Mild Steel Applications in Fabrication: Uses, Advantages & Processes

In every fabrication project, the choice of material directly affects cost, production time, and long-term performance. Engineers and procurement teams need materials that are easy to work with, consistent in quality, and economical for bulk use.

Mild steel checks all these boxes with its strength, flexibility, and excellent weldability. It enables fabricators to create reliable frames, panels, machinery parts, and structural components without inflating production costs.

With India using over 136 million tonnes of finished steel in FY24 (IBEF), much of it in fabrication and construction, mild steel remains the practical choice for projects of all sizes.

Understanding its properties, advantages, and best applications ensures your fabrication work stays efficient, durable, and within budget.

Chemical, Physical, and Mechanical Properties of Mild Steel

Mild steel, also called low-carbon steel, is a highly versatile material widely used in construction, fabrication, and industrial projects.

Its suitability comes from a combination of chemical composition, physical traits, and mechanical behavior, each of which directly impacts how it performs in real-world applications.

1. Chemical Properties

Knowing the chemical makeup helps builders and fabricators understand why mild steel is ductile, weldable, and cost-effective for structural and fabrication needs.

-

Carbon Content: Typically 0.16–0.29%, providing ductility and weldability.

-

Manganese: Up to 1.03%, improving toughness and hardness.

-

Silicon: Up to 0.40%, contributing to strength and deoxidation.

-

Phosphorus and Sulfur: Usually below 0.04–0.05%, preventing brittleness.

2. Physical Properties

Physical traits determine how mild steel behaves on-site and during fabrication, from weight and handling to heat tolerance.

-

Density: ~7.85 g/cm³, standard for structural calculations.

-

Melting Point: ~1450–1520°C, suitable for welding and fabrication.

-

Magnetic Properties: Ferromagnetic, useful for alignment and industrial applications.

-

Appearance: Grayish metallic; surface can be hot-rolled or cold-rolled depending on the finish.

3. Mechanical Properties

Mechanical properties dictate how mild steel performs under stress, load, and shaping, making it reliable for construction and fabrication.

-

Tensile Strength: ~400–550 MPa, ensuring structural reliability.

-

Yield Strength: ~250 MPa, preventing permanent deformation under load.

-

Elongation at Break: ~20–23%, allowing bending and forming without cracking.

-

Modulus of Elasticity: ~200 GPa, indicating stiffness.

-

Brinell Hardness: ~120–140 HB, balancing machinability and durability.

These mechanical properties make mild steel a reliable choice for industrial fabrication, from frames and panels to pipes and machinery components.

Mild steel's combination of low carbon content, controlled alloying, and favorable mechanical properties ensures that it is easy to fabricate, cost-effective, and versatile for industrial and manufacturing applications.

Core Applications of Mild Steel in Fabrication

Mild steel is widely used in fabrication due to its strength, flexibility, and ease of machining. It adapts to a variety of industrial and structural needs:

-

Steel Frame Buildings: Provide strong and durable structural frameworks for industrial and commercial constructions.

-

Gates and Fencing: Offers reliable support and flexibility for security and boundary solutions.

-

Pipelines: Ensures robust, corrosion-resistant conduits for fluid and gas transport.

-

Machinery Parts: Used for shafts, rods, rollers, and components requiring precision and strength.

-

Enclosures and Ducting: Forms protective casings and channels for equipment, air, and fluid systems.

-

Brackets and Modular Supports: Provide versatile and sturdy support structures for industrial setups.

Mild steel's strength, flexibility, and machinability make it ideal for a wide range of fabrication applications.

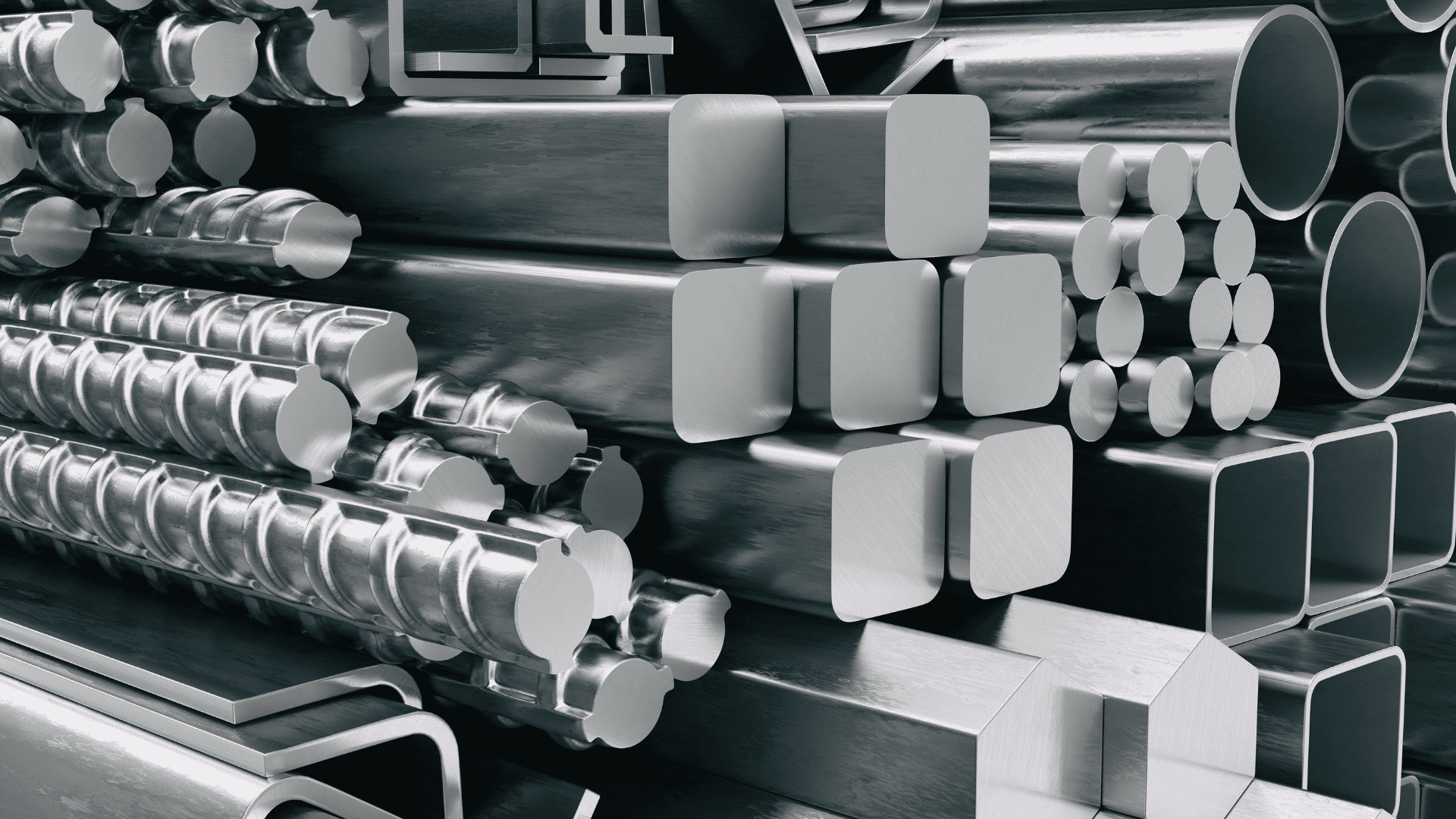

Mild Steel Products and Their Specifications

Mild steel comes in multiple forms, each suited for different fabrication needs. Below is a clear overview of the main products and their key specifications for industrial buyers.

1. MS Rounds

MS Rounds or Cylindrical steel bars are available in various diameters for shafts, rods, and rollers.

-

Diameter: 5–80 mm

-

Length: 6–12 m

-

Grade: IS 2062 E250/E350

-

Note: Ideal for machining and rotational components due to uniform cross-section

2. MS Squares

MS Square or Square bars with consistent dimensions suitable for frames and structural supports.

-

Side: 16–100 mm

-

Length: 6 m standard

-

Grade: IS 2062 E250/E350

-

Note: Provides dimensional stability for mechanical and industrial parts

3. MS Flats

MS Flats or Flat bars are designed for support structures and custom fabrication.

-

Width: 25–200 mm

-

Thickness: 6–25 mm

-

Length: 6 m

-

Grade: IS 2062 E250/E350

-

Note: Easy to cut, bend, and weld for modular structures

4. MS Plates

MS Plates or Flat panels for heavy-duty industrial applications.

-

Thickness: 6–200 mm

-

Size: 1000×2000 mm standard, customizable

-

Grade: IS 2062 E250/E350

-

Note: Provides stable surfaces for tanks, bases, and machinery beds

5. MS Channels

MS Channel or U-shaped profiles are used for rigid frames and modular assemblies.

-

Depth: 50–250 mm

-

Length: 6–12 m

-

Grade: IS 2062 E250/E350

-

Note: Supports load distribution and structural stability

6. MS Angles

MS Angles or L-shaped steel is used for bracing and framework.

-

Type: Equal and unequal angles

-

Thickness: 6–20 mm

-

Length: 6–12 m

-

Grade: IS 2062 E250/E350

-

Note: Lightweight yet strong for industrial support elements

7. MS Pipes

MS Pipes or Hollow profiles for enclosures, ducting, and fluid handling.

-

Shape: Round, square, rectangular

-

Thickness: 2–12 mm

-

Length: 6 m

-

Grade: IS 1239 / IS 3589

-

Note: Provides versatility and load-bearing capacity

Mild steel products offer a versatile range of shapes, sizes, and grades, with specifications designed to meet diverse fabrication requirements while ensuring strength, durability, and ease of processing.

How Mild Steel is Fabricated?

Mild steel is produced through a carefully controlled process that ensures consistent chemical composition, mechanical strength, and versatility for fabrication. Each step in the production chain is designed to optimize the steel for industrial and structural applications.

-

Raw Material Preparation: Iron ore and coal are combined and melted in a furnace. Lime and other fluxes are added to remove impurities, forming a clean molten base.

-

Carbon Adjustment: Controlled oxygen and scrap steel are introduced to reduce carbon content to low levels (typically below 0.25%), producing steel that is both strong and ductile.

-

Refining: Molten steel undergoes treatments such as stirring, degassing, and ladle injection to remove remaining impurities and fine-tune chemical composition.

-

Casting: The refined steel is poured into molds to form slabs, billets, or blooms, which are the starting forms for all subsequent steel products.

-

Forming: The solidified steel is shaped into specific products using hot rolling, cold rolling, or drawing. This step produces rounds, squares, flats, plates, sheets, channels, angles, and pipes.

-

Finishing Treatments: Additional processes like tempering, coating, galvanizing, or polishing are applied to enhance mechanical properties, corrosion resistance, and surface finish, preparing the steel for industrial use.

The fabrication of mild steel involves controlled processes from preparation to finishing, ensuring consistent quality, strength, and versatility for industrial and structural applications.

Advantages of Using Mild Steel in Fabrication

Mild steel offers a combination of strength, flexibility, and cost-efficiency, making it a preferred choice for industrial fabrication. Its properties support a wide range of processes and applications, ensuring reliability and durability.

-

High Ductility: Can be bent, rolled, or shaped without cracking, ideal for custom fabrication.

-

Excellent Weldability: Compatible with MIG, TIG, Arc, and Spot welding for strong, reliable joints.

-

Cost-Effective: Lower production and material costs compared to high-carbon or alloy steels, suitable for bulk industrial use.

-

Consistent Mechanical Properties: Predictable tensile and yield strength ensure reliability in shafts, frames, and structural components.

-

Versatility of Forms: Available as rounds, squares, flats, plates, sheets, pipes, channels, and angles to suit diverse fabrication needs.

-

Surface Finish and Coating Compatibility: Accepts galvanizing, painting, powder coating, and polishing, improving durability and aesthetics.

-

Easy Machining: Can be drilled, milled, turned, and ground with minimal effort, allowing for precise industrial components.

-

Recyclable and Environmentally Friendly: Can be reused or recycled, reducing material waste in fabrication projects.

Mild steel combines strength, flexibility, cost-efficiency, and ease of fabrication, making it a preferred choice for industrial components, structural frameworks, and precision assemblies.

Why Source Mild Steel from SteelonCall?

Selecting a reliable supplier ensures quality, cost-efficiency, and on-time delivery for fabrication projects. SteelonCall offers verified access to a wide range of mild steel products to meet diverse industrial needs.

-

Direct Manufacturer Access: Ensure consistent quality and authentic materials.

-

Verified Supplier Network: Minimize procurement risks with approved suppliers.

-

Competitive Bulk Pricing: Save on large fabrication orders with transparent rates.

-

Safe and On-Time Delivery: Reduce project delays with streamlined logistics.

-

Wide Product Range: Rounds, squares, flats, plates, sheets, pipes, angles, and channels in multiple grades and sizes.

-

Live Pricing & Easy Tracking: Compare rates and manage orders efficiently on the platform.

-

Regional Relevance: Tailored availability for South India markets, including AP, Telangana, and Karnataka.

Get Your Mild Steel Quote Instantly

Conclusion

Mild steel provides unmatched versatility for industrial fabrication, supporting everything from sturdy structural frames to precision machinery components.

Its weldability, ductility, and compatibility with cutting, forming, and finishing processes make it ideal for enclosures, racks, panels, and more.

Sourcing from SteelonCall ensures access to verified suppliers, consistent quality, transparent pricing, and reliable delivery, enabling fabricators to complete projects efficiently while maintaining high standards.

FAQs

1. What are the main applications of mild steel in fabrication?

Mild steel is used for industrial frames, machinery components, enclosures, racks, and panels. Products like rounds, squares, flats, plates, sheets, channels, angles, and pipes can be shaped, welded, and finished to meet specific project needs.

2. How do the mechanical properties of mild steel impact its use?

Its ductility, tensile strength, and yield strength allow mild steel to withstand bending, cutting, welding, and machining, making it ideal for precision components and structural assemblies.

3. Which mild steel products are best for heavy-duty fabrication projects?

MS plates, channels, angles, and pipes are suitable for heavy-duty applications, while rounds, squares, and flats are ideal for shafts, rods, frames, and smaller structural components.

4. How can fabricators ensure quality when sourcing mild steel?

Purchasing from verified suppliers with consistent grading and certifications ensures authentic material, reliable mechanical properties, and transparent pricing.

5. What fabrication processes are commonly used with mild steel?

Common processes include cutting, bending, rolling, welding, machining, and surface finishing like galvanizing, painting, or powder coating, allowing the steel to meet project-specific requirements.