6 Types of Steel Beams Used In Construction

Structural failures often trace back to one critical error: incorrect beam selection. A building's entire integrity depends on the hidden steel skeleton supporting it. Miscalculations in beam type or size risk costly corrections and potential safety hazards.

The correct specification of steel beams used in construction prevents these structural and financial risks. This ensures optimal load-bearing capacity, design flexibility, and long-term stability for any project.

This guide outlines the common types of structural steel beams used in construction projects. It covers their specific applications, standard specifications, and key selection criteria to help you make informed sourcing decisions.

Key Takeaways

-

I-beams and H-beams are the most common types, chosen for their exceptional strength-to-weight ratio.

-

The choice between beam types depends entirely on the specific load and span requirements of your design.

-

Channels like PFCs and Angles are essential for supporting structures and bracing.

-

Beam specifications should be verified, including depth, flange width, and weight per metre.

-

Understanding manufacturing processes like hot-rolling helps you assess beam quality and suitability.

-

Correct beam selection directly impacts the safety, cost, and speed of your construction project.

What Are Steel Beams?

Steel beams are horizontal structural elements that carry loads across a span. They primarily resist bending forces and transfer loads to columns and foundations. Their cross-sectional shape, like an 'I' or 'H', provides maximum strength with minimal material.

Beams form the essential framework for floors, roofs, and support systems in buildings and bridges. Builders and fabricators rely on them for their high strength and predictable performance.

Also read: HR Sheet vs CR Sheet: Differences, Uses & Buying Guide

Knowing what steel beams are leads to understanding their critical role. Their importance becomes clear when examining the specific advantages they offer construction projects.

Why Are Steel Beams Important In Construction?

Steel beams provide the critical framework that makes modern construction possible. They offer advantages that directly impact your project's feasibility, safety, and efficiency.

Understanding these benefits justifies their fundamental role in your building designs. Here are the core reasons for their importance:

1. Superior Load-Bearing Capacity

Steel beams support immense weights over long spans without structural failure. This allows for open floor plans and large, column-free spaces in commercial buildings. You can design wider openings and support heavier loads with confidence.

2. Design Flexibility and Adaptability

You can fabricate steel beams into various shapes and lengths to meet specific design needs. This flexibility supports innovative architectural designs and complex structural requirements. It enables custom solutions for unique project challenges.

3. Proven Durability and Longevity

High-quality steel beams resist corrosion, deformation, and pest damage effectively. They maintain their structural integrity for decades with minimal maintenance needs. This long service life ensures the building's safety and reduces long-term costs.

4. Cost-Effective Construction Speed

Prefabricated beams arrive on-site ready for quick assembly with bolted or welded connections. This speeds up the structural framing process compared to cast-in-place concrete. Faster erection leads to earlier project completion and reduced labour costs.

Also read: How to Calculate Steel Quantity in Columns? Explained

Recognizing these advantages brings us to practical implementation. Here are the six main types of steel beams used in construction and their specific applications.

6 Types Of Steel Beams Used In Construction

The construction industry uses several beam profiles, each engineered for specific load conditions. Selecting the correct type is crucial for structural efficiency and project economy.

Your choice will affect the building's stability, material cost, and erection process. We examine the most common beam types below:

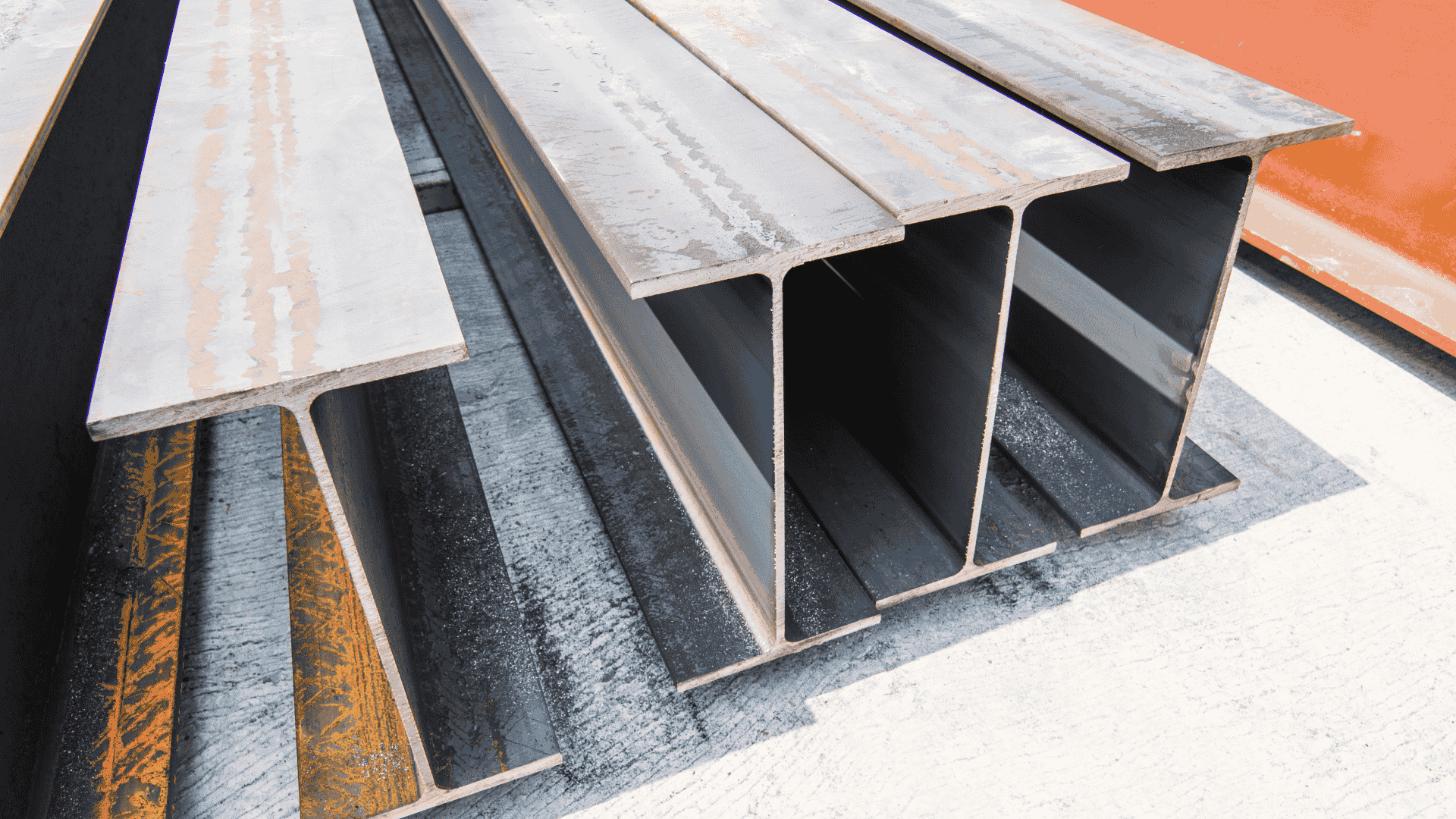

1. I-Beams

I-beams feature a vertical web with two horizontal flanges, forming an "I" shape. This design provides excellent load-bearing capacity with minimal weight.

-

What makes it a good choice: Their profile offers great strength for their weight, making them cost-effective for many applications.

-

Best for: Medium-span applications like floor joists, cross-sections, and as primary framework elements.

2. H-Beams

H-beams have a wider flange than I-beams, creating a more blocky "H" profile. They often have thicker webs and flanges, providing superior strength.

-

What makes it a good choice: They can support heavier loads over longer spans compared to standard I-beams.

-

Best for: Load-bearing columns and heavy-duty applications in multi-storey buildings and industrial structures.

3. Channels (C-Beams)

Channels have a C-shaped cross-section with a single web and two flanges. They provide good strength where mounting on a flat surface is needed.

-

What makes it a good choice: Its shape allows for easy attachment to other surfaces and structures.

-

Best for: Support frames, vehicle beds, building ledges, and as bracing elements in structural frameworks.

4. T-Beams

A T-beam resembles the letter "T", formed by a web and a single flange. This shape provides strength in one direction for specific support roles.

-

What makes it a good choice: They are ideal where a supporting ledge is required, such as in composite concrete and steel structures.

-

Best for: Supporting precast concrete floors, as reinforcement within concrete slabs, and in bridge decks.

5. Parallel Flange Channel (PFC) Beams

PFC beams are C-sections with parallel inner and outer flange faces. This offers a consistent bearing surface for easier connections.

-

What makes it a good choice: Their parallel flanges simplify connection design and fabrication with other steel members.

-

Best for: Structural lintels, wall supports, and purlins in warehouse and industrial building roofs.

6. Angle Beams (L-Shaped)

Angle beams have an L-shaped cross-section with two legs of equal or unequal length. They are versatile for providing edge reinforcement and bracing. What makes it a good choice: They are highly versatile for creating frames, shelves, and providing structural bracing. Best for: Bracing between steel columns, supporting lightweight structures, and framing for doors and windows. Also read: Diameter of Steel Bars: Sizes, Pricing & Buying Guide Understanding beam types is only part of the selection process. Proper specification requires knowledge of standard sizes and dimensional parameters. Selecting a beam requires precise knowledge of its physical dimensions and properties. Standardised sizes ensure compatibility and structural reliability across projects. Below is an outline of the common size ranges for universal beams and columns. Use this data for initial planning and discussions with your structural engineer. Beam Type Height/Width Length Depth Thickness I-Beam 100mm – 600mm 6m – 12m 100mm – 600mm 5mm – 20mm H-Beam Up to 600mm 6m – 12m Up to 600mm Up to 40mm C-Beam 50mm – 400mm 6m – 12m 80mm – 400mm 4.5mm – 17mm T-Beam 75mm – 300mm 6m – 12m 75mm – 300mm 4mm – 15mm PFC Beam 80mm – 400mm 6m – 12m 80mm – 400mm 5mm – 18mm Angle Beam 20mm – 200mm 6m – 12m 20mm – 200mm 3mm – 25mm Size specifications lead to questions about production methods. The manufacturing process directly impacts beam quality and performance characteristics. Most structural beams are created through hot-rolling, a high-temperature forming process. This method determines the beam's grain structure and final mechanical properties. Understanding the manufacturing process helps you appreciate the quality behind the product. Here is a breakdown of the primary method: Hot-Rolling Process: Heated steel billets are passed through rollers to form beam shapes. This enhances the steel's strength and creates consistent structural properties. Laser Welding: Custom beams are created by welding steel plates together with precision. This method allows for non-standard sizes and specialised beam configurations. Quality Control Testing: Finished beams undergo ultrasonic and visual inspection for defects. This ensures each beam meets required strength and dimensional standards. Surface Treatment: Beams receive protective coatings to prevent corrosion during storage. This maintains material quality before installation on your construction site. Understanding how beams are made helps explain their real-world uses. These applications demonstrate how different beam types serve specific construction needs. Steel beams serve as the backbone for virtually every type of modern structure. Their application directly correlates to the scale and function of the building. Recognising these applications helps you specify the correct beam for your project type. Here are their primary uses: 1. High-Rise and Multi-Storey Buildings

Steel beams provide the necessary strength for vertical columns and horizontal floor supports. They allow for fast erection and flexible interior space planning in urban projects across Andhra Pradesh, Telangana or Karnataka. This enables the construction of taller, more resilient buildings with shorter project timelines. 2. Industrial Sheds and Warehouses

In these structures, beams form the primary framework and support the roofing system. Their long-span capabilities create the large, open floor spaces required for industrial use. This application provides cost-effective, column-free interiors for manufacturing and storage. 3. Bridge Construction and Infrastructure

Beams are the primary components in girder bridges, supporting the deck and live loads. Their ability to handle dynamic and heavy loads makes them ideal for road and rail bridges. This ensures the durability and load capacity required for critical public infrastructure projects. Also read: Planning Steel Purchase? Check 10 mm Rod Weight & Bars per Bundle Seeing these applications highlights the importance of proper selection. Several key factors must be considered when choosing beams for a specific project. Selecting the appropriate beam involves a careful analysis of technical and practical factors. A methodical approach prevents over-engineering and controls project costs. Your decision impacts material expenditure, structural safety, and construction efficiency. Consider these key elements during the specification process: 1. Analyse the Load and Span Requirements

The beam must safely support the dead load and anticipated live loads over its entire span. Your structural engineer will calculate the required section modulus and moment of inertia. This technical analysis is the non-negotiable foundation for ensuring structural safety and compliance. 2. Consider the Connection and Fabrication Needs

The beam's shape must allow for straightforward connections to columns and other members. Complex connections increase fabrication time and labour costs on site. Simplifying connections speeds up the erection process and improves overall buildability. 3. Evaluate Material Availability and Project Timeline

Common beam sections like standard I-beams are typically more readily available. Special sections may require longer lead times, which could affect your project schedule. Sourcing readily available sections helps you maintain your construction timeline and budget. Selecting the right beam is one challenge; sourcing it is another. SteelonCall addresses common sourcing obstacles with a streamlined online marketplace. Finding the right steel beams in the required quantities is often a challenge. Builders frequently face delays, inconsistent quality, and unclear pricing from local dealers. SteelonCalloffers a dependable solution for your structural steel needs. Our online marketplace connects you directly to verified manufacturers and mills. Verified Quality Materials: We supply structural beams from trusted sources, ensuring they meet relevant Indian standards for your project's safety. Direct Manufacturer Access: Source MS beams, channels, and columns directly, ensuring authentic material and competitive, transparent pricing. Wide Selection and Specifications: Choose from a comprehensive range of sections and sizes, including universal beams and columns for any design. Reliable Regional Delivery: Our managed logistics ensure your structural steel reaches your site in Andhra Pradesh, Telangana, or Karnataka on schedule. This integrated approach provides a dependable and efficient supply chain for your construction projects. Selecting the right steel beam is a critical decision that influences your project's structural integrity and cost. From versatile I-beams to robust H-beams, each type serves a distinct purpose in construction. Your informed choice ensures the safety, efficiency, and success of the build. SteelonCallsupports this process with direct access to quality-assured structural steel sections through its online marketplace. We connect you to a verified network for a transparent and reliable buying experience. Browse our catalogue of wide parallel flange beams to find the right sections for your project. Check out our live prices here. Q. What is the most common beam used in construction?

The I-beam is the most common type due to its excellent strength-to-weight ratio. Its distinctive shape provides maximum stiffness with minimal material use. You will find it frequently used as a primary support in floors and roofs. Q. How do I choose a steel beam size?

You must consult a structural engineer to calculate the loads and spans for your project. They will determine the required section modulus and moment of inertia. This analysis ensures the selected beam size can safely support all anticipated weights. Q. What is the difference between an H-beam and an I-beam?

H-beams have wider, thicker flanges and are often used as columns or for heavier loads. I-beams have tapered, narrower flanges and are typically used as cross-sectional support beams. The H-beam generally handles greater stress in all directions. Q. Are steel beams resistant to fire?

Steel beams lose strength at high temperatures and require fireproofing for most building codes. They are typically protected with fire-resistant coatings, boards, or concrete encasement. This protection maintains the beam's integrity for a specified period during a fire. Q. Where can I buy steel beams for construction?

You can buy steel beams directly from verified manufacturers and suppliers on SteelonCall, India’s trusted online steel marketplace. It ensures quality materials, transparent pricing, and reliable delivery for your project. The platform simplifies steel sourcing for builders across South India.

Steel Beam Sizes And Specifications

Also read: 12mm Steel Bar Length Chart: Check Vizag Steel 12mm Rod DetailsHow Are Steel Beams Manufactured

Applications of Steel Beams In Construction

How To Choose The Right Steel Beam For Your Site

Simplify Your Steel Beam Procurement With SteelonCall

Conclusion

FAQs