How to Check the Grade of Steel for Construction Projects

Steel problems rarely announce themselves early. They surface when concrete is already poured or fabrication is underway. A mismatched steel grade can halt work, trigger rechecks, and force uncomfortable conversations.

The pressure is worse when timelines are tight, and deliveries arrive late in the day. At that point, rejecting material feels risky, but accepting it feels worse. This is why knowing how to check the grade of steel matters before it goes into the structure, not as a lab exercise, but as a practical safeguard for your schedule and accountability.

This blog breaks down simple, reliable ways to verify steel grade at the right moments. The goal is clarity before commitment, fewer surprises on site, and smoother progress where every decision holds.

Key Takeaways:

-

Ensure the Mill Test Certificate (MTC) and heat numbers match before dispatch or unloading to avoid mismatched steel.

-

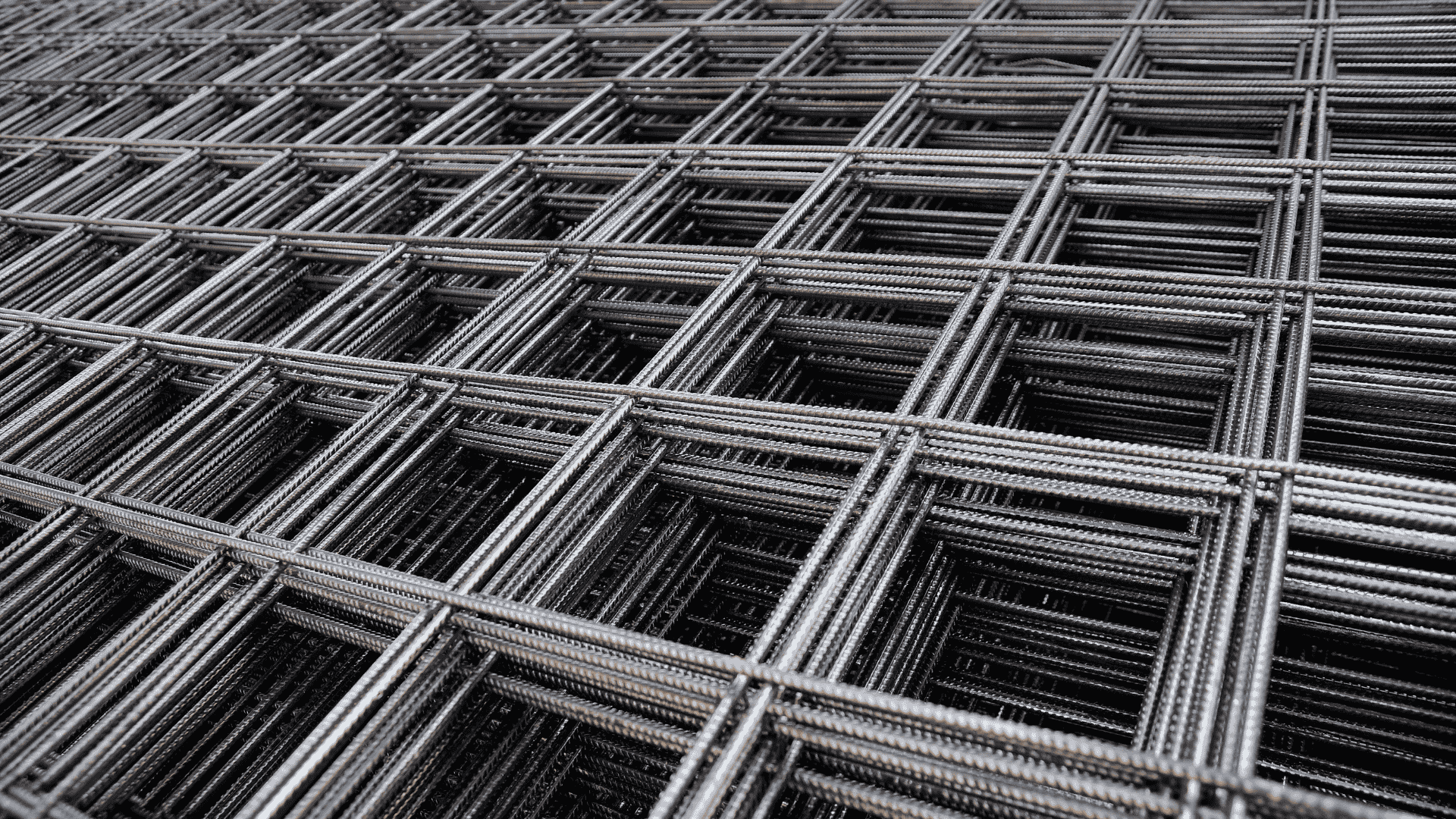

Check for clear grade markings, consistent manufacturer embossing, and no visible defects during unloading.

-

Use bend, re-bend, and spark tests to identify steel issues before fabrication begins.

-

For high-rise or heavy-load structures, insist on lab tests to confirm steel grade and mechanical properties.

-

Grade checks confirm steel type, while quality checks ensure reliable performance during construction. Both must be done at different stages.

Good Quality Steel vs. Bad Quality Steel

Choosing the right steel is essential for structural integrity. Good quality steel meets industry standards, has consistent properties, and is traceable from supplier to final product. It’s certified, free from defects, and performs well in tests. Bad quality steel, however, often lacks proper certification, contains impurities, and can fail physical tests, leading to risks in construction.

Here’s a more comprehensive comparison of good and bad quality steel:

|

Aspect |

Good Quality Steel |

Bad Quality Steel |

|

Certification |

Proper Mill Test Certificate (MTC), meets recognized standards (e.g., ASTM, IS) |

Lacks a valid MTC, fake or inconsistent certification, and no traceable standards |

|

Chemical Composition |

Consistent alloy content, within specified limits (e.g., carbon, manganese, chromium) |

Impurities, incorrect alloy ratios, or off-spec composition affecting strength |

|

Mechanical Properties |

Meets required tensile strength, yield strength, ductility, and fatigue resistance |

Weak mechanical properties, brittle, low tensile strength, poor ductility |

|

Surface & Appearance |

Smooth, uniform surface; free from cracks, rust, and defects |

Visible rust, surface roughness, cracks, delamination, and other defects |

|

Field Test Results |

Passes field tests (bend, re-bend, spark tests) with no premature failure |

Fails basic tests, such as cracking in bend tests or inconsistent spark patterns |

|

Markings & Traceability |

Clear, consistent grade, heat number, and supplier markings for full traceability |

Inconsistent or absent markings, difficult to trace origin or batch |

|

Batch Consistency |

Uniform appearance and quality across the entire batch |

Variations in section sizes, diameters, or rib patterns within the same batch |

By understanding these differences, you can better assess the steel you're working with. Now, let's move on to practical ways you can check the steel grade before use to ensure its quality.

Practical Ways to Check Steel Grade Before Use

Checking steel grade works best when handled through a fixed sequence that controls risk early and prevents corrective action after work has already started.

Each stage addresses a different failure point, and skipping any step usually shifts the problem to site execution, where delays and disputes increase sharply.

Here are the four checks you should follow in sequence before steel is approved for cutting, bending, or casting work:

Verify Steel Grade Through Supplier Documents

Document verification acts as the first control gate and confirms whether the supplied steel matches the grade, standard, and source approved during procurement.

Key document checks you should complete at this stage include:

-

Mill Test Certificate (MTC): Confirm the certificate clearly states the steel grade, IS standard, manufacturer name, and test compliance without corrections or handwritten changes.

-

Heat number traceability: Match the heat number shown on the certificate with the heat number listed for the specific batch being dispatched.

-

Quantity and size confirmation: Ensure diameters, section sizes, and quantities mentioned on documents fully match the purchase order and delivery challan.

-

Single-batch clarity: Verify that one certificate covers one identifiable batch, not multiple unrelated deliveries grouped together.

If any document detail appears unclear, material acceptance should pause before dispatch or unloading proceeds.

Conduct On-Site Visual Checks to Catch Grade Issues Early

Visual inspection during unloading helps you identify obvious mismatches at the earliest point, when rejection or correction remains practical.

Visual points you should confirm at the site include:

-

Grade marking visibility: Check that grade markings such as 500D or 550D are clearly visible on bars, tags, or stamped sections.

-

Manufacturer embossing consistency: Confirm that all bundles carry identical manufacturer markings, with no variation in logos or embossing styles.

-

Bundle tag condition: Ensure tags remain intact, readable, and consistent with delivery documentation provided during dispatch.

-

Physical uniformity: Observe diameter, rib pattern, or section profile consistency within the same batch to detect supply variation.

-

Check Corrosion Resistance: During the visual inspection, observe any obvious signs of corrosion or surface damage that might indicate poor material quality or inadequate corrosion resistance.

Visual checks highlight warning signs but should never be treated as final grade confirmation.

Perform Simple Field Tests to Confirm Steel Grade at Site

Field tests support acceptance decisions by revealing abnormal material behaviour before steel enters fabrication or reinforcement work.

Standard site-level tests you can rely on:

-

Bend test: This test checks ductility required for RCC work, where visible cracking during bending signals possible grade issues.

-

Re-bend test: Used when extra assurance is required, this test highlights brittleness that may appear after initial deformation.

-

Spark test: Common in fabrication yards, this test helps identify obvious mismatches between supplied material and intended application.

-

File check: This check highlights inconsistency within a batch rather than confirming the exact steel grade.

These tests support judgment but cannot replace document verification or laboratory confirmation.

Conduct Lab Testing When Site or Approval Risk Is High

Laboratory testing becomes essential when the risk of project delays or approval setbacks is high. Without proper verification, approvals can be delayed, which could impact project timelines and execution. In these cases, the cost and time of lab testing are far outweighed by the potential consequences of not securing the necessary approvals.

Situations where you should insist on lab testing include:

-

High-rise or critical structures: Projects involving heavy loads or significant safety exposure require formal confirmation before steel is incorporated into the structure.

-

Consultant or authority-controlled projects: Many approvals depend on certified reports, making laboratory testing mandatory for material acceptance.

-

Structural steel and fabrication work: Welding, bolting, and load transfer require confirmed mechanical properties before fabrication begins.

-

Unclear or inconsistent checks: Any mismatch in documents, markings, or site tests should trigger laboratory confirmation without delay.

-

Check Tensile Strength: For projects where load-bearing capacity is critical, verifying tensile strength through lab tests ensures the steel meets the necessary performance standards under stress and strain conditions.

By adhering to this process, you ensure that steel grade verification is controlled, predictable, and aligned with project execution requirements, ultimately minimizing the risk of delays due to approval holdups. To apply the proper control at the right time, you need to clearly separate grade verification from material behaviour checks.

Also Read:Different Grades Of TMT Steel Bars

Grade Verification vs Quality Testing: What Buyers Must Know

Many buyers assume that once steel grade is verified, material performance is assured, but this assumption often causes confusion during execution. Grade checks and quality checks serve different purposes, and treating them as the same control creates blind spots during acceptance and use.

The table below separates grade checks from quality checks so you can apply each control correctly at the right stage.

|

Aspect |

Grade Check |

Quality Check |

|

Primary focus |

Confirms the supplied steel matches the specified grade and standard mentioned in orders and approvals |

Confirms the steel behaves consistently during bending, welding, and load application |

|

Typical inputs |

Mill Test Certificate, heat numbers, grade markings, and supplier documents |

Site tests, laboratory reports, and physical behaviour during use |

|

Buyer objective |

Ensure the correct grade was supplied as ordered |

Ensure the steel performs reliably during construction or fabrication |

|

When it happens |

Before acceptance, unloading, or approval for use |

During initial use, batch checks, or phased execution |

|

Risk if skipped |

The wrong grade enters the structure or fabrication |

Cracks, failures, or inconsistent behaviour during work |

|

Common misconception |

Passing documents means steel is fully safe for use |

Good site behaviour means grade compliance is guaranteed |

Understanding this difference helps you apply the right control at the right moment, reducing surprises after work has already started. If steel grade issues keep repeating, the cause usually lies in buying habits rather than site inspection steps.

Also Read: Online Steel Selling Providers: Quality Steel at Competitive Prices

Common Steel Buying Mistakes That Lead to Grade Issues

Most steel grade problems do not begin at the site but originate during buying decisions made under time pressure or unclear specifications.

These mistakes often remain hidden until work starts, when correction leads to delays, disputes, and cost exposure.

Here are the most common buying mistakes that repeatedly lead to steel grade issues across construction and fabrication projects:

-

Buying only on the lowest price: Buying only on the lowest price without locking grade and brand allows substitutions that surface only after unloading or processing.

-

Unclear purchase orders: Placing purchase orders without clearly stating grade and IS standard leaves room for interpretation during dispatch and delivery.

-

Not locking the steel brand: Specifying only the grade (e.g., 500D) without the brand can lead to different brands being dispatched, causing variations in steel behavior and traceability issues.

-

Mixed brands or batches: Accepting mixed brands or batches on one site breaks traceability and causes inconsistent behaviour during bending or fabrication work.

-

Skipping checks at unloading: Skipping document checks during unloading leads to acceptance of material before grade confirmation is completed.

-

Verbal assurances over proof: Relying on verbal assurances instead of written certificates removes proof during disputes and weakens buyer control.

-

Reusing certificates: Using one certificate for multiple deliveries hides batch differences and makes later verification a difficult process.

-

Late testing decisions: Delaying testing until work begins shifts discovery to a stage where rework and rejection cause serious schedule impact.

Avoiding these mistakes requires controlling grade risk before steel leaves the supplier, not after it reaches the site.

Also Read: Your Ultimate Destination for Quality Steel Plates

How You Can Reduce Steel Grade Risk at Source

If you want to avoid grade issues, it’s crucial to control risk early, before the steel moves from the supplier’s yard to the construction or fabrication site. By focusing on clarity, traceability, and discipline right from the sourcing stage, you can take corrective action easily and limit cost exposure.

Here are the practices you can follow to reduce steel grade risk before the material reaches the site:

-

Clear enquiry specifications: Specify the grade, IS standard, and acceptable brands clearly when making inquiries. This eliminates ambiguity during pricing and dispatch.

-

Verified source selection: Choose suppliers with direct manufacturer access. This improves traceability and reduces the risk of mixed lots or substituted grades.

-

Single brand discipline: Stick to one approved brand per grade across a project. This helps avoid variations in behavior during bending, welding, or structural assembly.

-

Advance document confirmation: Confirm certificates and heat numbers before dispatch. This ensures that incorrect material never reaches the unloading points.

-

Batch-level tracking: Track steel by batch across phased deliveries. This lets you detect inconsistencies early and prevent the same mistake from being repeated.

-

Price clarity before booking: Establish clear pricing before booking. This reduces pressure to make last-minute compromises that could affect grade or brand control.

-

Procurement and site coordination: Ensure close coordination between procurement and site teams. This ensures acceptance decisions follow approvals rather than being driven by urgency.

Applying these practices consistently becomes simpler when the sourcing process itself supports grade clarity and traceability.

How SteelonCall Supports Grade-Sure Steel Buying

Steel grade checks work best when the source itself is controlled. Many site issues begin earlier, during pricing, vendor selection, or dispatch planning. SteelonCall's digital marketplace addresses these gaps by giving you clarity before steel moves, not after it reaches the site.

Here’s how SteelonCall helps you reduce grade risk and supply friction:

-

Upfront pricing: SteelonCall is the only platform where GST-inclusive steel prices are visible before booking, ensuring you know the exact payable amount without later additions.

-

Verified sellers only: All listed vendors are trusted, which reduces the risk of mixed lots, wrong grades, or unclear material history at the site.

-

Price match assurance: If a verified lower quote is found, the rate is matched to help maintain cost stability across repeat orders.

-

Planned dispatch: Dispatch is scheduled in advance, reducing waiting time and keeping fabrication or construction work on track.

-

Known steel brands: Material is supplied from recognised brands, giving clear grade confidence for plates, beams, and structural sections.

-

Flexible payments: Multiple payment options support smoother cash flow for large or ongoing steel requirements.

-

Quick support access: Fast assistance during booking or delivery tracking helps resolve doubts early and avoid work stoppages.

If you want structured supply and clear guidance for MS plates and other steel needs, reach out to SteelonCall and speak with our experts.

Conclusion

Checking the grade of steel is not a formality. It is a control step that protects drawings, approvals, timelines, and accountability. When grade verification is done early and done right, you can avoid rework, disputes, and site stoppages that are hard to recover from later.

The most reliable results come from combining clear specifications, document checks, site inspections, and testing where required. This approach keeps procurement predictable and ensures the steel used on site matches what was planned, approved, and paid for.

If you want clearer pricing, confirmed grades, and structured steel supply without last-minute surprises, speak with our experts today.

FAQs

1. Can steel grade change within the same brand across different deliveries?

Yes, steel grade consistency can vary between batches, even within the same brand, especially when supplies come from different production heats. This is why you should treat each delivery separately and confirm batch details instead of assuming uniformity across orders.

2. Is it acceptable to store steel on site before grade verification is complete?

Storing steel before verification increases the chance of mix-ups, especially on active sites with multiple materials moving daily. Once stored with approved stock, segregation becomes difficult, and accidental usage risk increases.

3. Do consultants usually accept steel without third-party test reports?

Acceptance depends on project specifications and risk level, as some consultants rely on documents and site checks for routine work. For critical structures, authorities often expect lab reports to support approval and future accountability.

4. How should rejected steel be handled to avoid future confusion?

Rejected steel should be clearly marked, physically separated from approved material, and recorded in site logs or registers. This prevents accidental use and avoids disputes during later inspections or audits.

5. Does weather exposure affect steel grade verification results?

Weather exposure does not change steel grade, but prolonged exposure can affect surface condition and readability of markings. This makes visual inspection harder and may delay acceptance decisions if the documentation is not clear.