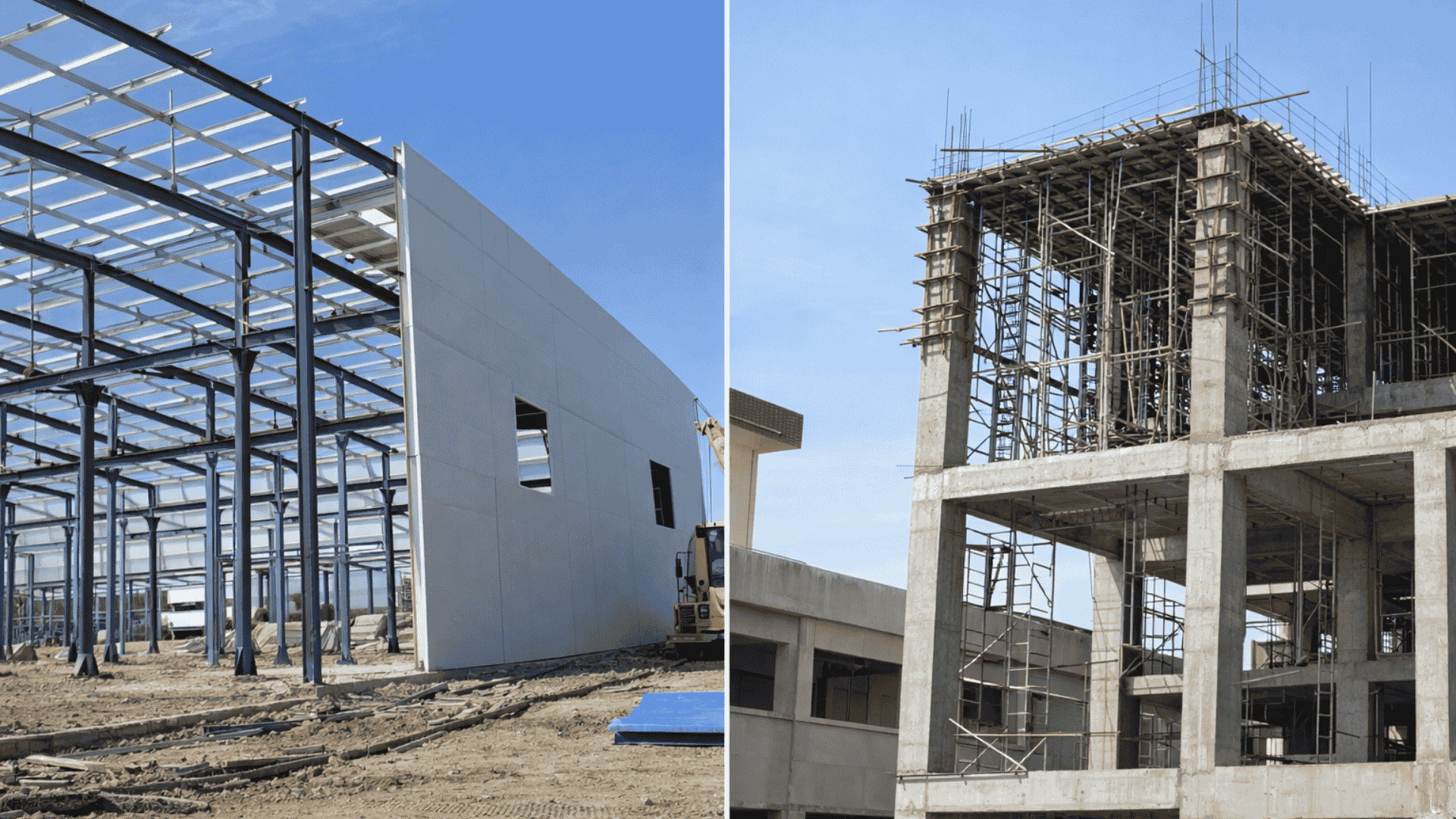

Steel Structure vs RCC Structure: Pros and Cons for Builders in South India

Choosing the right structural system for your project can feel like running through a maze. Whether it's a steel frame or an RCC system, each option has its own set of benefits and challenges. For contractors and builders, the uncertainty of which material to choose can lead to costly delays, unexpected budget overruns, and confusion over long-term performance.

This blog breaks down the pros and cons of steel structure vs RCC structures, focusing on what really matters to your project's success, from cost efficiency to construction speed. By the end, you'll have the clarity you need to make the right choice and keep your project on track.

Key Takeaways:

-

Steel structures reduce construction time compared to RCC, making them ideal for time-sensitive projects.

-

RCC is more cost-effective upfront, but steel's faster assembly can offset those costs by reducing labour and project duration.

-

Steel offers flexibility for large spans and clear spaces, while RCC is ideal for conventional load-bearing applications in residential and low-rise buildings.

-

Steel provides better seismic performance, absorbing lateral loads more effectively than RCC, which can be crucial in earthquake-prone zones.

-

Steel structures are faster to assemble and offer greater design flexibility, whereas RCC is well-suited to conventional projects with predictable requirements.

Steel Structure vs RCC Structure: A Brief Answer

For construction in hot climates like Andhra Pradesh, Telangana, and Karnataka, choosing between a steel structure and an RCC (reinforced cement concrete) structure depends on what matters most for your project timeline and performance.

In general terms:

-

Steel structures are typically faster to erect, thanks to off‑site fabrication and on‑site assembly, often saving significant construction time compared to RCC systems. Steel structures can reduce construction time by roughly 18–32% compared to traditional RCC, because RCC requires curing and formwork cycles that add weeks to schedules.

-

RCC structures often have lower initial material costs and strong compressive strength, making them widely used for residential and conventional multi‑storey projects where speed isn't the primary constraint.

The best choice hinges on your project priorities. Speed and flexibility (steel) or traditional cost and compressive strength (RCC) are the bigger drivers for your site conditions and delivery timelines.

Now that you know the basic comparison, let's get into the fundamentals to understand how each system supports the loads and stresses of your building.

What Are Steel and RCC Structures?

In construction, the framing system you choose determines how loads are carried, how fast the building goes up, and how the structure behaves under stress.

Two of the most common structural systems are steel structures and RCC (Reinforced Cement Concrete) structures, each built to support the weight and forces in a building, but with different materials and performance characteristics.

Steel Structure Basics

Steel structures use steel members, beams, columns, and trusses that are fabricated off-site and assembled on-site.

-

High strength‑to‑weight ratio: Steel delivers substantial load‑bearing capacity with less weight than concrete. This characteristic leads to lighter foundations and more efficient use of materials.

-

Fast on‑site assembly: Structural steel components can be pre‑fabricated and bolted or welded together quickly, reducing the overall construction schedule.

-

Flexibility with design: Steel's ductility makes it well-suited for seismic zones and dynamic loads, as it can absorb and redistribute stresses more effectively than rigid systems.

Steel's inherent strength and speed of erection make it especially attractive for large industrial, commercial, and high‑rise project frameworks.

RCC Structure Basics

RCC structures use reinforced concrete, in which steel bars (rebars) are embedded in concrete to create a composite system. Concrete resists compressive forces, while the embedded steel bars handle tensile forces.

-

Strong under compression: RCC has long been favoured for multi‑storey residential and conventional projects because it performs well under vertical loads due to concrete's high compressive strength.

-

Site‑dependent construction: RCC systems rely on in‑situ casting, formwork, placing reinforcement, pouring concrete, and curing, which takes scheduled time and on‑site labour.

-

Proven track record: For decades in Indian construction, RCC has been considered economical and reliable for low- to mid‑rise buildings, balancing speed of execution with lower upfront material costs.

These core distinctions set the practical context for the deeper pros-and-cons comparisons that follow, helping you decide which system aligns with your project's priorities.

Suggested Read: How To Choose The Right Structural Steel For Your Project

Steel Structure vs RCC Structure: A Side‑by‑Side Comparison

When choosing between steel and RCC structures for your project, understanding their key differences is crucial to making the right decision.

Let's compare both systems across critical factors like construction time, cost, strength, seismic behaviour, and maintenance needs.

This will help you determine which system is the best fit for your project goals.

| Factor | Steel Structure | RCC Structure | Why It Matters to Your Project |

|---|---|---|---|

|

Construction Time |

Faster than RCC due to prefabrication and minimal on‑site curing. |

Slower due to formwork, casting, and curing cycles. |

Faster schedules help meet deadlines and reduce labour overlap issues. |

|

Initial Cost |

Higher initial structural cost. |

Typically lower upfront cost for material and basic labour. |

Upfront budgeting and cash flow planning differ by system. |

|

Strength Characteristics |

High strength‑to‑weight ratio allows long spans and lighter foundations. |

Excellent compressive strength and mass, ideal for conventional residential loads. |

Affects frame design, foundation needs, and seismic performance. |

|

Ductility & Seismic Performance |

Better ductile performance under lateral loads, reducing base shear forces in earthquakes. |

Generally, more rigid structures with higher mass can elevate seismic forces. |

Crucial in earthquake‑prone zones. |

|

Maintenance Needs |

Requires corrosion protection in humid/tropical climates; paint/coatings add long‑term reliability. |

Concrete is inherently corrosion‑resistant but can crack over time and need repairs. |

Influences lifecycle expense planning. |

|

Design Flexibility |

Highly adaptable to custom shapes, large spans, and modular changes. |

More rigid forms and complex shapes increase the amount of shuttering and labour required. |

Affects future expansion and architectural complexity. |

|

Fire Resistance |

Steel needs protective coatings; structural strength drops rapidly above certain temperatures without fireproofing. |

Concrete inherently resists high temperatures, and fire spreads without extra treatment. |

Impacts safety planning and code compliance. |

This table provides a practical snapshot to help you assess steel structures vs. RCC structures based on project priorities, including speed, cost, load performance, and structural resilience.

Now that you have a snapshot of how both systems perform, let's look at the key decision factors that will guide your choice.

Key Decision Factors for Choosing Steel or RCC Structures

Selecting between steel and RCC for your building project isn't just about material. It’s about how that choice will affect cost, schedule, performance, and long‑term durability on your specific site.

Based on a comparison of structural systems, here are the key criteria to weigh before making your decision:

1. Construction Time & Schedule Efficiency

One of the most consistent findings in structural studies is that steel structures significantly speed up construction cycles compared to traditional RCC.

-

Steel structures can reduce construction time compared to RCC, primarily because steel components are prefabricated off‑site and don't require the lengthy formwork and curing cycles associated with concrete.

-

For time‑sensitive projects in Andhra Pradesh, Telangana, or Karnataka, this speed advantage can translate into faster handovers and reduced labour overlap costs.

What to consider on site: If your project has tight delivery windows or phased milestones, faster steel erection can shorten the critical path.

2. Upfront Cost vs Lifecycle Cost Planning

Cost is a key consideration early in planning, but it must be seen in the context of total project cost over time:

-

A typical steel structure can cost about 38.19% more upfront than an equivalent RCC structure for the same building plan and load conditions.

-

However, these upfront costs can be offset by reduced labour and overhead due to faster construction, especially on larger or industrial sites.

What to consider on site: Look at both initial budget and project duration costs to determine the more economical choice.

3. Structural Performance Needs

Different project types have distinct performance requirements:

-

Steel offers a high strength-to-weight ratio, allowing longer spans with lighter frames. It is especially useful for warehouses, industrial sheds, and buildings that require clear open spaces or large column‑free areas.

-

RCC provides robust compressive strength ideal for conventional load paths in smaller residential or standard commercial buildings.

What to consider on site: Match the structural system to your load requirements and spatial design. Steel for long spans and flexibility, RCC for conventional layouts.

4. Seismic & Dynamic Behaviour

Performance under lateral loads and seismic activity varies with structural type:

-

Steel frames often have higher ductility and energy absorption, which can improve resilience in earthquake‑affected regions.

-

Although RCC may exhibit stable behaviour in certain configurations, the steel's ability to deform without sudden failure gives it an edge in seismic zones.

What to consider on site: In areas with seismic risk or structural codes requiring ductile design, steel systems often meet dynamic performance goals more effectively.

5. Maintenance & Longevity in Hot Climates

Maintenance needs influence lifecycle planning:

-

Steel structures require protective measures like coatings or galvanisation to resist corrosion in humid or tropical climates, a factor in coastal or monsoon‑affected areas.

-

RCC is inherently resistant to corrosion but can develop surface cracks due to thermal stress or shrinkage, requiring periodic patching.

What to consider on site: Balance preventive maintenance planning with local environmental conditions to ensure long‑term performance.

These factors will help you choose the most appropriate structural system for your next build in South India's climate and site conditions.

With these in mind, it's time to explore practical scenarios in which one system outperforms the other, helping you determine the right fit for your project needs.

When to Choose Steel vs RCC: Use Case Scenarios

In real construction projects, the decision between a steel structure and an RCC structure isn't one‑size‑fits‑all. Each system fits certain use cases better based on load demands, timeline constraints, design complexity, and performance expectations.

These materials behave differently under specific conditions, helping you match structural choice to project type rather than defaulting to tradition.

1) Industrial & Large‑Span Buildings

For structures with large, unobstructed interior spaces, such as factories, warehouses, aircraft hangars, and exhibition halls, steel structures are often the preferred choice due to their high strength‑to‑weight ratio and ability to span long distances without intermediate support.

This minimises foundation size and column obstructions, improving workflow and material handling within the space.

2) High‑Rise & Multi‑Storey Structures

Tall buildings demand structures that balance strength, ductility, and constructability. Composite systems (steel-concrete hybrids) are often used in high-rise applications because they combine steel's tensile strength with concrete's compressive stability, leading to improved seismic response and lower total weight.

3) Residential & Low‑Rise General Construction

Conventional residential buildings, townships, and low‑rise commercial projects often favour RCC structures due to the wide availability of local labour and materials and generally lower initial material cost. RCC's inherent compressive strength and thicker sections provide good stability for typical load paths encountered in low‑rise design.

4) Hybrid & Composite Structures

In many modern projects, especially medium and high‑rise buildings, steel‑concrete composite systems are emerging as a preferred option because they offer a balanced mix of strength, speed, and cost effectiveness.

Composite structures can achieve lower overall cost and better performance than pure steel or pure RCC in certain mid‑to high‑rise contexts.

Having explored the various scenarios, see how sourcing materials through an efficient marketplace like SteelonCall can ease your procurement process and ensure timely delivery.

How SteelonCall's Marketplace Helps You Source Better

SteelonCall is an online steel marketplace designed to meet the unique needs of construction projects, particularly when sourcing materials for steel and RCC structures.

For builders and project managers in South India, the challenges of material performance, quality assurance, and reliable delivery are amplified by the demanding local conditions.

Here are some key advantages:

-

Verified Supplier Network for Quality Assurance

SteelonCall connects you to a robust network of verified suppliers, ensuring that every steel or RCC component is sourced from trusted manufacturers. This reduces the risk of receiving substandard materials or incorrect grades.

-

Direct Access to Trusted Manufacturers

SteelonCall provides direct access to trusted manufacturers, including Vizag Steel, offering an authentic supply of structural steel and reinforcement products. By eliminating intermediaries, you get consistent quality and competitive pricing.

-

Strong Regional Presence in South India

With a strong operational presence in Andhra Pradesh, Telangana, and Karnataka, SteelonCall is equipped to manage the specific demands of regional construction projects. This allows for better local procurement planning and more reliable delivery timelines.

-

Support for Bulk and Custom Orders

SteelonCall understands that large construction projects require specific steel grades and custom sizing. Whether it's for long spans, structural beams, or reinforcement, SteelonCall supports bulk orders and customised material requests.

-

End‑to‑End Logistics Coordination

SteelonCall's end-to-end logistics management ensures smooth, reliable delivery, from supplier dispatch to site delivery. This reduces handling risks, ensures materials arrive on schedule, and guarantees safe, secure transportation.

SteelonCall's marketplace offers live pricing and availability checks. By entering your project's pin code, you can instantly access the best materials, ensuring your project remains on schedule without delays or unexpected price hikes.

Conclusion

Choosing between steel and RCC structures involves evaluating key factors like cost, construction time, strength, and long-term performance. Steel structures are faster to assemble and offer greater design flexibility, while RCC systems are more cost-effective up front and well-suited to conventional load-bearing applications.

The right choice depends on your project's specific needs, including speed, budget, performance, and durability. SteelonCall offers a reliable online marketplace with verified suppliers and direct access to trusted manufacturers, including Vizag Steel, ensuring the right materials at competitive prices.

Check SteelonCall's latest prices and availability to source steel or RCC materials customised to your project needs today.

FAQs

1. Is a steel structure always stronger than an RCC structure?

Not necessarily. Steel has a higher strength‑to‑weight ratio and performs better under tension and dynamic loads, while RCC excels in compressive strength due to concrete's properties. The best choice depends on your structural load requirements.

2. Which structural system handles seismic loads better?

Steel structures generally offer greater ductility and energy absorption under lateral (earthquake) forces than RCC, which tends to be more rigid and heavier, potentially increasing seismic demand.

3. Does the choice between steel and RCC affect usable interior space?

Yes. Steel's high strength‑to‑weight ratio allows longer clear spans with fewer columns, increasing usable floor space. RCC typically requires more frequent columns due to heavier members.

4. Are steel structures more expensive than RCC structures?

Steel structures often have higher upfront material and fabrication costs than RCC due to steel pricing and specialised assembly, though faster erection can offset some labour costs on larger projects.

5. Can RCC structures be faster to build than steel in some cases?

Usually not. Steel systems are prefabricated off‑site and erected quickly, while RCC requires on‑site formwork, casting, and curing, which adds time to the schedule.