Steel Roof Construction Guide for Builders and Fabricators

A well-built steel roof is more than just a protective shell. It’s an engineered system designed to carry wind, rain, and live loads efficiently over decades with minimal maintenance.

For builders and fabricators, roof performance depends on five essentials: load capacity, watertightness, corrosion protection, thermal behavior, and detailing accuracy. When these are aligned, steel roofing outperforms almost any other roofing system in lifespan, span capability, and installation speed.

Across India, especially in Andhra Pradesh, Telangana, and Karnataka, steel roofs are standard for industrial sheds, logistics warehouses, and commercial structures. Their appeal is simple: long spans with lighter weight, faster erection, and minimal foundation load. Yet, the success of these projects depends on understanding how the roof structure, panel system, and substrate work together.

Key Takeaways

-

Match system to exposure: Standing seam and galvalume for long spans or coastal sites; exposed-fastener galvanized panels for smaller inland roofs.

-

Detailing drives longevity: Underlayment, sealing, and correct fasteners prevent 90% of future leaks.

-

Digital procurement reduces risk: Verified sourcing and transparent pricing streamline large roofing projects.

Steel Roof Structure Fundamentals

A steel roof is an assembly of primary members, secondary framing, and roof panels.

Each performs a distinct function and demands precise fabrication.

Primary members

These include trusses or rafters that carry the main gravity and wind loads.

They transfer roof loads to columns and are typically fabricated from IS 2062 E250/E350 plates or rolled sections.

Secondary members

Purlins, girts, and bracings tie the main trusses together and support roofing sheets.

Cold-formed sections (Z or C profiles) made from galvanized or galvalume-coated steel are widely used for their high strength-to-weight ratio.

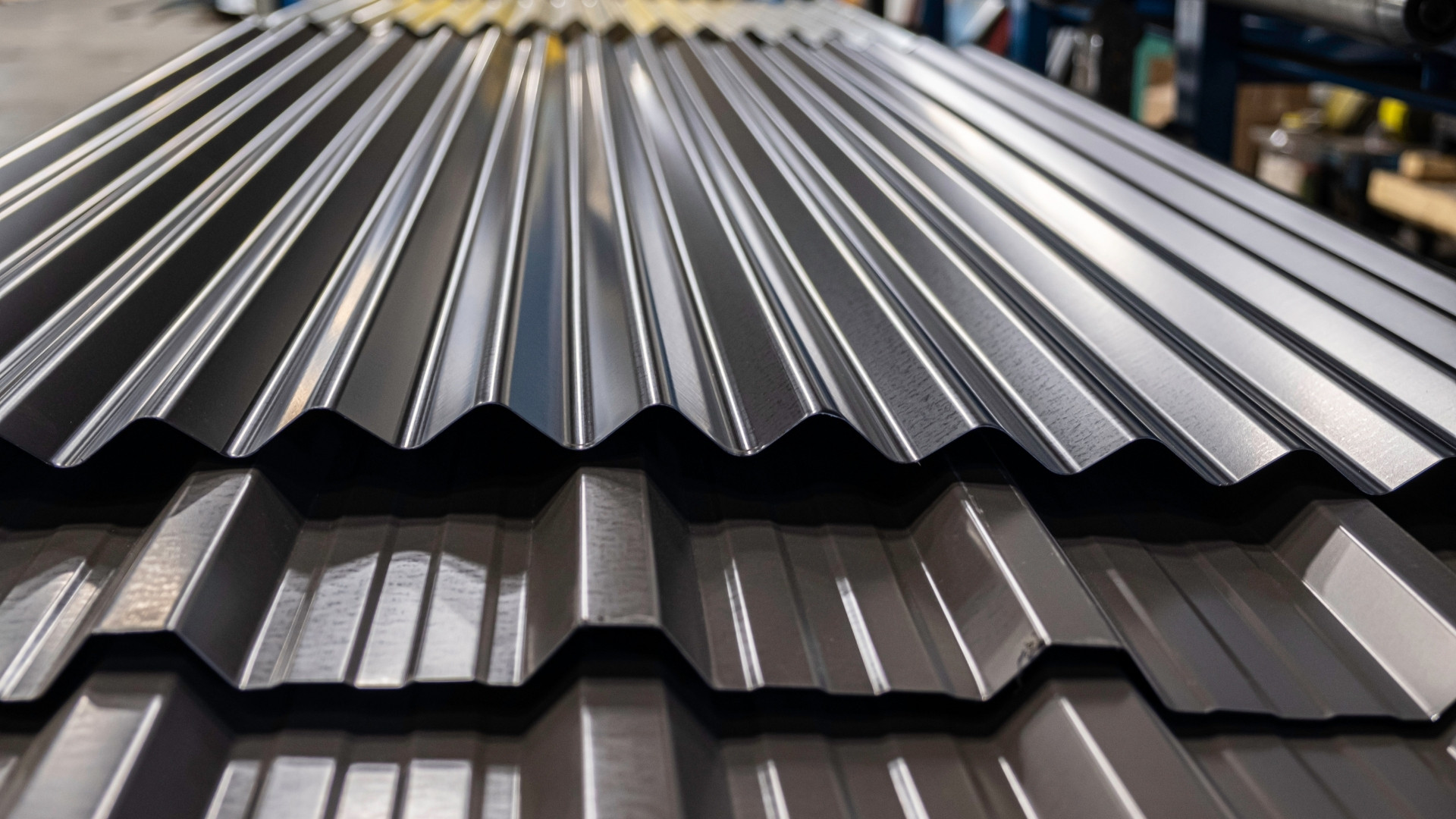

Roof panels

Roofing sheets are the visible surface, galvanized, galvalume, or color-coated steel panels installed as either standing seam (concealed fastener) or exposed-fastener systems.

Their performance depends on coating thickness, fastener quality, and installation precision.

A well-designed roof structure distributes loads uniformly through these components, minimizing deflection, reducing leak risk, and ensuring long-term dimensional stability.

(Also read: Different Types of Roofing Sheets Explained)

Common Steel Roof Trusses and Where They Fit

The truss form dictates how efficiently a roof spans distance, handles uplift, and uses steel tonnage. The best choice depends on span, usage type, and required headroom.

1. Pratt Truss – For Gravity-Dominant Spans

One of the most common configurations for industrial sheds, the Pratt truss uses diagonals in tension and verticals in compression.

It performs best for 20–100-meter spans, where gravity loads dominate and material economy matters.

Pratt trusses are easy to fabricate, repeatable across bays, and simple to erect using bolted or welded connections.

2. Warren Truss – For Balanced Load Paths

The Warren truss features equilateral triangles that distribute loads evenly through both tension and compression members.

It’s ideal for medium spans (up to 60 m) where symmetry, modular fabrication, and uniform member sizes reduce fabrication complexity.

Its geometry provides clear, open webs for HVAC ducts and skylights, which are important in manufacturing sheds.

3. North-Light Truss – For Daylit Workshops

Designed with alternating short and steep slopes, the north-light truss is used where natural lighting and ventilation are priorities.

It suits shorter spans (up to 25 m) and industrial workshops that need diffused daylight without excessive heat gain.

Modern variants often integrate translucent sheets or roof ventilators into the north-facing slopes.

4. Fink Truss – For Small and Medium Roofs

Compact and cost-efficient, Fink trusses are common in residential steel roofs, garages, and smaller commercial buildings.

The web configuration optimizes load paths and allows prefabrication in smaller modules.

Selecting the right truss:

-

For wide-span industrial roofs → Pratt or Warren.

-

For daylight-oriented workshops → North-light.

-

For smaller commercial or residential projects → Fink or Howe variations.

(Also read: Tata Steel vs JSW Steel: A Comparative Analysis)

Panel and Substrate Selection

Choosing the right roofing sheet is just as critical as selecting the truss. The sheet determines the roof’s long-term resistance to corrosion, water ingress, and thermal stress. The wrong substrate or coating can easily shorten a roof’s life by 10–15 years in India’s humid or coastal climates.

Panel System Options

1. Standing Seam Panels

-

Concealed fastener system with raised seams interlocked mechanically or by snap fit.

-

Ideal for large-span industrial or commercial roofs with low pitch.

-

Prevents water seepage since fasteners don’t penetrate the sheet surface.

-

Allows thermal expansion and contraction, important in hot, inland regions like Telangana and Karnataka.

-

Slightly higher upfront cost but lower lifecycle maintenance.

2. Exposed-Fastener Panels

-

Common in warehouses, sheds, and residential roofs.

-

Faster and cheaper to install, but they rely on screw integrity and proper sealing.

-

Need careful tightening of overdriven screws, which cause leaks and oil-canning.

-

Better suited for steep-slope roofs or smaller projects where inspection is easier.

Choosing between the two:

For long-span industrial projects where leaks or corrosion repairs are costly, use standing seam. For budget-sensitive or smaller roofs, well-installed exposed-fastener systems perform adequately.

Substrate and Coating Systems

India’s climate demands coated steel substrates that resist both moisture and heat. The two primary options are galvanized and galvalume steel.

|

Substrate |

Composition |

Best for |

Key Benefit |

|

Galvanized steel |

100% zinc coating (G90/G120) |

Inland and low-humidity zones |

Good sacrificial protection; lower cost |

|

Galvalume steel |

55% aluminium + 43.5% zinc + 1.5% silicon (AZ150) |

Coastal, high-humidity, and hot regions |

2–4× corrosion resistance; better heat reflectivity |

For color-coated systems, use PVDF or SMP paint finishes depending on exposure:

-

PVDF: Long-lasting color retention; ideal for coastal and high-UV conditions.

-

SMP: Cost-effective for inland and moderate exposure areas.

Installation Phases That Protect Performance

The quality of installation determines whether a steel roof meets its design life. Poor fastening, detailing errors, or skipped sealants are the leading causes of early leaks and corrosion. Every installation should follow these core stages.

1. Preparation and Safety

-

Ensure trusses, purlins, and bracings are aligned and free of distortion.

-

Inspect for loose bolts or welding slag that can damage panels.

-

Maintain safe walkways and anchor points for workers; avoid dragging panels on abrasive surfaces.

2. Underlayment and Moisture Control

-

Acts as a secondary barrier against condensation and leaks.

-

Choose between synthetic membranes or bituminous felt, depending on slope and exposure.

-

Maintain a minimum of 150 mm side laps and proper overlaps at ridges and valleys.

-

For large-span or low-slope roofs, install vapour barriers to prevent condensation drip.

3. Panel Layout and Fastening

-

Plan the layout before starting; panels must run square to the eaves.

-

Use correct screw types: self-drilling, EPDM washered fasteners with matching coating (zinc/aluminium).

-

Maintain consistent screw torque. Under-tightening causes uplift; over-tightening causes distortion.

-

For standing seams, use clips with proper spacing to allow expansion.

4. Flashings and Penetrations

-

Detail ridges, valleys, and pipe boots with sealant-backed flashings.

-

Avoid direct metal-to-metal contact between dissimilar materials (e.g., copper and steel).

-

Use compatible sealants, neutral-cure silicone or butyl-based sealants are preferred.

5. Drainage and Edge Metal

-

Design for monsoon rainfall intensity (≥75 mm/hr in southern India).

-

Incorporate gutters, downpipes, and overflow scuppers with adequate slope.

-

Ensure eaves and drip edges prevent backflow or standing water at joints.

(Also read: 1 Ton Steel Price Today in India)

Environmental Factors in Indian Conditions

Steel roofs in India face a wide range of environmental pressures—from heavy monsoon rain to coastal humidity and high solar loads. Each condition demands design adjustments that directly influence roof life and maintenance needs.

Monsoon-Driven Moisture

-

Roof slope should be ≥5° for exposed-fastener and ≥2° for standing seam systems.

-

Fasteners and laps must be sealed against heavy wind-blown rain.

-

Coastal sites require AZ150 galvalume or equivalent substrates and stainless fasteners.

Heat and Solar Load

-

Steel’s high conductivity demands reflective coatings and ventilation gaps.

-

PVDF-coated galvalume roofs can reflect up to 70–80% of solar radiation, reducing interior heat gain and cooling loads.

Wind Uplift and Cyclone Resistance

-

Proper purlin spacing and clip design are essential in high-wind zones along the East Coast.

-

Use ISI-certified fasteners and wind-resistant panels tested under ASTM E1592 or equivalent.

Maintenance Strategy

-

Clean debris quarterly, especially around valleys and gutters.

-

Inspect fasteners annually for back-out or corrosion.

-

Touch up cut edges with zinc-aluminium-rich paint during routine maintenance.

Common Mistakes and How to Avoid Them

Even well-specified steel roofs can fail early if installation shortcuts or design oversights creep in. Here are the most frequent causes of performance loss and how to prevent them.

1. Improper Fastening

-

Overdriven screws distort the sheet and crush washers, allowing moisture seepage.

-

Underdriven screws create uplift gaps during high winds.

-

Always use torque-controlled drills and fasteners with EPDM or neoprene washers matched to the panel coating.

2. Incorrect Lap Orientation

-

Placing side laps against prevailing wind direction or skipping sealant beads causes leakage at joints.

-

Verify lap direction during panel layout; seal laps with compatible butyl tape or neutral-cure silicone.

3. Skipping Underlayment or Ventilation

-

Omitting underlayment leads to condensation drip, especially in humid zones.

-

Without roof ventilation, trapped heat accelerates coating degradation.

-

Always include ridge vents or turbo ventilators for heat exhaust.

4. Contact Between Dissimilar Metals

-

Galvanized sheets reacting with copper or bare aluminium can corrode prematurely.

-

Use nylon or rubber isolation washers between dissimilar materials.

5. Neglecting Maintenances

-

Ignoring clogged gutters or loose screws invites leaks and rust pockets.

-

A simple biannual inspection extends roof life dramatically, especially in coastal regions.

(Also read: How to Prevent Corrosion in Steel)

Quick Selector for Typical Projects

The right truss, panel, and substrate combination depends on project type, exposure, and maintenance access.

|

Project Type |

Recommended Truss / Framing |

Roof Panel System |

Substrate & Coating |

Notes |

|

Industrial Shed (Inland) |

Pratt or Warren Truss |

Exposed-Fastener Panels |

Galvanized (G90) |

Cost-effective; moderate maintenance |

|

Logistics Warehouse (Wide Span) |

Warren or Fink Truss |

Standing Seam Panels |

Galvalume (AZ150) + PVDF |

Better leak control and long-span capacity |

|

Coastal Factory / Port Zone |

Pratt or North-Light |

Standing Seam Panels |

Marine-grade Galvalume + Stainless Fasteners |

High corrosion resistance |

|

Commercial Roof with Solar Mounts |

Warren or Space Frame |

Standing Seam Panels |

Galvalume + PVDF |

Supports clamp-based solar installation |

|

High-Bay Workshop (Daylighting) |

North-Light Truss |

Exposed-Fastener Panels with Skylights |

Galvanized + SMP |

Balanced lighting and cost efficiency |

How SteelonCall Supports Steel Roof Projects

For builders and fabricators managing large roofing orders, SteelonCallsimplifies the sourcing process by integrating verified supply, pricing transparency, and logistics reliability into one digital platform.

-

Verified Manufacturers: Access coated steel products from vetted mills and brands compliant with IS 277 (Galvanized) and IS 15961 (Galvalume) standards.

-

Direct Mill Access: Procure sheets, purlins, and truss sections directly, reducing middlemen and project delays.

-

Live Regional Prices: Compare material costs across Andhra Pradesh, Telangana, and Karnataka through live pricing charts.

-

Bulk and Custom Orders: Specify sheet gauge, width, or coating (G90, AZ150) directly in the order request.

-

End-to-End Delivery: SteelonCall’s logistics coordination ensures safe, timely supply to construction sites.

For modern roofing projects, this kind of transparent procurement minimizes both cost overruns and material inconsistencies, two common issues in traditional steel supply chains.

Conclusion

Steel roofing has redefined modern construction, combining speed, durability, and architectural flexibility. When executed with the right truss system, coated substrate, and detailing discipline, it offers a 30-year-plus service life even under India’s demanding weather.

For builders and fabricators, the next frontier isn’t just installation, it’s smarter procurement and lifecycle planning. We at SteelonCall make that shift practical, ensuring every project benefits from verified materials and predictable supply.

Explore Coated Steel Roofing Materials at Live Prices

Source galvanized and galvalume sheets, truss sections, and purlins directly from verified manufacturers.

Check Live Prices →

Frequently Asked Questions

1. What is the lifespan of a steel roof in Indian conditions?

Typically 30–50 years, depending on substrate (galvanized vs galvalume), coating quality, and maintenance. Standing seam systems generally outlast exposed-fastener roofs due to fewer penetrations.

2. Which truss design is best for wide-span sheds?

Pratt or Warren trusses are most efficient for industrial spans of 20–100 m. They balance weight and load distribution while remaining easy to fabricate.

3. Is Galvalume better than galvanized for roofing?

Yes. Galvalume’s aluminum-zinc coating gives 2–4× longer corrosion resistance, especially in coastal or humid zones.

4. How often should fasteners and sealants be checked?

Inspect at least twice a year, preferably before and after monsoon season, to tighten loose screws and replace cracked sealants.

5. Can solar panels be installed on steel roofs?

Absolutely. Standing seam systems are ideal for clamp-mounted solar installations, eliminating the need for roof penetrations.