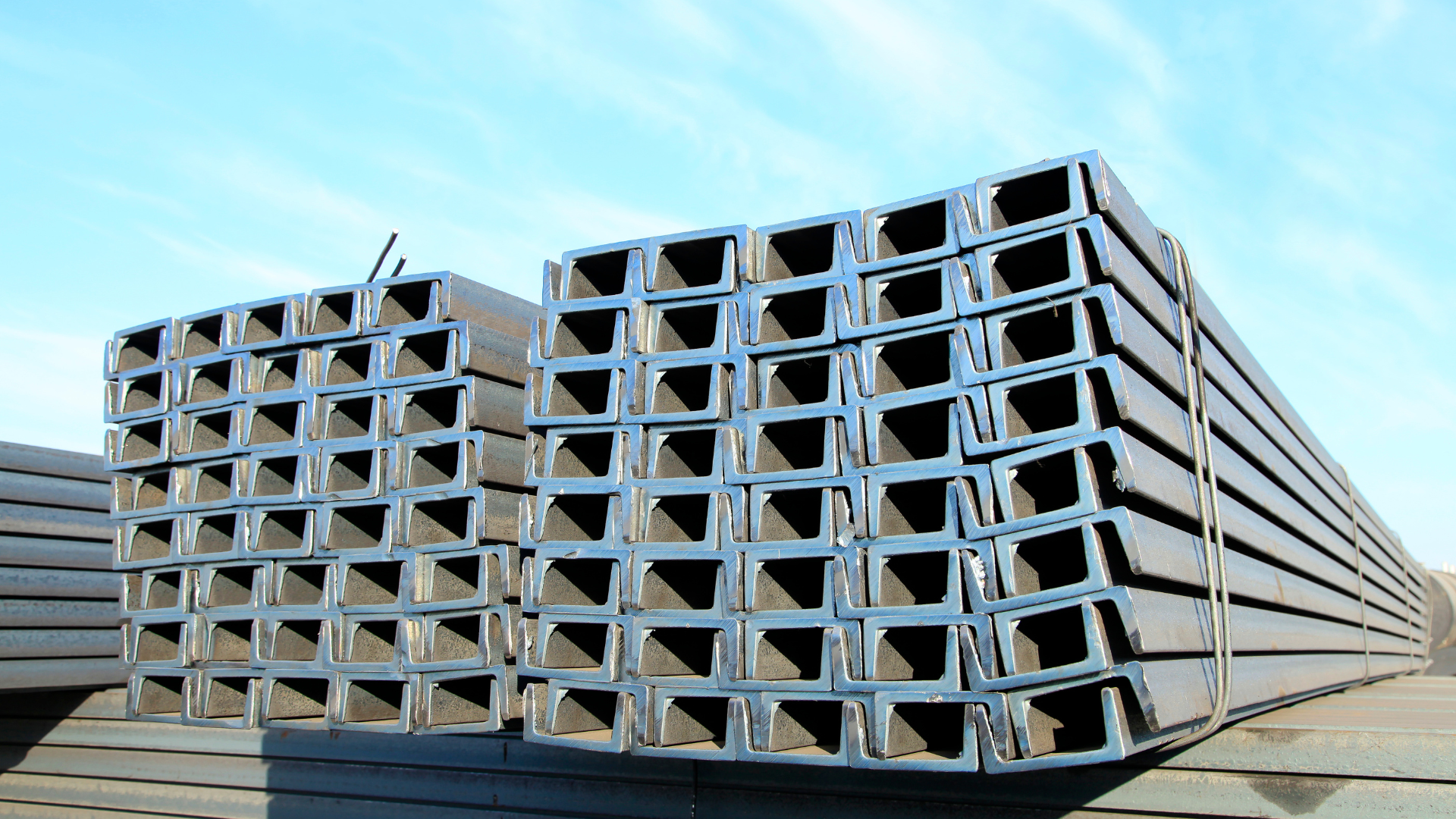

MS Channels for Facade Systems: Best Types, Sizing Rules & On-Site Checklist

The facade is the most unforgiving stage of a project; everything becomes visible. If the wrong MS channels are sourced or delivery is late, finishing work stalls, alignment suffers, and rework suddenly becomes everyone’s problem. Even a minor deviation or substitution at this stage can create cracks, uneven cladding, and safety liabilities that stay on the building for years.

This guide helps you eliminate those risks early by understanding which MS channels suit different façade systems, how sizing decisions influence structural stability, and the checks that keep installation moving without delays.

With the right approach, facade execution becomes cleaner, faster, and far more predictable, exactly what every contractor wants when deadlines tighten.

Before we dive in

-

MS channels are essential for façade alignment, load handling, and long-term stability, especially for glass and ACP systems.

-

Choosing the right ISMC size and corrosion protection prevents visible defects like misalignment, cracks, and rust stains on elevation surfaces.

-

Delivery and sourcing delays directly impact scaffold rentals, installation speed, and finishing deadlines, accuracy in procurement matters.

-

Verified, traceable steel ensures section thickness and straightness comply with design tolerances, reducing on-site adjustments and rework.

-

Coordinated, bulk delivery through digital platforms like SteelonCall keeps facade progress continuous and complaint-free.

Why Facade Steel Selection Impacts Project Success

Selecting the right MS channels is critical during the façade phase because this is when structural quality becomes fully visible. Any error in steel sizing, strength, or delivery timing directly impacts installation speed, alignment, and the final handover quality of the building.

How wrong steel selection affects façade outcomes:

-

Poor stiffness → panel misalignment, visible joint gaps

-

Low corrosion resistance → leaks, rust stains, maintenance failures

-

Size mismatch → cladding/ACP fixing difficulties

-

Site delays → scaffold time extensions + finishing rework

-

Subcontractor coordination issues → blame gaps & cost disputes

When MS channels are correctly selected and delivered as scheduled, facade installation becomes faster, cleaner, and complaint-free, protecting both budgets and deadlines.

Benefits of Using MS Channels for Facade Structures

MS channels are widely used in facade framing because they provide the strength and precision needed for clean architectural finishes. Their straight, uniform profile supports fast installation, reduces rework, and helps cladding teams maintain alignment across large elevations.

Here’s why they are preferred for façade execution:

-

High Strength in Slim Profiles: Supports glass, ACP, louvers, and signage without bulky structural members, improving aesthetics and space efficiency.

-

Accurate Alignment for Finishing Works: Straight geometry ensures clean edges, consistent panel joints, and reduced visible flaws during installation.

-

Faster Fabrication & Welding on Site: Easy to drill, cut, and bolt, keeping façade progress steady even with tight schedules.

-

Reliable Support for Wind Loads & Vibration: Maintains stability for high-rise facades and external fixtures exposed to strong wind pressures.

-

Cost-Effective vs. Heavier Sections: Suitable for façade loads without overspending on beams or heavier structural steel.

-

Multiple Sizes Available for Design Flexibility: Engineers can match section depth to span requirements, reducing unnecessary steel weight and cost.

Suggested read: MS Steel vs SS Steel: Key Differences That Matter in 2025

Types of MS Channels Used in Facade Construction

Different facade systems require different steel profiles depending on load, span, and installation detailing. The right MS channel type helps maintain alignment, carry cladding weight, and handle wind pressure without visible deformation.

Below are the most commonly used MS channels for façade execution.

1. ISMC C-Channels (Indian Standard Medium Channel)

These are the primary load-carrying members for façade frames because they provide high stiffness and good connection strength.

Applications:

-

Main frame for glass & ACP facades

-

Horizontal/vertical supports behind elevation panels

-

Signage and façade equipment brackets

2. U-Channels

Best suited for edge support where lightweight finishing elements need accurate alignment. They make installation easier in perimeter zones.

Applications:

-

Window and door surround reinforcement

-

Cladding panel edge trims

-

Holding tracks for sliding glass

3. Perforated Channels

Allow easy routing of cables, drainage pipes, or ventilation behind façade systems. Lightweight yet strong for secondary frame supports.

Applications:

-

Ventilated facade sub-framing

-

Cable trays for facade lighting

-

Service brackets behind cladding

4. Cold-Formed Custom Channels

Designed to meet architectural shapes or concealed support zones. Used when standard ISMC/U-channel sizes won’t match depth or visibility requirements.

Applications:

-

Curved façade supports

-

Slim-profile frames for modern elevation designs

-

Decorative or exposed steel elements

5. Galvanized Channels (Hot-Dip or Factory-Coated)

Used in high-exposure external facades to prevent rust, staining, and long-term maintenance failures.

Applications:

-

Coastal zone building facades

-

Rain screen cladding systems

-

Facade access frames and maintenance rails

Facade Use Cases, Where MS Channels Fit Best

Facade work needs steel that keeps alignment precise while supporting cladding weight and wind loads. MS channels provide a reliable sub-frame that helps finishing teams work faster and deliver a clean architectural look without rework.

Here’s where MS channels are most effective in facade construction:

|

Facade Component |

Why MS Channels Are Used |

On-Site Benefit |

|

Glass & ACP framing |

High stiffness in slim depth |

Clean, straight panel joints |

|

Louvers & shading fins |

Slim, strong support for cantilever elements |

Modern aesthetic without bulky steel |

|

Signage structure installation |

Handles vibration & fixture loads |

Safer installation for heavy letters/lights |

|

Window & door surround reinforcement |

Prevents edge bending/racking |

Crack-free finishing and proper sealing |

|

Service & cable support behind facades |

Routing + easy fastening |

Faster MEP integration |

|

Maintenance access frames for high-rise facades |

Strong load-bearing and durable |

Worker-safe façade maintenance |

|

Cladding brackets for irregular building edges |

Flexible cutting/welding onsite |

Easy adjustments during installation |

This table helps site teams quickly identify the right MS channel application before ordering.

How to Choose the Right MS Channel Size for Facade Works

Choosing the correct ISMC size is crucial because façade elements rely on slim sections that must handle wind loads and cladding weight without deflection. A few practical checks help ensure the steel frame remains stable and visually aligned throughout installation.

Here’s a simple selection approach contractors follow:

-

Match Size to Span Length: Longer horizontal members typically need deeper channels (e.g., ISMC 100+ for multi-meter spans) to control bending and joint gaps.

-

Consider Load from Cladding Material: Heavy glass or stone cladding requires stronger channels than lightweight ACP or louvers.

-

Check Drilling & Welding Access: Section thickness must allow proper welding penetration and bolt fixings for clean installation on site.

-

Plan for External Exposure: Facades facing rain or coastal wind should use galvanized or coated channels to prevent rust stains and corrosion damage.

-

Follow Structural Drawing Requirements: Always confirm with the engineer’s schedule; small variations in profile thickness can lead to major finishing issues.

A correctly selected channel ensures clean joints, reduced rework, and a faster facade execution cycle.

Suggested: Steel Test on Site: 10 Essential Tests for TMT Bar Quality Assurance

Facade Procurement Checklist for Contractors

Facade steel orders affect the final look of the building, which is why procurement needs zero guesswork. This quick checklist helps ensure the MS channels delivered are exactly what the finishing team needs to keep installation moving without delays.

|

Procurement Check |

Why It Matters |

Quick Action |

|

ISMC size as per the structural drawing |

Prevents bending & misalignment |

Verify mill test reports + physical tape check |

|

Section thickness tolerance |

Stops visible deflection after cladding |

Confirm manufacturer's specification sheet |

|

Coating requirement (paint/galvanized) |

Prevents rust stains on the facade |

Align the finish with the exposure condition |

|

Brand & batch confirmation |

Avoids low-grade substitutions |

Ensure supplier tags on each bundle |

|

Delivery timing vs scaffold readiness |

Saves rental & labour cost |

Lock the delivery window before ordering |

|

Wind load compliance (for high-rise) |

Ensures façade safety & stability |

Reconfirm with the design team for edge zones |

|

Access for bolting & welding |

Avoids site improvisation |

Check drillability + welding gap |

|

Bundle traceability during installation |

Ensures QA accountability |

Keep label records floor-wise |

Use this checklist before every facade steel order to avoid delays, disputes, and rework.

Common Mistakes in Sourcing Facade Channels, and How to Avoid Them

Small procurement errors during facade planning often turn into major finishing delays. These mistakes are completely avoidable when the right checks are followed from the beginning.

Here are the issues contractors most often face, and how to prevent them:

-

Ordering Undersized Channels: Results in deflection, panel misalignment, and visible joint gaps.

Fix: Always verify span-to-depth suitability before approval. -

Accepting Alternate/Unverified Brands: Low-quality steel leads to welding issues and inconsistent thickness.

Fix: Stick to verified suppliers with batch traceability. -

Late Ordering After Finishing Crew Mobilizes: Scaffold extensions, idle labor, and cladding delays hurt cost and schedule.

Fix: Align material arrival with facade work start date. -

Ignoring Corrosion Protection Needs: Outdoor channels rust quickly, causing staining and sealing failures.

Fix: Plan galvanizing/primer upfront based on weather exposure. -

Improper Handling at Site: Bending of edges during unloading creates alignment issues.

Fix: Use support slings and designated stacking zones.

By preventing these common pitfalls, facade execution remains predictable, protecting both deadlines and visual finish quality.

Conclusion

Facade execution demands complete precision because any misalignment or structural weakness becomes permanently visible once cladding goes up. Most delays at this stage come from steel supply gaps, size mismatches, or onsite adjustments that could have been prevented with better material planning.

Reliable sourcing of MS channels ensures dimensional accuracy, cleaner installation, and continuous progress during the finishing cycle, avoiding costly scaffold extensions and rework. When every visible element depends on the steel frame behind it, consistency in supply becomes just as important as engineering design.

SteelonCall supports facade contractors with verified structural steel, bulk delivery coordination, and live location-based pricing, helping site teams keep installation fast, aligned, and risk-free. Check live MS Channel pricing & availability here.

FAQs

1. Which MS channel sizes are commonly used for building facades?

Mild steel channels in the 75–150 mm range are most frequently used for façade frames, support grids, and cladding alignment. Final sizing depends on wind load, facade height, and bracket spacing defined in structural drawings.

2. Are MS channels suitable for façade work in coastal or high-humidity zones?

Yes, but only with proper surface protection like hot-dip galvanizing or approved paint systems. This prevents corrosion and protects the frame behind the cladding.

3. Can MS channels handle the load of glass façades?

They can, when selected based on correct load design and spacing. For heavy glazing systems, engineers may shift to ISMC 100+ sections or add stiffeners for improved rigidity.

4. How do I confirm that MS channels meet project tolerance requirements?

Check variance against IS measurement standards, verify mill test certificates, and measure sample pieces before full installation to ensure clean alignment.

5. Does SteelonCall support bulk MS channel delivery for façade projects?

Yes. SteelonCall provides verified supplier sourcing, bulk delivery scheduling, and material tracking, helping façade teams maintain uninterrupted execution.