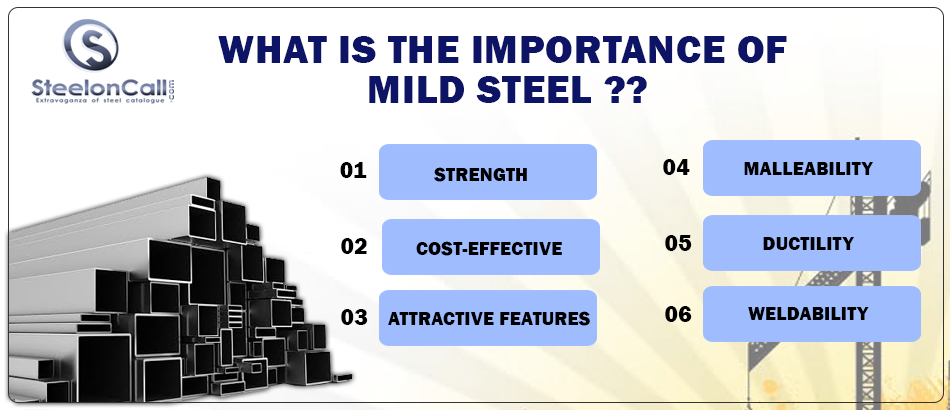

What Is The Importance Of Mild Steel

Steel is an alloy of iron, comprising 0.2% to 2.1% of carbon, as a solidifying agent. Other than carbon, numerous different metals are a piece of it. Elements like chromium, manganese, tungsten, and vanadium may also present to some extent. Other than a maximum limit of 2% carbon in the manufacture of carbon steel, the extents of manganese (1.65%), copper (0.6%) and silicon (0.6%) are fixed, while the sizes of cobalt, molybdenum, titanium, nickel, tungsten, chromium, niobium, vanadium and zirconium are not.

Mild steel containing a small percentage of carbon, stable and tight but not readily tempered. Mild steel, also otherwise called plain-carbon steel and low-carbon steel, is presently the most well-known type of steel since its price is moderately low. At the same time, it provides material properties that are satisfactory for some applications. Mild steel contains roughly 0.05–0.30% carbon making it malleable and flexible. Mild steel has a subsequently less tensile strength; however, it is modest and straightforward to frame; surface hardness can be expanded through carburizing.

Some of the unique features of mild steel are as follows:

Strength: Because of the low measure of soft carbon steel contains, it is stable. Mild steel has high protection from breakage. Mild steel, as opposed to more top carbon steels, is quite malleable, even when cold. This implies it has high tensile and impact strength. More top carbon steels generally break or split under pressure, while mild steel bends or deforms.

Cost-Effective: The most affordable of all steel types are mild steel. Many everyday objects are made utilizing mild steel, including motorcycle frames and a great deal of cookware and auto-mobile chassis. The mystery behind its affordability is its carbon content, ranging somewhere in the range of 0.16% and 0.29%. This middle point of the carbon count range means it's sufficient for some employments without being expensively tensile. At the point when it's required in bulky orders, it is very well may be delivered all at once with a far reduced cost than different steels; with results, one surely can contend.

Attractive Features: The most crucial feature of mild steel is that it can be formed into any ideal desired shape. It is effortless to frame low carbon items by pressing and pouring it into an essential way. It is one of the most flexible materials as it very well may be mounted into various pipes, stampings, rivets, etc.

Malleability refers to the capacity of a material to resist cracking regardless of whether it is twisted or bent. The malleability of mild steel additionally enables it to be folded or beaten into thin sheets, according to the required usage type.

Ductility: Ductility is a measure of how a lot of a material can be plastically twisted by prolongation without crack. Materials that are highly solid in such manner can go over 15% before they are permanently deformed and unable to return to their unique shape. Mild steel shares excellent organization in such way to copper and thermoplastics, ready to twist, extend, and generally have large forces applied to it, making it simpler to frame, shape and weld.

Weldability: Another gainful element of this product is weldability. This is mainly because of the low carbon substance of the metal. Manufacturers utilize more content of carbon to reinforce the metal. However, hard steel is inclined to breaks when it is welded. However, metal with low carbon content only from time to time splits, and along these lines, it tends to be welded expertly.

Typical Applications of Mild Steel

There are a few essential common areas in which mild steel might be used:

- Structural steel

- Furniture and decorations

- Signs

- Cars

- Wire

- Fencing

- Nails

- The calculated and determined average grade mild steel density is 7861.093 kg/m3. It's Young's modulus, a measure of its firmness is around 210,000 MPa.

- Mild steel has ferromagnetic properties, which make it perfect for assembling of electrical gadgets and engines. It yields itself effectively to polarization.

- Mild steel can be machined and formed effectively because of its intrinsic flexibility. It tends to be solidified with carburizing, making it the perfect material for creating a scope of customer required products.

- Mild steel is especially inclined to rust since it has a high measure of carbon. At the point when rust-free items are required individuals incline toward over mild steel

Properties Of Mild Steel

Mild steel is particularly attractive for construction because of its weldability and machinability. Because of its high quality and malleability, it is very delicate. This implies it tends to be expertly machined contrasted with harder steels. It is additionally simple to weld, both to itself and to different sorts of steel. It takes on a decent finish and is polishable. However, it can't be solidified through heat treatment processes, as higher carbon steels can. This isn't wholly a terrible thing, because harder steels are not as stable, settling on them a poor decision for construction projects.