Structural Steel vs Stainless Steel for Builders

Choosing the wrong steel for a project rarely shows its impact on day one. It shows up later as rising costs, fabrication issues, or delays that push site schedules off track. For builders and fabricators, the confusion between structural steel and stainless steel often begins at the sourcing stage. One wrong call can mean overpaying, compromising strength, or dealing with materials that do not perform as expected on site.

This blog is meant to clear that confusion. It breaks down the key differences between structural steel vs stainless steel from a practical, project-focused perspective. By the end, you will know which material fits which type of construction or fabrication need, how that choice affects cost and timelines, and how to make a more confident steel sourcing decision without slowing your project down.

Key Takeaways

-

Structural steel is well-suited to heavy load-bearing work where cost, scale, and fabrication speed matter most.

-

Stainless steel is best for exposed or corrosive environments, not for full structural frames.

-

Material choice affects delivery and fabrication timelines, not just design performance.

-

Over-specifying stainless steel increases costs without added value in protected structural zones.

-

Correct sourcing is as important as correct material selection to avoid grade mismatch and project delays.

What This Comparison Means for Your Project

At a practical level, the comparison between structural steel vs stainless steel comes down to this:

-

Structural steel is chosen where load-bearing strength, scalability, and cost-efficiency are critical.

-

Stainless steel is chosen where corrosion resistance, exposure conditions, or long-term durability justify a higher material cost.

For most building structures, frames, and heavy fabrication work, the decision directly affects budget control, fabrication ease, and delivery timelines.

Material choice is not just a design decision. It directly affects how smoothly a project runs.

From a site and procurement perspective, structural steel is generally easier to source in bulk, fabricate, and deploy for large spans and RCC frameworks. Stainless steel often involves higher procurement costs, specialised handling, and longer lead times, especially for bulk or custom sections.

In regions like Andhra Pradesh, Telangana, and Karnataka, where projects often run on tight schedules and phased deliveries, this difference can influence:

-

Whether fabrication starts on time

-

Whether site work pauses due to delayed material

-

Whether costs remain predictable across project stages

This comparison helps project teams align material choices with the actual application, rather than relying on assumptions or supplier-driven suggestions.

Also Read: How to Prevent Corrosion in Steel: Tips for Builders & Fabricators

To make the right call on site, let's see the core differences that help to break down how these two materials differ in real, measurable ways.

Structural Steel Vs Stainless Steel: Core Differences

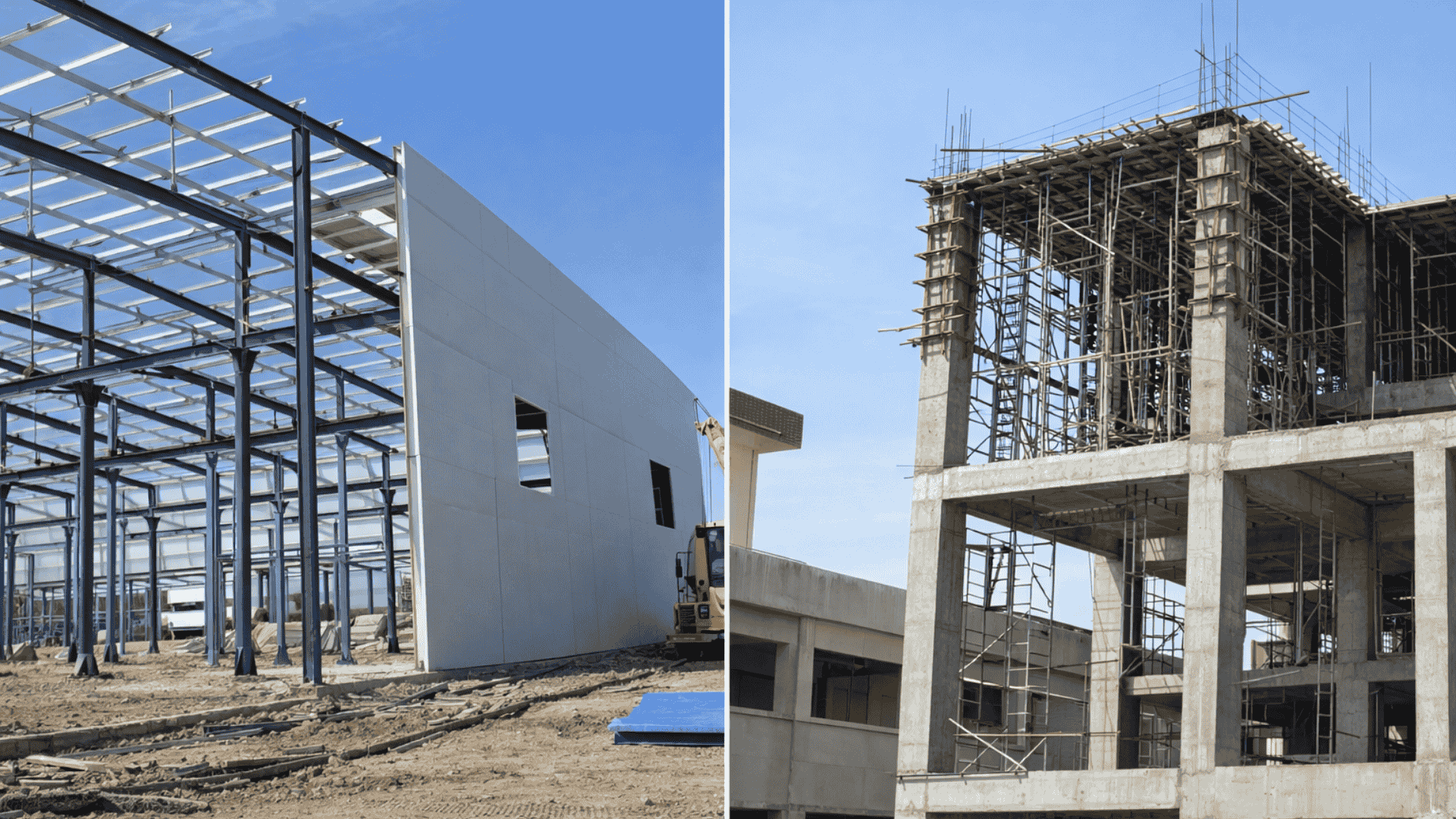

Structural steel and stainless steel are both widely used in construction and fabrication, but they serve different purposes. One is optimised for load-bearing efficiency and scale, while the other is built for corrosion resistance and long-term durability.

The differences are not academic. They directly affect project cost, fabrication planning, maintenance effort, and delivery timelines.

1. Strength & Load-Bearing Differences

From a project selection standpoint:

-

Structural steel comes with well-established strength metrics that are easy to specify for load-bearing members across building frames and bridges.

-

Stainless steel can achieve comparable strength in certain grades (e.g., duplex stainless steels with balanced ferritic-austenitic microstructures that can approach higher proof strengths), but it is not the default choice for primary structural frames due to cost and fabrication considerations.

In everyday construction across Andhra Pradesh, Telangana, and Karnataka, structural steel remains the go-to for beams, columns, and bracing, with strength-to-cost and ease of fabrication as key considerations.

2. Corrosion Performance in Practice

Corrosion performance matters where:

-

The structure is exposed to moisture, salts, or chemical atmospheres.

-

Protective paints/coatings may wear off over time.

Stainless steel forms a passive chromium oxide film that self-repairs when scratched, significantly reducing the risk of long-term corrosion.

In contrast, structural steel needs ongoing protective systems (galvanisation, coatings) and inspection to maintain service life in corrosive environments.

For project managers in coastal or humid zones, this means factoring maintenance costs and coating schedules into long-term planning.

3. Fabrication & Welding Behaviour

Fabrication flow impacts schedule and cost:

-

Structural steel is widely known and easy to weld with standard MIG/TIG/SMAW methods, making it faster to fabricate on-site or at workshops.

-

Stainless steel's alloying elements and passive layer require controlled welding practices to avoid intergranular corrosion, especially when heat-affected zones are not properly managed.

This can translate into differences in fabrication lead time and the need for skilled welders, a practical consideration when planning procurement and on-site workstreams.

4. Procurement & Budget Considerations

-

Structural steel is typically more cost-effective for large-tonnage framing because its composition and processing are less alloy-intensive.

-

Stainless steel commands a premium due to alloying elements like chromium and nickel, as well as the extra refinement they require.

For someone planning large-scale sourcing, this means balancing upfront material cost with performance needs, and factoring that into tender budgets, supplier negotiations, and delivery forecasts.

Knowing the differences is one thing. Applying them correctly to real construction and fabrication scenarios is where decisions are won or lost.

How These Differences Affect Construction & Fabrication Decisions

Once the technical differences are clear, the real question becomes how they play out in actual projects. Material selection decisions are rarely theoretical.

For contractors, fabricators, and project managers, the choice between structural steel and stainless steel usually comes down to where strength, exposure, budget, and maintenance intersect.

Where Structural Steel Makes the Most Sense on Site

Structural steel is typically the default choice when the project needs high load capacity at scale, fast fabrication, and predictable procurement.

Most common fits:

-

Building frames: beams, columns, and bracing for commercial and industrial sheds

-

Heavy supports: platforms, pipe racks, mezzanines

-

High-tonnage work: where cost per ton and lead time drive procurement decisions

In day-to-day project planning, this choice usually reduces:

-

Fabrication complexity (standard cutting/welding workflows)

-

Sourcing friction (bulk ordering is simpler for common sections)

-

Cost risk (fewer “premium-grade” surprises during procurement)

Practical decision cue: If the member is covered/protected (coated/painted/clad) and not directly exposed to harsh environments, structural steel usually gives the best strength-to-cost outcome.

When Stainless Steel Is Worth Specifying

Stainless steel is best treated as a targeted specification, not a blanket replacement.

It becomes worthwhile when exposure conditions create a long-term corrosion risk that’s expensive to manage with coatings alone.

Common project scenarios:

-

Coastal or salt-exposure zones (for example, areas around Visakhapatnam and coastal Andhra): chloride exposure increases corrosion risk for conventional steel.

-

High-humidity / wet-process environments (certain industrial setups where condensation and washdowns are routine)

-

Visible architectural elements where surface appearance matters over time (handrails, cladding supports, exterior fixtures)

Practical decision cue: If the component is exposed, hard to repaint/maintain, or in a chloride-prone environment, stainless can reduce lifecycle maintenance effort.

If you need a faster way to evaluate options during planning or procurement discussions, the comparison below simplifies the decision.

Quick Decision Table: Structural Steel vs Stainless Steel for Construction Projects

When projects move from design to execution, material discussions often turn into lengthy back-and-forths among site teams, consultants, and procurement teams. At that stage, what teams need is not more explanation; they need clarity.

This quick decision table is designed as a practical reference for contractors, fabricators, and project managers

| Decision Parameter | Structural Steel | Stainless Steel | What This Means for the Buyer |

|---|---|---|---|

|

Primary Role |

Load-bearing structural backbone |

Corrosion-resistant, durability-focused material |

Choose based on whether strength or exposure control is the priority |

|

Typical Use in Projects |

Beams, columns, trusses, frames, industrial sheds |

Exposed supports, coastal structures, and architectural elements |

Avoid using stainless where it doesn't add functional value |

|

Strength-to-Cost Efficiency |

High — designed for carrying large loads at scale |

Lower — strength achievable, but at a higher cost |

Structural steel is more economical for large tonnage |

|

Corrosion Handling |

Needs coatings, galvanisation, or periodic repainting |

Built-in corrosion resistance via alloy composition |

Stainless reduces long-term surface maintenance in exposed zones |

|

Fabrication Speed |

Faster — standard cutting and welding processes |

Slower — needs controlled welding and finishing |

Impacts fabrication timelines and manpower planning |

|

Bulk Availability |

Widely available in standard sections |

Often limited to specific profiles and quantities |

Structural steel is easier to plan for phased deliveries |

|

Maintenance Over Lifecycle |

Higher in exposed conditions |

Lower when correctly specified |

Maintenance planning affects long-term project costs |

|

Best Fit Environments |

Covered or protected structural zones |

Coastal, humid, chemical, or wet-process environments |

Match material to environmental exposure, not assumptions |

|

Budget Impact |

Lower upfront cost |

Higher upfront cost |

Avoid over-specification that inflates budgets unnecessarily |

This table is designed to help project teams align material choices with actual site conditions, budget constraints, and delivery planning, rather than relying on generic rules of thumb.

Once the right material is identified, the next challenge is executing that decision accurately through sourcing and delivery.

How SteelonCall Helps with Structural and Stainless Steel Selection & Supply

Choosing between structural steel and stainless steel is only half the decision. The real challenge begins when project teams need the exact grade, brand, and quantity delivered as approved, without substitutions or scheduling disruptions.

For contractors, fabricators, and project managers handling mixed steel requirements, SteelonCall's online steel marketplace model becomes relevant because it brings clarity, control, and accountability into the sourcing process.

Below are the key reasons SteelonCall aligns well with projects:

-

Verified Supplier Network

SteelonCall works with a verified network of suppliers, ensuring that the steel grade approved in the drawings is the grade delivered to the site. Buyers are protected from last-minute material substitutions

-

Direct Access to Trusted Manufacturers

SteelonCall enables access to established manufacturers, with Vizag Steel prioritised when discussing major construction-grade steel brands. This direct manufacturer access helps ensure consistent grade supply across project phases.

-

Strong Regional Presence

SteelonCall has strong operational depth in Andhra Pradesh, Telangana, and Karnataka. This regional grounding supports better coordination with local supply networks and faster resolution of region-specific sourcing challenges.

-

Support for Bulk Requirements

SteelonCall supports bulk orders of structural steel for frames and supports. Targeted stainless steel requirements for exposed or specialised elements align with phased construction and fabrication schedules

-

End-to-End Delivery Coordination

SteelonCall coordinates deliveries from supplier dispatch to site arrival, helping project teams match delivery timelines with fabrication and erection plans. This becomes critical when different steel types are required at different stages.

SteelonCall is an online steel marketplace that helps project teams move from material comparison to accurate sourcing, reliable delivery, and smoother execution, especially when projects involve both structural steel and stainless steel.

Conclusion

Each material choice comes with trade-offs. Understanding the differences between structural steel vs stainless steel helps project teams decide where strength, cost efficiency, and scale matter most, and where corrosion resistance and long-term durability justify a higher specification.

Once the right material is identified, sourcing it correctly becomes the next critical step. Through its online steel marketplace, SteelonCall enables builders, fabricators, and project teams in South India to check availability and get online pricing for structural steel and stainless steel from verified sources, with reliable delivery planning.

Check the latest prices and place your requirement today to keep material decisions aligned with project schedules and cost control.

FAQs

1. Can stainless steel replace structural steel in load-bearing construction?

Stainless steel can handle structural loads in specific grades, but it is rarely used as a full replacement due to higher cost and fabrication complexity. Most projects use it selectively, not for entire frames.

2. Is stainless steel always better for coastal or humid environments?

Not always. Stainless steel performs better in corrosive conditions, but the grade selection matters. In many cases, coated or galvanised structural steel may still be sufficient and more cost-effective if maintenance access is manageable.

3. Does using stainless steel reduce long-term maintenance costs?

Yes, in exposed or hard-to-access areas. Stainless steel can reduce repainting and corrosion-related repairs. However, for protected structural members, the maintenance cost advantage may not justify the higher upfront price.

4. Are delivery timelines different for structural steel and stainless steel?

Yes. Structural steel sections are generally available faster in bulk, while stainless steel may require longer lead times, especially for non-standard sizes or higher grades. This can affect fabrication and site sequencing.

5. Should material choice be decided by the designer or the procurement team?

Ideally, both. Designers define performance needs, but procurement teams add value by evaluating availability, lead times, and cost impact. Early coordination helps avoid over-specification and sourcing delays later.