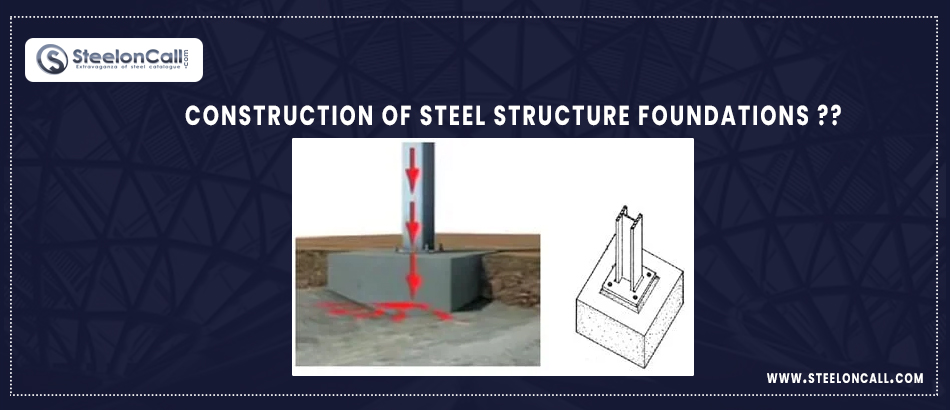

Construction of Steel Structure Foundations

The structural steel construction involves a framework that includes two principal factors, and they are like fabrication and erection. Fabrication consists of the handling of crude materials to shape the completed individuals from the structure. Erection incorporates all rigging, hoisting, or lifting of members to their appropriate places in the construction and making the completed associations between individuals.

Some of the factors for the construction of steel structures foundations:

- Structural steel is steel construction material created with a particular shape and synthetic organization to suit an undertaking's appropriate determinations. Depending on each relevant detail, the steel Structure segments may have different shapes, sizes, and measures made by hot or cold moving. Others are made by welding together level or twisted plates.

- Basic shapes incorporate the I-pillar, channels, angles, and plate. Structural requirements include a description of the heap's structures that must help, starting with the consistent ordinary piles of building substance forced by gravity and stretching out to the less continuous, however progressively extraordinary loadings of wind and earthquake forces.

- Security factors for materials are indicated to take into consideration incidental over-burdening and slips by value control.

- Economic considerations are additionally reflected; for instance, structures must perform well under typical gravity loads. However, no code requires a structure to oppose direct presentation to the breeze and low-pressure impacts of a tornado, for its expense would be restrictive.

CONSTRUCTION OF STEEL FRAME STRUCTURE FOUNDATIONS:

Steel is a significant structural material in these building's structures. It is a solid and firm material but then generally cheap, and it very well may be immediately manufactured and raised, which spares development time. Even though steel Structure is noncombustible, it begins to lose quality when warmed above 400° c (750° f). Construction laws expect it to be insulated in most multistory structures; in little and low-danger structures, in any case, it very well may be left unprotected. One more of the life-wellbeing components in these structures is the imperviousness to fire prerequisites for building materials. These incorporate the utilization of cementitious insulating or protection to basic steel frames—the fire-resistive development of the fenced-in areas around exits. The fire spread evaluations of finish materials, for example, covering and divider covers, and the utilization of such innate heatproof materials as reinforced concrete and overwhelming timber. The fire-resistive appraisals of different development materials and gatherings are built up by research center fire tests.

A specific construction team typically executes the construction of a building structure. It usually is separate from the design team, although some enormous associations may consolidate the two capacities. The development group is going by a planning association, frequently called a general contractual worker. It assumes the essential liability for executing the structure and signs an agreement to do as such with the structure client. The expense of the deal concurs a single amount. However, cost-in addition to charge contracts is at times utilized on massive undertakings. The development starts before the agreement archives are finished, and the structure extension isn't wholly characterized. The general temporary worker may do a portion of the genuine work on the structure, notwithstanding its planning job. The rest of the work is compeleted by gathering of claims to fame subcontractors who are under agreement with the general contractual worker. Every subcontractor gives and introduces at least one of the structure frameworks, e.G., the auxiliary or electrical framework. The subcontractors thus purchase the framework segments from the makers. During the development procedure, the planning group keeps on going about as the proprietor's agent. It ensures that the executed structure fits in with the agreement reports and that the frameworks and segments fulfill the predetermined guidelines of value and execution.

Steel frame structures construction used in the following applications and environments:

- Industrial buildings: steel structure can make enormous spaces for assembling, stockpiling, and creation purposes, at a financially cost-effective price.

- Warehouse buildings: warehouses likewise require substantial open spaces and a solid structure. It makes steel outline structures perfect as it gives a stable and enduring structure for this reason.

- Residential buildings: steel frame houses are getting amazingly mainstream in some zones, because of the numerous focal points offered by steel frame structures.

- Temporary buildings: if you require a temporary building, a steel frame structure is perfect. Steel structure are raised quicker than traditional structures and can dismantle effectively when not, at this point required. Brief structures are frequently utilized for schools, places of worship, and places of business to give some examples.

Steel structure can be utilized to make complex types of development, monetarily, and without any difficulty.