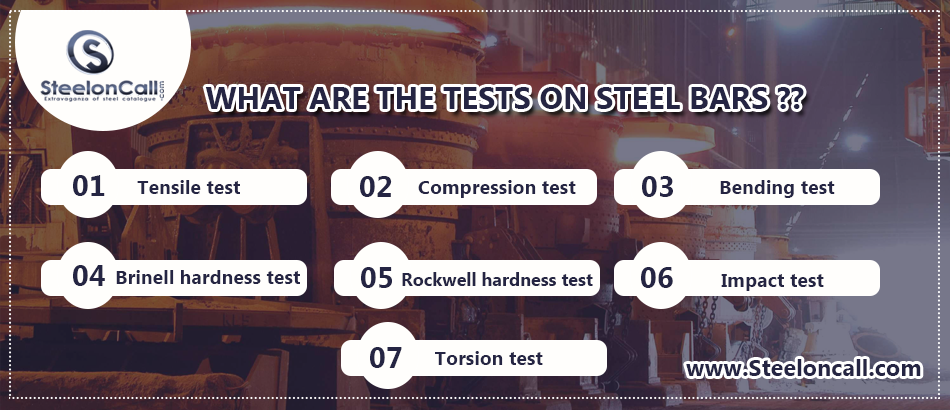

What are the tests on steel bars

Material testing of a steel bar is crucial, and it is similarly put under examination to recognize its various specific uses. It involves the estimation of attributes and behavior of substances like metals, plastics, and ceramics under varying conditions. Steel bar reinforcement is essential to inspect and test periodically to decide its adequacy. The tests on steel bars must include

- Tensile test

- Compression test

- Bending test

- Brinell hardness test

- Rockwell hardness test

- Impact test

- Torsion test

Steeloncall briefly explains the different tests conducted on steel bars below:

TENSILE TEST:

This tensile test process is one of the crucial tests of steel bars. A tension test of steel materials is a damaging procedure that gives data about the elasticity, tensile strength, and yield strength of the sample. This tensile test is done to decide how the material responds when you apply a force to it. Generally, by pulling the metal, one has to recognize the material's rigidity and yield quality, just as the amount will extend. Tension test is the essential criterion where one presents a steel bar test to tension, which is under control until the failure stage.

COMPRESSION TEST:

The compressive quality is the most extreme compressive stress a material is equipped for withstanding without crack. Brittle materials crack during testing and have a definite compressive strength value. Their level of bending during testing dictates the compressive strength of flexible materials. Compressive quality test, mechanical test estimating the most considerable measure of compressive burden a material can tolerate before breaking.

BENDING TEST

Bend testing on steel bars takes into consideration that materials resistance to fracture, ductility, fracture strength, and bend strength. These qualities can be utilized to decide if a piece of equipment will fail under pressure and are essential in any construction procedure, including plastic materials loaded with bending forces. If an article starts to break or cracks during a bend test, it is valid to accept that the content will fail under a similar in any application, which may prompt to catastrophic failure.

BRINELL HARDNESS TEST

The Brinell test was the first broadly utilized standardized steel hardness test. It requires a large test piece and leaves a considerable space; hence, it is constrained in its usefulness. Brinelling has come to mean the permanent indentation of any hard surface. This Brinell hardness test involves a large, heavy ball, which is pushed against steel at a predetermined level of force.

ROCKWELL HARDNESS TEST

The Rockwell test is commonly simpler to perform, and more exact than different kinds of hardness testing techniques. The Rockwell steel bars test strategy is utilized on all sorts of metals, except for in conditions where the test metal structure or surface conditions would present an excessive amount of varieties; where the indentations would be unreasonably enormous for the application; or where the sample size or test shape forbids using.

IMPACT TEST

The impact test decides the amount of energy consumed by a material during the crack. This absorbed energy is a measure of a given material's strength and goes about as a device to consider temperature-dependent weak, flexible progress. It is to decide if the content is fragile or malleable. Impact Testing of steel bars is performed to determine the active opposition or durability of materials by figuring the measure of energy absorbed during fracture. The impact test is performed at different temperatures to reveal any consequences on impact energy. These services give test results that can help evaluate the suitability of a material for a specific application and predict its expected service life.

TORSION TEST

The reason for a torsion test is to decide the behavior a material or analysis shows when turned or under torsional forces because of applied moments that cause shear stress about the axis. Measurable values include the modulus of ductility, ultimate shear strength, elasticity in shear modulus of rupture in shear, yield shear strength, and tensional fatigue life. These values are similar but not the same as those measured by a tensile test. They are significant in assembling as they might be utilized to simulate the service conditions, check the item's quality and structure, and guarantee that it was made expertly.

The steel bars hardness tests do measure hardness in the index but units. Since all of the steel hardness tests are so normal, the list is given as a number followed to indicate the test method.