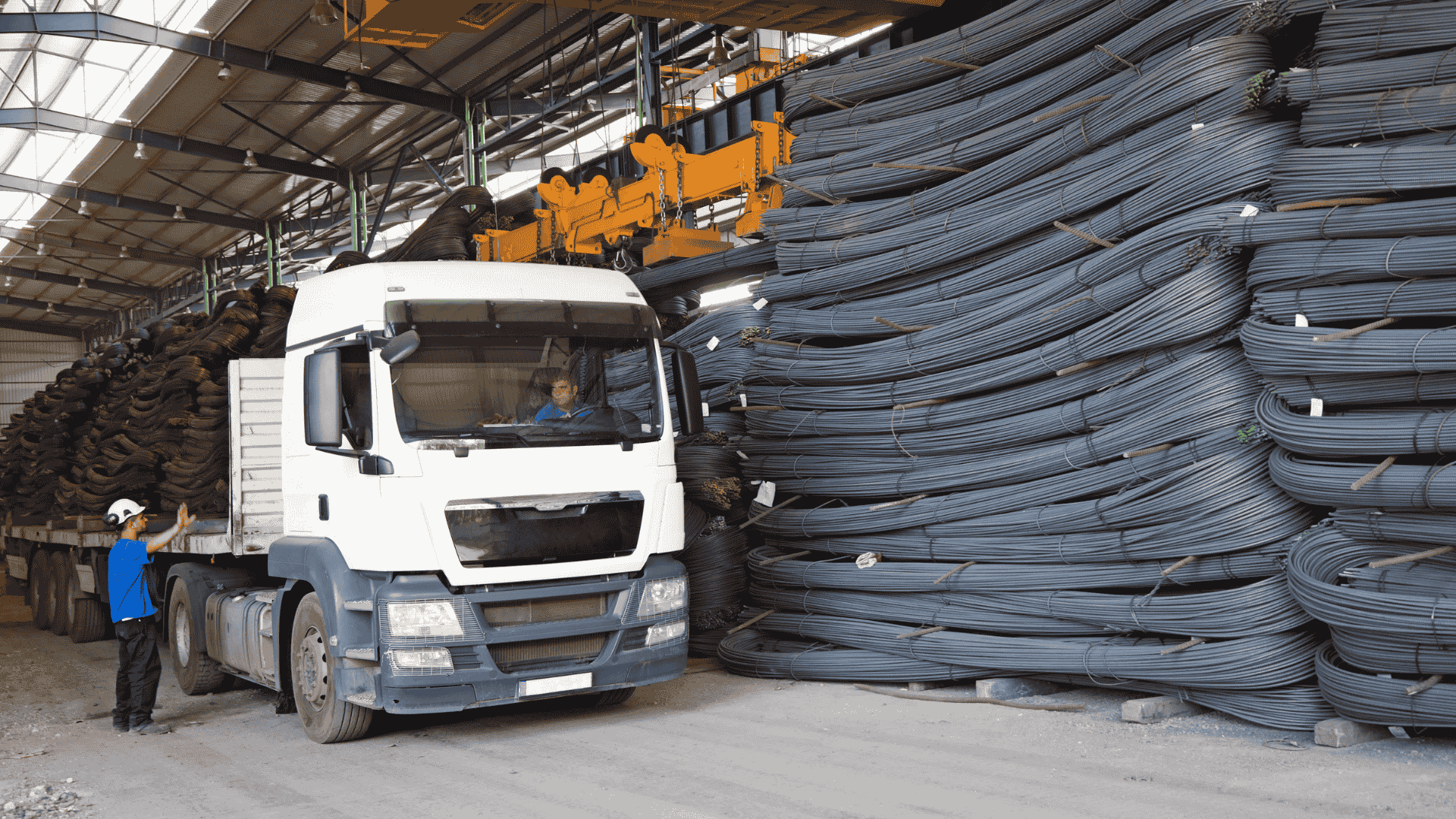

2. Secure Loading & Fastening Best Practices

Steel transport security starts with load restraint. Global road-freight rules treat "blocking, bracing, and tiedowns" as core controls because cargo movement is a major cause of damage and incidents.

What “secure" looks like in practice (for common steel loads):

-

Bundles and long sections (TMT, channels, beams):

Use dunnage/wooden blocks to keep bundles level and prevent metal-to-metal abrasion. Apply multiple tiedowns across the length to reduce lateral shift during braking/turns. Avoid overhang without proper support and marking.

-

Plates and flats:

Stack with separators; use edge protection under straps to prevent strap-cutting and edge damage.

-

Coils (where applicable in steel supply chains):

Commodity-specific securement rules exist because coils are high-risk loads if they tip or roll. One example is that US cargo securement rules apply special coil requirements for loads ≥ 2,268 kg (5,000 lb) per coil/group, emphasising tiedowns that prevent tipping forward/rearward or lateral movement.

You don't need to follow a foreign regulation word-for-word on Indian sites. The buyer takeaway is simple: the heavier and rounder the item, the more restraint engineering matters.

3. Weather Protection & Rust Prevention (Monsoon-Realistic)

On South India routes, monsoon exposure is a predictable risk. Moisture exposure is a key driver of steel deterioration, underscoring the need for prevention as a "system," not a last-minute fix.

Practical transport protections that matter:

-

Covering that stays put: use tarpaulins that are properly tied so wind doesn’t flap them open mid-route.

-

Keep bundles off the deck: dunnage reduces water pooling contact on the truck bed.

-

Minimise time parked in open yards: the longer the steel sits uncovered between dispatch and unloading, the higher the risk of surface rust.

-

Plan deliveries around rainfall windows when possible: even a few hours can determine whether the load needs on-site cleaning.

For receiving teams, treat “wet load + long transit” as a red-flag combo. It doesn't automatically mean rejection, but it should trigger closer inspection and faster unloading.

4. Real-Time Tracking and Visibility

Tracking is a steel transport security tool because it reduces three operational problems:

-

Unplanned idle time (labour/equipment waiting)

-

Unverified detours/stoppages

-

Late discovery of delays (no time to re-sequence work)

If you follow formal supply chain security systems, ISO's approach is "risk-based" and focuses on managing threats across the supply chain, including transport and disruptive incidents.

Visibility practices that work on real projects:

-

Confirm an ETA window at dispatch (not just “tomorrow").

-

Use milestone updates: dispatch confirmed → en route → near-site → arrived.

-

Keep a simple exception rule: if the truck is stationary beyond a set time, the coordinator checks why (traffic, breakdown, unloading queue).

This is less about fancy tech and more about keeping site plan procurement predictable.

Even well-planned transport can fail at the site level. Some delivery-stage checks are essential as well to ensure transport security remains in place until the material is safely received.

Practical Tips for Site Teams During Delivery

Most steel transport issues become expensive because they're discovered after unloading, cutting, or issuing material to teams. A tight receiving routine helps you catch problems early, document them cleanly, and keep procurement predictable across phased deliveries.

Below is a practical workflow your site engineer or stores team can run in 15–30 minutes per truck, depending on load size.

1) Before the Truck Enters

Assign one responsible receiver (the name on the GRN) and one witness from the contractor team. Keep space cleared for safe unloading and staging (avoid unloading into active movement zones).

Confirm the availability of unloading equipment (crane/forklift, slings, hooks) and their capacity.

2) At the Gate

Match paperwork first. It prevents "we unloaded it, now what?" disputes.

Document checks (must-do):

-

Delivery challan/invoice / e-way bill (where applicable)

-

Vehicle number + driver details recorded

-

Item list matches: grade, dia/size, length, quantity, bundle count

-

If your site uses GRN: create a pre-GRN entry with expected quantities and specs

This aligns with supply chain security best practice: identity/records verification before cargo is released/received.

3) On the Truck

Do a fast visual scan while the load is still secured:

-

Strap integrity: any cut straps, loose bands, broken seals (if used)

-

Signs of shifting: bent edges, deformed bundles, uneven stacking

-

Water exposure: pooled water, wet tarpaulin, rust staining on contact points

-

Bundle tagging/markings visible (helps avoid mix-ups during unloading)

Tip for phased projects: Photograph the load from 2–3 angles before unloading.

It's a simple record if shortages or damage are discovered later.

4) Safe Unloading

Unloading is a high-risk, high-damage hotspot. Hoisting bundles by non-designed straps is considered “extremely dangerous” because straps can loosen or break, creating falling-object hazards.

Safe unloading do's:

-

Use rated slings and lifting points, not bundle strapping

-

Stand to the side while cutting straps and expect movement when the tension releases

-

Ensure bundles are blocked/secured on level ground before cutting final straps

-

Keep a no-standing zone under suspended loads

Don’ts:

-

Don't release all restraints at once

-

Don’t unload into mud/standing water (invites corrosion and handling slips)

5) Quantity Control

For bulk deliveries, shortages are usually discovered late because teams rely only on invoice weight.

Practical options (choose what your project supports):

-

Bundle count + tag verification (fastest)

-

Random bundle weighing (spot-check method)

-

Weighbridge record (best when available and agreed in advance)

The goal is not perfection on every truck. It's creating a repeatable routine that reduces disputes and surprises when reordering.

6) Storage Immediately After Unloading

If the material is staged poorly, transport security gains are lost at the site.

Follow these clear, practical storage directions:

-

Reinforcement bars should be stacked at least 150 mm above ground level during long storage.

-

Structural steel of different sizes/lengths should be stored separately to reduce cutting waste and mix-ups.

Site application (especially in coastal AP or monsoon conditions):

-

Use dunnage and keep steel off bare ground

-

Separate stacks by grade and diameter/section

-

Tag stacks clearly so bar-bending/fabrication teams don't pull the wrong material

Now, when steel movement needs to be reliable at scale, the sourcing and coordination model behind each delivery becomes just as important as on-site checks.

How SteelonCall Helps Reduce Steel Transport Risk in Construction Projects

SteelonCall is an online steel marketplace designed for construction and fabrication teams that need predictable and well-coordinated steel deliveries, not physical transport security services. When transport risks threaten site schedules, material quality, and cost control, SteelonCall’s platform and coordination model help reduce uncertainty across sourcing, dispatch planning, and documentation.

Here are key ways SteelonCall supports lower delivery risk:

-

Verified Supplier Network That Reduces Mismatch & Dispute Risk

SteelonCall works only with verified suppliers vetted for quality and compliance.

This reduces a common transport-related issue: steel arriving on site that differs from the order. -

Direct Manufacturer Access for Brand & Grade Assurance

SteelonCall enables sourcing from recognised manufacturers such as Vizag Steel and other major brands. This helps ensure material traceability at the dispatch stage and reduces the risk of brand or grade substitution.

-

Online Pricing Visibility That Prevents Dispatch Friction

SteelonCall is the only platform offering online live steel pricing, allowing buyers to share requirements and receive pricing digitally before dispatch. Clear, pre-confirmed pricing reduces last-minute renegotiations that often delay dispatches.

-

Bulk Order & Phased Delivery Support

-

Large construction projects rarely move steel in one trip. SteelonCall supports bulk quantities, phased dispatch planning, and repeat deliveries over multiple weeks. This improves transport coordination and reduces uncertainty across project timelines.

-

Coordinated Logistics from Dispatch to Site

SteelonCall manages end-to-end delivery coordination, reducing handling points and follow-ups. Centralised logistics oversight improves delivery predictability and accountability during transit.

SteelonCall's online marketplace model helps construction teams reduce delivery risk, protect material integrity, and keep projects moving without disruption.

Wrapping Up

Steel transport security plays a direct role in keeping construction projects on schedule and under control. By focusing on structured dispatch planning, secure loading, weather protection, clear documentation, and disciplined site receiving, contractors and project teams can significantly reduce delays, damage, and supply disputes.

SteelonCall supports secure steel movement through its online steel marketplace by combining verified suppliers, direct manufacturer access with Vizag Steel priority, online price visibility, and coordinated logistics across South India.

If you're planning bulk steel requirements for your projects, check the latest steel prices on SteelonCall and align your sourcing with delivery reliability and grade assurance from day one.

FAQs

1) How can I reduce the risk of steel theft during transit to the site?

Limit handoffs by sourcing from verified suppliers, confirm dispatch details in advance, and use tracked deliveries with fixed routes and delivery windows. Clear accountability reduces in-transit risks significantly.

2) What documents should I verify before accepting a steel delivery on site?

Always cross-check the delivery challan, invoice, vehicle number, and item-wise specifications against your order. This helps prevent shortages, incorrect grades, and post-delivery disputes.

3) Does bulk steel transport increase the risk of damage or delays?

Bulk transport increases risk only when dispatches are unplanned. With phased scheduling, proper load securing, and coordinated logistics, bulk movement is often more predictable than multiple small deliveries.

4) How does online price confirmation help with steel transport security?

When prices are confirmed digitally before dispatch, last-minute renegotiations and shipment changes are avoided. This reduces dispatch delays and ensures the material sent matches the approved material.

5) What should site teams do if steel arrives wet or partially rusted?

Inspect the extent of exposure immediately, document with photos, and segregate affected material. Minor surface rust can often be managed, but early identification prevents quality issues later in the project.