What is the difference between an H-beam and I-beam?

H-beam is a structural beam made of moved steel. It is fantastically solid. It gets its name since it would appear that a capital H over its cross-segment. With certain structures where weight and force on a wall may represent a basic issue, the I-beam might be better since it is frequently lighter. I-beams have an assortment of significant uses in the basic steel development industry. They are frequently utilized as basic help supports, or the fundamental structure, in structures. Steel I-beams guarantee a structure's uprightness with tireless quality and backing. The huge influence of I beams diminishes the need to incorporate various help structures, setting aside time and cash, just as making the structure progressively steady. The adaptability and steadfastness of I-beam make them the desired asset to each developer. An I-pillar is made by rolling or processing steel which implies the I-beam is frequently restricted by the limit or size of the processing hardware.

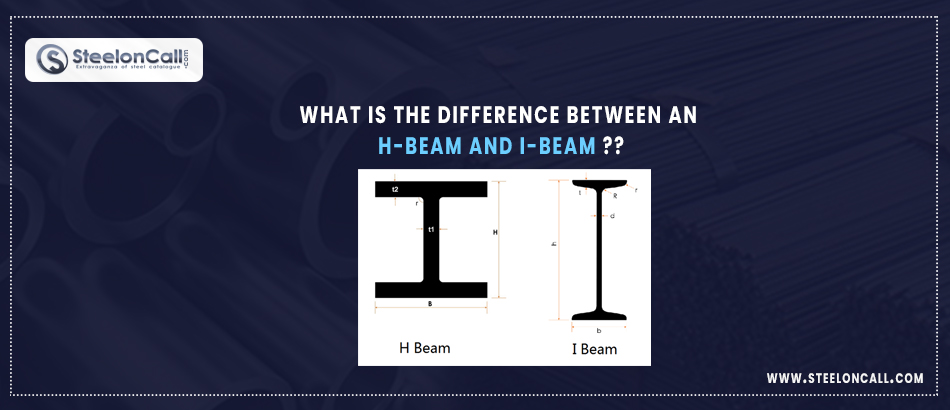

I-beam, otherwise called a universal beam, is long steel with the I-bar segment. I-beam is separated into conventional I-beam and light I-bar. It is I-beam steel. I-beam is principally isolated into a common I-bar, light I-beam and wide rib I-bar. As indicated by the stature proportion of the spine and web, it very well may be partitioned into wide, medium and thin rib I-bars. The initial two details are 10-60, that is, the comparing stature is 10 cm-60 cm. At a similar stature, the light I-bar has a limited rib, slim web and lightweight. Wide rib I-beam, otherwise called h-beam, is portrayed by equal legs and no tendency inside the legs. It has a place with the financial area and is moved on four high all-inclusive plants, so it is additionally called widespread I-beam. Customary I-beam and light I-bar have shaped national gauges. As appeared in the name, I-bar is an "I" segment steel. The inward surface of the upper and lower ribs has a tendency of 1:6, which makes the external rib slight and the internal spine thick. Accordingly, the cross-segment attributes of the I-bar in the two fundamental planes are enormously unique, which is hard to play in the application. H-beam has twisting obstruction every which way it has been generally utilized for its solid capacity, straightforward development, cost-sparing and light structure weight. H-area steel is generally utilized in the present steel structure development. Contrasted and I-area steel, it has numerous distinctions. The first is the rib, the second is that the internal surface of the rib has no tendency, and the upper and lower surfaces are equal. The segment normal for h-bars is better than that of I-bar, channel and edge steel. The internal and external sides of the spine of h-beam are equal or near equal, and the rib closes are at right edges, so it is named equal rib I-beam. The web thickness of h-beam is littler than that of regular I-bar with a similar stature of the web, and the spine width is bigger than that of normal I-beam with similar tallness of web, so it is likewise called wide edge I-bar.

The spine of h-beam is of equivalent thickness, with a moving area and joined segment made out of 3 plates welded. The I-beam is completely moved. Because of poor creation innovation, the internal edge of the spine has a slant of 1:10. The moving of h-beam is not quite the same as that of a normal I-bar, just one lot of water is utilized. H-beam, as the name recommends, is moved steel joist with the cross-segment as the capital letter h. It is one of the most well-known and generally utilized basic steel individuals utilized in both private and business building ventures. In view of its boss' mechanical properties and better solidarity to weight proportion, they settle on the favored decision of material for mezzanines, extensions, and stages. In addition, they have wide spines that are generally utilized in private structure ventures. I-beam, as the name proposes, is an I-molded basic part with the cross-segment as the capital letter 'I'. Dissimilar to h-bars, they have slim spines which are normally smaller with tightened closes for expanded quality. This makes them great at bearing burden under direct tension. Due to their high elasticity, they are utilized in steel-surrounded structures and connections and other common undertakings.

H-beam is practical segment steel with a more enhanced cross-sectional territory of dissemination and sensible solidarity to weight proportion meaning it can give more quality per unit of weight. This makes welding of h-beam generally less complex than that of I-beam. Also, due to its more noteworthy surface zone on the cross-area, it is considered to have a high-quality proportion. Nonetheless, I-formed bars are ordinarily more profound than they're wide, which makes them very great at bearing burden under neighborhood clasping. In addition, I-bars are lighter than h-beam which implies they won't have the option to take as much power as h-beam.