Understanding Mild Steel Grades in Indian Standards

Steel is at the heart of many industries, yet selecting the right steel type can be a daunting task. With so many grades and specifications available, how do you know which one fits your project’s needs? Whether you're in construction, manufacturing, or fabrication, the stakes are high when it comes to material choice.

India’s steel demand is expected to grow at a CAGR of 7% to touch 190 Million Tonnes (MT) by 2030, reflecting its increasing importance in infrastructure development. As more projects increase, choosing the right steel becomes even more critical. A poor decision can result in delays, budget issues, or weak structures.

In this blog, we’ll explore the key types of steel used in construction and fabrication. We’ll discuss how to select the appropriate grade for your project, the differences between various steel types, such as TMT bars and MS pipes, and how to avoid common pitfalls in material selection.

Key Takeaways:

-

Steel grades determine strength, durability, and weldability, impacting project success.

-

IS 2062 classifies mild steel grades based on mechanical properties like yield and tensile strength.

-

Mild steel is widely used in construction, fabrication, and machinery due to its versatility.

-

Choosing the right steel grade depends on factors like load-bearing capacity, environmental conditions, and cost.

-

SteelOnCall offers a convenient way to access high-quality steel with real-time pricing and reliable delivery.

What Are The Steel Grades?

Steel grades represent the specific chemical composition and mechanical properties of steel. Understanding these grades is essential because each grade offers different strengths, hardness, flexibility, and corrosion resistance. The right choice of steel can make or break the success of your project, whether it’s in construction, manufacturing, or fabrication.

Structural & Construction Steel Standards

When working with construction steel, it’s essential to choose grades that meet the required strength and load-bearing capacity. Below is a table that outlines key IS codes relevant to steel used in construction, fabrication, and testing:

|

IS Code |

Title / Scope |

|

IS 2062 |

Hot Rolled Low, Medium and High Tensile Structural Steel |

|

IS 1786 |

High Strength Deformed Steel Bars and Wires for Concrete Reinforcement (TMT bars) |

|

IS 800 |

General Construction in Steel — Code of Practice |

|

IS 808 |

Dimensions for Hot Rolled Steel Sections |

|

IS 875 (Part 1–5) |

Design Loads for Buildings and Structures (Dead, Live, Wind, Snow, Seismic) |

|

IS 12778 |

Hot Rolled Parallel Flange Beams and Columns |

Now that we understand the standards and specifications governing steel materials, it's crucial to dive into why selecting the right steel grade is a fundamental aspect of construction projects.

Importance of Steel Grades in Construction

Choosing the wrong grade could lead to serious issues, such as structural failure or unnecessary costs. The grade determines how well the steel can withstand forces, pressure, temperature changes, and environmental conditions.

It is also crucial for welding, bending, and forming processes. As a result, the choice of steel grade directly impacts both the project’s cost and durability.

Here’s why steel grades are so critical:

-

Strength & Durability: Steel grades determine the tensile and yield strength of the material, ensuring it can withstand the intended load and stress.

-

Corrosion Resistance: Certain grades offer better resistance to rust and environmental factors, making them ideal for outdoor or high-moisture environments.

-

Weldability & Formability: Some grades are easier to weld or form, while others might require more advanced techniques or higher heat.

-

Cost Efficiency: Selecting a steel grade that meets your project’s specific needs without over-specifying can help manage your budget effectively.

-

Standards Compliance: Different industries may require specific grades to meet local or international standards for safety and quality.

After understanding what steel grades represent, it’s crucial to recognise how these variations impact different applications.

Types of Steel Commonly Used in Construction

In construction, various types of steel are chosen to meet specific structural, durability, and fabrication needs based on the project requirements. The choice of steel type has a direct impact on the overall strength, safety, and longevity of the building. Whether you’re working on a residential, commercial, or industrial project, knowing the different steel types will help you choose the right material for your needs.

Each steel type has specific properties that make it suitable for particular applications, from reinforcing concrete to framing heavy structures. Selecting the proper steel type can save time, reduce costs, and enhance the project's overall integrity. Here are the most commonly used types of steel in construction:

-

Mild Steel (Low Carbon Steel): Mild steel is affordable and easy to work with, making it ideal for general construction and structural applications. It has a low carbon content, which allows for better ductility and welding properties.

-

TMT Bars: Thermo-Mechanically Treated (TMT) bars are commonly used for reinforcing concrete. These bars offer high tensile strength and excellent flexibility, which are crucial for earthquake-resistant structures. Grades like Fe500D and Fe550D are popular due to their superior strength.

-

Carbon Steel: Carbon steel is commonly used in construction due to its strength and ability to support heavy loads, especially in reinforcing bars and structural beams.

-

Alloy Steel: Alloy steel is used when specific properties, such as high resistance to wear, corrosion, or heat, are required. It is often used for machinery and heavy-duty applications in construction.

-

Stainless Steel: Stainless steel is well-known for its excellent resistance to corrosion, making it a popular choice for projects exposed to moisture or requiring aesthetic design, like handrails and kitchen fixtures.

-

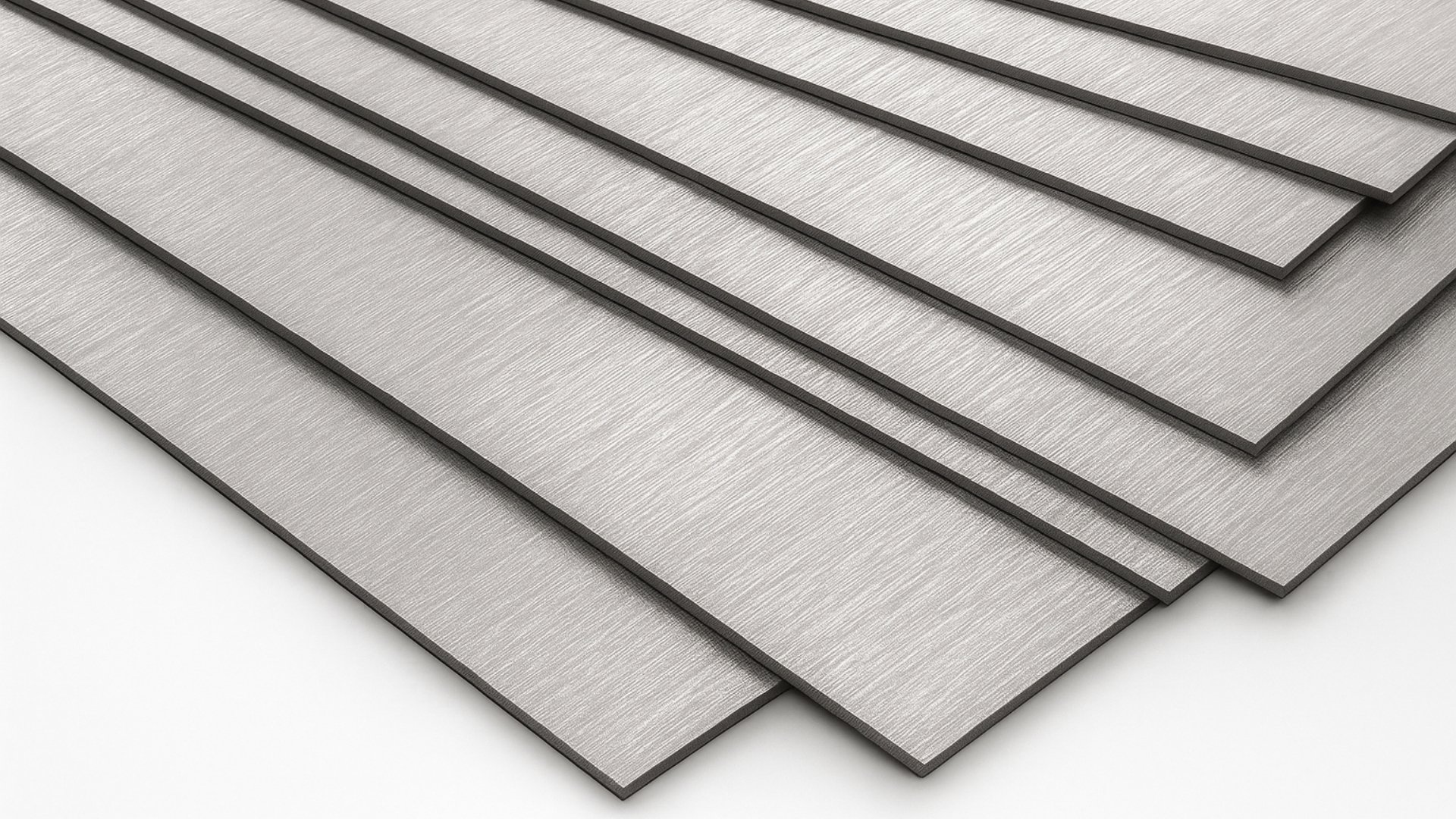

MS Plates and Flats: Mild steel plates and flats are versatile, flat steel products used in fabrication for structural components, flooring, and vehicle manufacturing.

-

HR (Hot Rolled) Sheets: Hot-rolled steel sheets are used in structural applications due to their affordability and strength. These sheets are ideal for projects that require large, flat surfaces.

-

CR (Cold Rolled) Sheets: Cold-rolled steel is stronger and has a smoother finish compared to hot-rolled steel. It's typically used in situations where precise dimensions are essential.

With a clearer understanding of steel grades, we can look at the various types of steel available for construction.

Mild Steel Grades Classification in Indian Standards

Steel grades under IS 1786 and IS 2062 are designed for different construction and engineering applications. These grades are defined by their yield strength, tensile strength, and elongation, ensuring they meet the specific needs of a project.

IS 1786 grades are mainly used in reinforced cement concrete (RCC) structures, such as beams and columns. IS 2062 grades are used for general engineering and heavy-duty fabrication in industries.

Common Mild Steel Grades:

|

Standard |

Grade |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

|

IS 1786 |

≥500 |

≥545 |

≥12 |

|

|

IS 1786 |

≥550 |

≥585 |

≥10 |

|

|

IS 1786 |

≥600 |

≥600 |

≥8 |

|

|

IS 2062 |

E250 |

≥250 |

~410 |

≥23 |

|

IS 2062 |

E350 |

≥350 |

~490 |

≥22 |

|

IS 2062 |

E450 |

≥450 |

~570 |

≥20 |

Knowing which grades of mild steel are best for different uses will help determine how it can be applied.

Applications of Mild Steel in Construction and Fabrication

Mild steel is widely used in construction and fabrication due to its affordability, flexibility, and ease of working with, making it perfect for many projects. Mild steel is commonly used in applications that require moderate strength and durability, offering an excellent balance between cost and performance.

In both construction and fabrication, mild steel plays a key role in structural integrity and machine manufacturing. Here are some typical applications of mild steel:

-

Structural Frames: Mild steel is commonly used in building frames, including beams, columns, and girders, due to its ability to support heavy loads in structures like buildings and bridges.

-

Reinforced Concrete: Used in combination with concrete, mild steel provides reinforcement that enhances the material’s tensile strength. TMT bars, such as Fe500D and Fe550D, are commonly used for this purpose.

-

Machinery Parts: Mild steel is often used for manufacturing gears, shafts, and machine components. It’s especially valuable when a material needs to withstand heavy loads without breaking.

-

Pipes and Tubes: Mild steel pipes are widely used in plumbing, gas lines, and industries requiring strong, durable piping that resists wear and tear over time.

-

Steel Plates and Sheets: Mild steel plates and sheets are used in various industries for making industrial equipment, automotive parts, and structural components. They are easy to fabricate and weld.

-

Fabrication of Structural Components: Mild steel is widely used in the fabrication of steel components for construction, such as staircases, handrails, and frames for machinery.

-

Automobile Manufacturing: It is often used in vehicle manufacturing for making parts like frames, chassis, and panels due to its affordability and workability.

-

Fencing and Gates: Mild steel is also used for manufacturing gates and fences in both residential and industrial settings. It offers durability at a reasonable cost.

Now that we have explored the different types and applications, the next step is ensuring that the steel grade aligns with your specific project needs.

How to Choose the Right Steel Grade for Your Project?

Selecting the right steel grade for your project ensures it meets safety standards, lasts longer, and stays within budget without compromising performance. The right steel grade will meet the load-bearing requirements, resist environmental factors, and support the overall functionality of your structure or product.

A wrong choice of steel grade can lead to poor structural performance, increased maintenance costs, or even material failure. By carefully considering your project's specific needs, you can choose the steel grade that best fits the requirements and ensures success.

Here are the key factors to consider when choosing the right steel grade:

-

Load-Bearing Capacity: Choose a grade with the appropriate tensile and yield strength to support the weight and stress that the material will endure.

-

Environmental Conditions: If your project is exposed to moisture, chemicals, or extreme temperatures, select a steel grade that offers the necessary corrosion resistance.

-

Welding and Fabrication Needs: Some grades are easier to weld or shape, which can reduce fabrication time and cost. Ensure the steel grade matches the required fabrication methods.

-

Strength vs. Ductility: A balance between strength and flexibility is crucial, especially for projects subjected to vibrations or movement. Select a grade that offers the right balance for your needs.

-

Corrosion Resistance: Consider environmental exposure, such as outdoor applications or coastal areas, where corrosion resistance is a critical factor in selecting steel.

-

Cost Considerations: While high-strength grades may be necessary for specific projects, balancing material costs with the required performance can help optimise your project budget.

Once you’ve identified your ideal steel grade, sourcing it efficiently is equally important. SteelOnCall offers easy access to a wide variety of steel products designed to meet your needs, with on-time delivery and guaranteed quality.

Why SteelOnCall is the Right Choice for Your Steel Needs?

When selecting steel for your construction or fabrication projects, reliability, timely delivery, and cost management are key factors. SteelOnCall offers a reliable platform to source a wide variety of steel products, ensuring you get materials tailored to your project’s needs.

From project planning to material delivery, SteelOnCall simplifies sourcing. You gain access to top-quality steel, competitive prices, and a hassle-free buying experience.

Here’s why you should consider purchasing your steel from SteelOnCall:

-

Comprehensive Range of Steel Products: SteelOnCall offers a wide selection of steel types, including MS rounds, MS plates, and popular TMT bars such as Fe500D and Fe550D.

-

Real-Time Price Transparency: With live price updates, you can better manage your steel purchases and avoid unexpected fluctuations that might affect your budget.

-

Cost Savings with Bulk Purchases: For large-scale projects, you can achieve significant cost savings through bulk purchase discounts, making it easier to manage large quantities of steel.

-

Reliable and Timely Delivery: SteelOnCall ensures that your steel materials are delivered on time, keeping your project schedule intact and avoiding unnecessary delays.

-

Guaranteed Quality and Certification: All steel products come with certification that confirms they meet the required industry standards, providing peace of mind and reliability.

By choosing SteelOnCall, you simplify your procurement process, ensuring that your steel is of high quality, delivered on time, and fits within your project budget.

Conclusion

Choosing the right steel for your construction or fabrication project is crucial to ensuring its success. SteelOnCall offers a wide variety of steel products, real-time pricing, and reliable delivery, making your procurement process cost-effective and straightforward. With high-quality materials and bulk purchase discounts, it’s the smart choice for both large and small-scale projects.

FAQs

1. What is the difference between mild steel and TMT bars in construction?

Mild steel is commonly used in construction for general structural work, offering good ductility and weldability. On the other hand, TMT bars are designed specifically for reinforced concrete due to their superior tensile strength and flexibility, making them ideal for earthquake-resistant buildings.

2. What does IS 2062 specify about mild steel grades?

IS 2062 outlines the classification of mild steel grades based on their yield strength, tensile strength, and elongation properties. It helps determine the suitability of steel for different structural and engineering applications.

3. How does carbon content affect mild steel?

The amount of carbon in mild steel determines its strength and ductility. Lower carbon content offers better flexibility and weldability, while higher carbon content increases strength but reduces malleability and ease of welding.

4. Why is corrosion resistance important when selecting steel?

Steel exposed to harsh weather conditions or chemicals can degrade over time. Some steel grades, especially those with lower carbon content, are more resistant to rust, making them ideal for outdoor or moisture-prone applications.

5. What should I consider when selecting the right steel grade for a project?

Consider the weight and stress the material will endure, as well as environmental factors like exposure to moisture or chemicals. Additionally, the required ease of welding and fabrication methods will help guide your decision on the appropriate grade.