Hot Rolled And Cold Rolled Steel: Which One Is Better?

When planning large-scale fabrication or construction, misidentifying material properties can lead to significant structural failure and rework. Relying solely on the aesthetic difference between smooth and scaly steel surfaces is a common error made by many procurement teams.

This superficial choice causes problems later with welding integrity, dimensional fitment, and long-term cost. The true difference lies in the material’s mechanical properties, which directly impact how the steel behaves under stress and during critical fabrication stages.

Making an informed choice prevents costly job site corrections and ensures your project meets its design specifications.

This guide provides a precise breakdown of hot-rolled and cold-rolled steel across key engineering parameters, helping you make the correct sourcing decision. You will gain a technical understanding of tolerances, internal stress, and cost implications for your next project.

Key Takeaways

-

Use Hot Rolled (HR) steel for all large structural components, frames, and heavy equipment. Reserve Cold Rolled (CR) steel for precision parts, aesthetic surfaces, and products requiring tight fitment.

-

HR steel has loose tolerances (approx. ±2mm variation), making it unsuitable for components requiring exact alignment. CR steel maintains high precision with tight tolerances of approximately ±0.1mm.

-

HR steel's rough surface and mill scale add a substantial cost of 15-20% to finishing expenses, as it requires grit blasting before painting. CR steel is ready for immediate painting or coating.

-

The cold working process increases the yield strength of CR steel by 15-20% due to work hardening. HR steel retains superior ductility and forgiveness under impact.

-

CR steel retains internal stresses that cause springback when forming and may cause warping when cut or welded. HR steel is virtually stress-free and welds "like butter" with standard techniques.

-

The base price of CR steel is typically 20-30% higher than HR steel. Contractors must calculate the Total Cost of Ownership (TCO), factoring in the labour savings from CR's lack of surface prep.

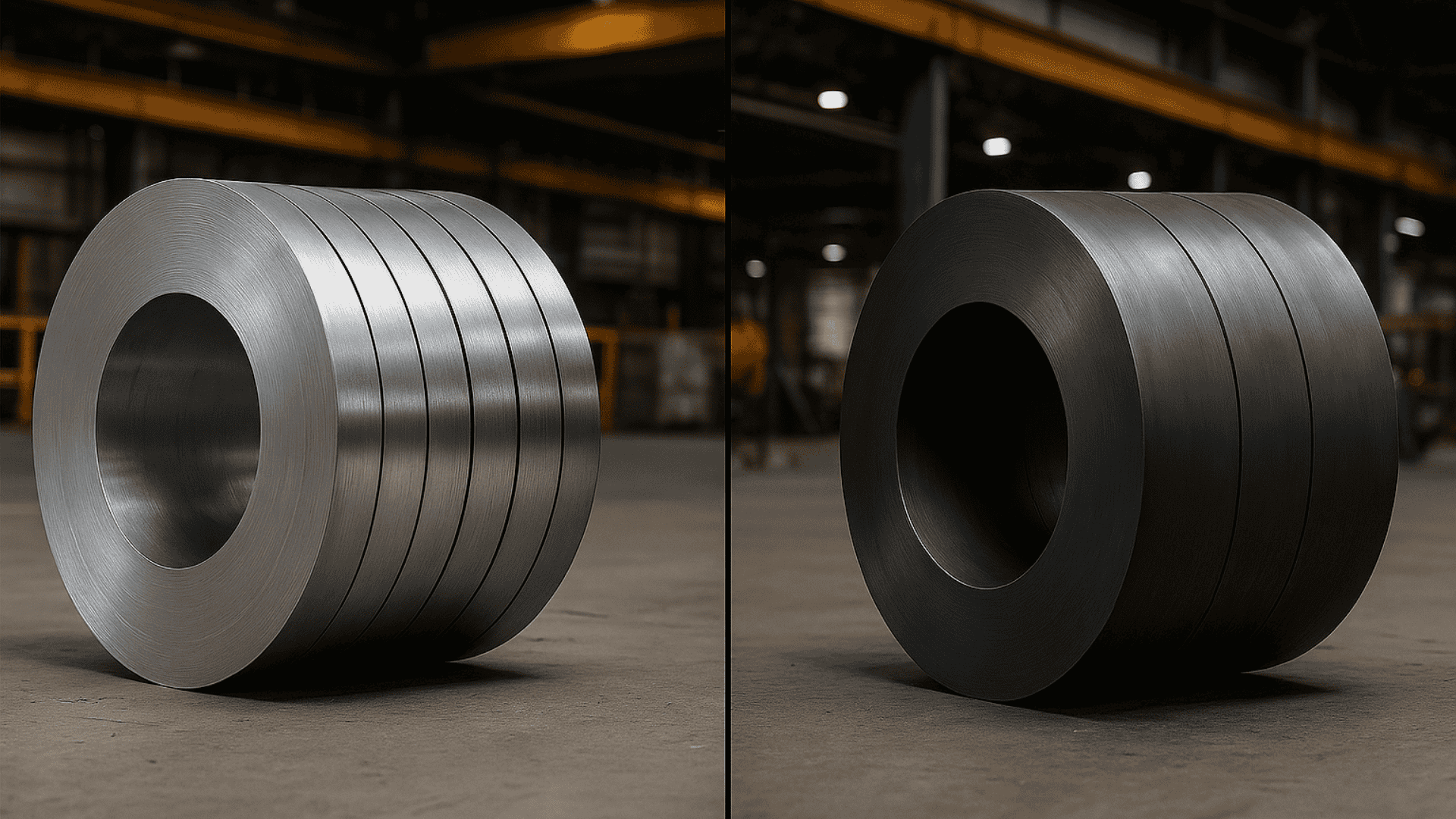

Understanding Hot-Rolled And Cold-Rolled Steel

The primary distinction between these two material types is the temperature at which the steel is processed, fundamentally altering its internal structure and performance characteristics.

Contractors and manufacturers must align this processing difference with the practical demands of their project. This prevents sourcing the wrong material and incurring additional, preventable fabrication costs on-site.

1. Hot Rolled Steel

Hot rolled (HR) steel is manufactured at temperatures exceeding 926 °C (the recrystallisation point), making the steel highly malleable and easy to form. The high temperature allows the material to be shaped into large structural components like beams and channels with minimal power.

Since the steel cools slowly after rolling, it is free of internal stresses, which benefits heavy construction work.

|

Where it works best |

Watchpoints |

|

Heavy Structures: Ideal for I-beams, H-beams, and columns in building frameworks and bridge construction. |

Surface Quality: The cooling process leaves a rough, scaly oxide layer (mill scale) that requires cleaning. |

|

Large Sections: Best for manufacturing heavy MS angles and channels where total section size is more critical than precision. |

Dimensional Variation: The non-uniform shrinkage during cooling results in wider dimensional tolerances and slightly rounded edges. |

|

Ductile Fabrication: Perfect for applications requiring extensive bending, deep drawing, or simple forming without the risk of cracking. |

Surface Preparation: Requires sandblasting or pickling to remove mill scale before welding or painting can begin. |

2. Cold Rolled Steel

Cold rolled (CR) steel is essentially hot rolled steel that undergoes further processing at room temperature, below the recrystallisation point. This refining process involves cold reduction mills or cold drawing, compressing the steel to achieve a far superior surface finish and precise dimensions.

This material is primarily used in applications demanding high aesthetic quality or tight component fitment.

|

Where it works best |

Watchpoints |

|

Precision Components: Essential for appliance housing, metal furniture, storage cabinets, and automotive body panels. |

Higher Cost: The additional processing steps required make CR steel significantly more expensive per tonne than HR steel. |

|

Aesthetics: Provides a smooth, clean, and shiny surface that accepts paint and coatings with excellent adhesion. |

Internal Stress: The cold working introduces significant internal stress, which may cause the material to warp when cut or welded. |

|

Tighter Tolerances: Used for all applications where dimensional accuracy and straightness are critical for final assembly. |

Reduced Ductility: The strain hardening makes the material harder and stronger, but it reduces its flexibility for deep forming operations. |

Also read:HR Sheet vs CR Sheet: Differences, Uses & Buying Guide

Understanding these core properties is essential, but the real test is knowing exactly when to apply each material based on project demands.

When Should You Choose Hot-Rolled Or Cold-Rolled Steel?

The selection of HR or CR steel moves beyond simple product features and becomes a strategic risk management decision for every project. Your choice must minimise on-site labour and align precisely with the structure's operational demands.

The ultimate decision should be driven by balancing the complexity of the required fabrication process against the longevity and finish quality of the end product.

Contractors can simplify the sourcing decision by evaluating their project based on three primary application categories:

1. Prioritising Structural Strength and Section Size

When the primary requirement is large-scale load bearing, Hot Rolled (HR) steel is the logical and economic choice. It maintains excellent ductility and is ideal for constructing heavy industrial frames, beams, and large diameter pipes.

This choice optimizes the material cost for non-aesthetic, foundational elements of a construction project.

2. Requiring High Dimensional Accuracy and Aesthetic Finish

For projects involving component assembly, machinery fabrication, or fine furniture, Cold Rolled (CR) steel is essential. Its consistent dimensions and superior flatness dramatically reduce fitment time during manufacturing processes.

Choosing HR here would require expensive machining to correct variances, eliminating any initial cost savings.

3. Minimizing Post-Fabrication Labour

The decision here depends entirely on which labour cost you wish to minimise. If your project demands a high-quality, painted finish without a large surface preparation budget, CR steel saves costs immediately.

Conversely, if extensive site welding is unavoidable, HR steel's lack of internal stress makes the joining process far more straightforward and predictable.

Also read:How to Calculate Steel Quantity in Columns? Explained

Strategic application sets the stage; now you must precisely quantify the technical and financial distinctions that separate these two materials in fabrication.

Key Differences Between Hot Rolled and Cold Rolled Steel

Understanding these manufacturing processes goes beyond surface-level descriptions. The rolling method fundamentally alters steel's behavior in fabrication, impacting everything from your welding choices to paint costs.

Here's how these differences translate to real-world construction and manufacturing decisions:

1. Surface Finish: Rough Workhorse vs. Smooth Performer

Hot-rolled steel's characteristic blue-grey scale isn't just cosmetic - it's oxidation from 1200°C processing. This mill scale must be removed by grit blasting before painting, adding 15-20% to your finishing costs. Cold-rolled steel arrives with a ready-to-paint surface that accepts powder coating and plating without extensive preparation.

Practical implication: Choose hot rolled for structural elements where appearance doesn't matter. Specify cold rolled for visible applications like architectural features or consumer products.

2. Dimensional Precision: Framework vs. Fine Furniture

Hot rolling's ±2mm tolerance means beam depths vary more than a rupee coin's thickness. This works for structural frames where connections accommodate variation. Cold rolling's ±0.1mm precision maintains consistency thinner than a credit card across production runs.

Practical implication: Use hot rolled for building skeletons where fit-up adjustments are expected. Select cold-rolled for manufacturing jigs, furniture frames, or any application requiring interchangeable parts.

3. Strength Characteristics: Tough vs. Stiff

Cold working increases yield strength by 15-20% through molecular rearrangement. Think of hot-rolled steel as tough clay that bends under pressure, while cold-rolled rolled acts like a stiff spring that resists deformation but may fracture under extreme stress.

Practical implication: Specify cold rolled for applications where you need strength in thinner gauges. Choose hot rolled for components requiring impact resistance and forgiveness.

4. Fabrication Behavior: Forgiving vs. Precise

Hot-rolled steel's memory-free nature means it stays where you bend it. Cold-rolled steel's internal stresses create springback - you must over-bend by 2-3 degrees to achieve your target angle, complicating precision fabrication.

Practical implication: Hot rolled suits site fabrication with basic tools. Cold rolled requires experienced operators and calibrated equipment for consistent results.

5. Cost Analysis: Budget vs. Premium

The 20-30% price difference reflects cold rolling's additional processing stages. However, this gap narrows when you factor in hot-rolled steel's necessary descaling and surface preparation for quality finishes.

Practical implication: For painted structural work, calculate the total cost, including surface preparation. The apparent savings of hot-rolled steel may disappear after grit blasting and priming.

6. Application Sweet Spots

Hot rolled dominates where mass matters more than precision: building frames, truck chassis, and structural supports. Cold rolled excels where appearance and accuracy are paramount: electrical cabinets, automotive panels, and precision mechanisms.

Practical implication: Match the steel to your tolerance and finish requirements rather than defaulting to familiar choices.

7. Welding and Machining Response

Hot-rolled steel welds like butter with standard techniques. Cold-rolled steel may require pre-heating to approximately 150°C to prevent cracking in the heat-affected zone, adding complexity to your welding procedures.

Practical implication: Choose hot rolled for site welding with basic equipment. Select cold-rolled for factory environments with controlled welding stations.

Also read:Diameter of Steel Bars: Sizes, Pricing & Buying Guide

In summary:

|

Factor |

Hot Rolled Steel |

Cold Rolled Steel |

|

Surface Quality |

Rough, scaly finish requiring surface preparation |

Smooth, ready-for-finish surface |

|

Tolerance Range |

±1-2mm (structural grade) |

±0.1mm (precision grade) |

|

Yield Strength |

Standard strength levels |

15-20% higher due to work hardening |

|

Cost Premium |

Base price (reference point) |

20-30% additional cost |

|

Ideal Application |

Structural frames, heavy equipment |

Automotive bodies, appliances, furniture |

With a clear technical matrix, you can now systematically match these distinct material properties to their corresponding real-world industry uses.

Applications Of Hot And Cold Rolled Steel

The final application dictates the mandatory material properties, making the decision purely utilitarian rather than cost-driven. Contractors should categorise their steel needs into foundational structural use or precise component fabrication.

This systematic approach ensures the longevity of the entire assembly and avoids unnecessary structural risk in the finished product.

The primary applications are clearly segregated by the core material properties each project segment demands:

1. Foundational Frameworks and Heavy Load-Bearing

Hot-rolled steel is the foundation for all major structural segments, including large ISMB beams, channels, and heavy angle sections. Its flexibility and lower production cost make it ideal for framing industrial sheds and bridges in South India.

HR steel’s tough, ductile nature is crucial for supporting significant static and dynamic loads in high-traffic commercial buildings.

2. Component Manufacturing and High-Tolerance Assemblies

Cold-rolled steel dominates the precision Fabrication Steel segment, where surface quality is paramount. It is standard for manufacturing automotive components, small tubes, and high-tolerance office furniture like filing cabinets.

The clean surface reduces finishing time for items that require plating or an aesthetically perfect powder coat finish.

4. Utility and Non-Aesthetic Functional Uses

For utility applications like general piping, simple fencing, or tank storage, the material choice is largely determined by the required wall thickness and cost. HR steel is commonly used for heavy-duty storage tanks and larger diameter pipe sections.

CR steel is often chosen for smaller, high-pressure tubing where consistent wall thickness is critical for safety.

Also read:Planning Steel Purchase? Check 10 mm Rod Weight & Bars per Bundle

Matching material to application is only half the battle; the final challenge is navigating the fragmented market to procure verified materials efficiently.

Streamline Your Steel Sourcing With SteelOnCall

Sourcing the correct steel type presents challenges for fabricators and contractors. Inconsistent quality, unclear specifications, and supplier reliability issues often disrupt production schedules.

SteelonCall provides a reliable solution for your hot-rolled and cold-rolled steel requirements. Our platform connects you directly to verified manufacturers with guaranteed specifications.

-

Verified Quality Materials: We supply HR plates, CR sheets, and structural sections from certified manufacturers.

-

Direct Manufacturer Access: Source materials directly from trusted mills, ensuring authentic products with transparent pricing.

-

Wide Selection: Choose from various grades and sizes of both hot-rolled and cold-rolled steel products.

-

Reliable Regional Delivery: Our managed logistics ensure materials reach your fabrication unit in Andhra Pradesh, Telangana, or Karnataka on schedule.

This streamlined approach provides manufacturers with a dependable supply chain for all steel requirements.

Also read:12mm Steel Bar Length Chart: Check Vizag Steel 12mm Rod Details

Conclusion

Choosing between hot-rolled and cold-rolled steel ultimately requires balancing cost and required precision against mechanical performance. Use hot-rolled steel for load-bearing structures where ductility and economy are vital, such as main building frameworks and heavy sections.

Select Cold Rolled steel only for components demanding superior surface finish, tight dimensional accuracy, and higher localised strength, such as roofing sheets or machinery casings.

SteelOnCall simplifies this critical material sourcing decision by aggregating high-quality HR and CR inventory from verified manufacturers onto one transparent platform. We assure verifiable quality, clear pricing, and efficient logistics, helping you execute complex projects with total confidence.

Check our live prices today to secure the best bulk rates for your steel requirements.

FAQs

Q. Why does cold-rolled steel cost more than hot-rolled steel?

Cold-rolled steel requires extra processing steps, including cooling, annealing, and re-rolling at room temperature. This additional labour and specialised machinery input increases the manufacturing cost significantly compared to the simpler hot rolling process.

Q. Can I use hot-rolled steel for high-precision components?

No, hot-rolled steel is unsuitable for high-precision components due to its wide dimensional tolerances and unpredictable shrinkage after cooling. Precision manufacturing relies exclusively on cold-rolled steel for consistent and accurate fitment.

Q. How do I prevent cold-rolled steel from warping after cutting?

The warping is caused by the release of residual internal stresses trapped during the cold rolling process. You must specify a stress-relieving heat treatment for CR steel before it is cut or welded to minimise this risk.

Q. What does "mill scale" mean for a contractor?

Mill scale is the flaky, dark oxide layer found on hot-rolled steel surfaces. It acts as a poor base for paint and must be removed by grinding, sandblasting, or pickling before applying any protective coating.