Different Types Of Roofs In Building Construction

A poorly chosen roof system leads to persistent leaks, poor heat resistance, and costly maintenance. These issues compromise a building's safety and occupant comfort, creating long-term operational headaches.

Selecting the correct roof type directly prevents these structural and financial problems. The right roof ensures optimal weather protection, energy efficiency, and architectural appeal for any building.

This guide details the common types of roofs in building construction for your projects. You will learn their specific applications, advantages, and key selection criteria for informed decision-making.

Key Takeaways:

-

Roof design is crucial for managing regional factors like heavy rain and high temperatures.

-

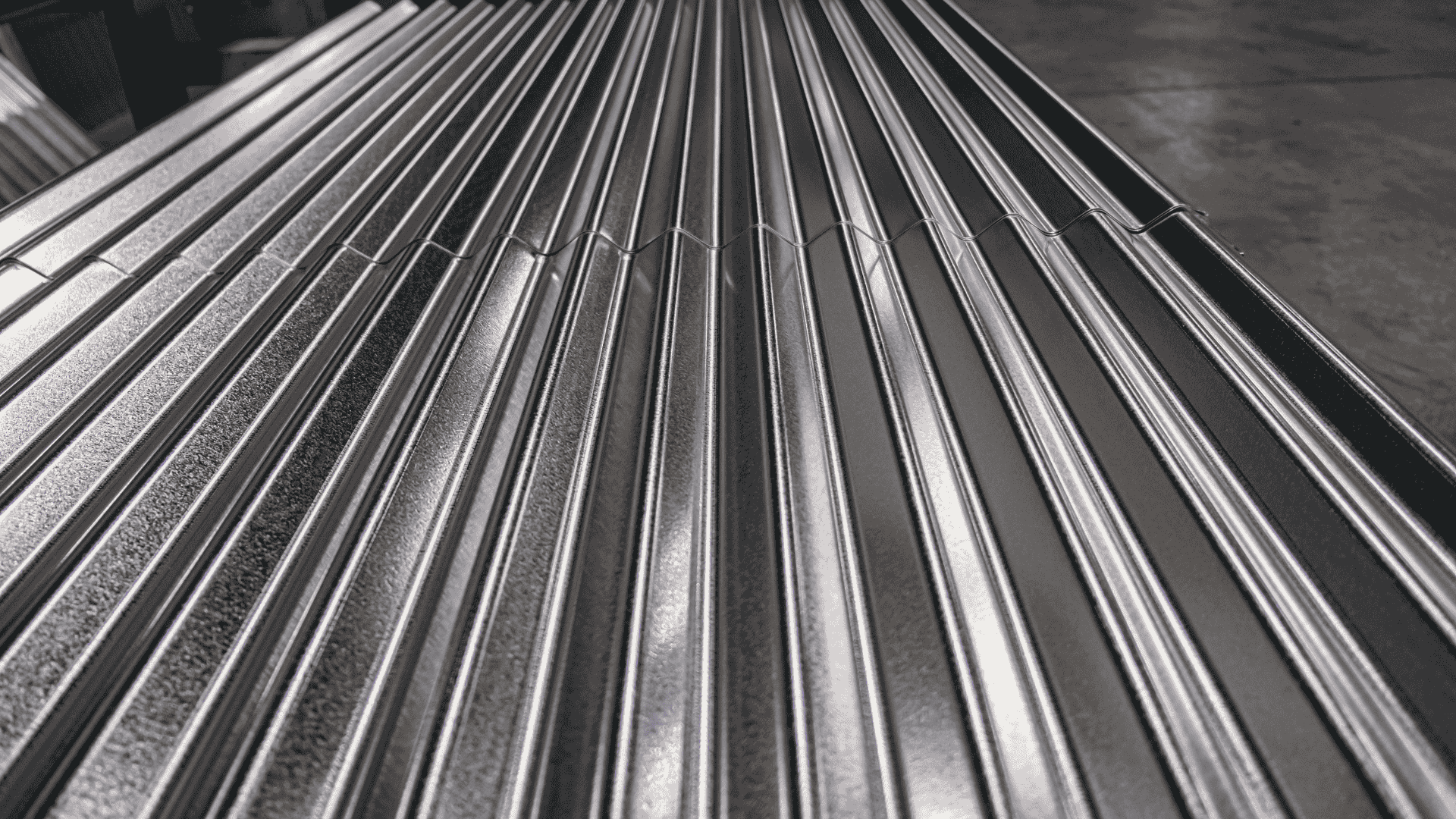

Metal Roofing (GP sheets/roofing sheets) is essential for industrial sheds and quick-build commercial projects.

-

Flat roofs are popular in urban centres like Hyderabad for easy installation of utilities and terraces.

-

Gable and Hip roofs are highly effective for drainage in heavy rainfall areas.

-

Sourcing the correct Fabrication Steel ensures long-term structural stability and weather resistance.

Why is Effective Roofing Important in Building Construction?

Choosing the correct roof profile and supporting steel is critical because the roof defines the structure's long-term protection and performance. A well-designed, properly supported roof prevents water infiltration and manages thermal fluctuations, directly safeguarding the main structure.

This consideration moves beyond aesthetics to become a primary factor in material specification and fabrication planning.

Contractors must prioritise roofing quality to ensure project compliance and client satisfaction across several key areas:

1. Primary Structural Protection and Water Management:

The roof acts as the essential barrier, shielding all interior components and underlying steel from rain, humidity, and direct sunlight. An effective design ensures rapid water runoff, preventing pooling and infiltration that can lead to corrosion and structural damage over time. This protection extends the operational lifespan of the entire building.

2. Direct Impact on Building Energy Efficiency:

Roofing materials and design significantly influence how much heat the building absorbs or retains. Proper roof selection allows for better insulation placement, which reduces the need for constant heating or cooling. This control is vital for managing long-term utility costs, especially for large industrial or commercial structures.

3. Determining the Required Steel Support Framework:

The type of roof structure (e.g., Flat, Gable, Curved) dictates the precise load requirements for the support system below. Fabricators must specify adequate MS angles, beams, and purlins to safely bear the roof's weight and potential loads like rain, snow, or machinery. This structural demand directly influences your bulk steel procurement needs.

4. Compliance and Long-Term Maintenance Reduction:

A roof built with certified, high-quality materials from verified sources meets regulatory standards and minimizes future maintenance requirements. Using authentic steel sections prevents premature failure of the support system, ensuring long-term structural integrity and avoiding costly, disruptive repairs later.

Also read:Choosing Between Galvalume and Galvanized Steel for Your Next Project

Given the structural criticality, choosing the right roof profile is a high-stakes decision driven by project function and regional climate. Here are the types of roofs in building construction that influence your steel component needs.

Different Types of Roofs in Building Construction

Choosing a roof structure is a technical decision guided by budget, climate, and planned use of the building space. Your fabrication plan must accommodate the specific load requirements and material needs of each profile:

1. Gable Roof

This is the most common roof design, featuring two sloping sides that meet at a ridge. Its simple triangular shape is highly effective at shedding water and snow loads quickly. The design allows for excellent ventilation within the attic space, which is beneficial in hot climates.

Best for: Cost-effective industrial sheds and residential projects where simple construction and maximum drainage are prioritised.

2. Hip Roof

The Hip roof has four sloping sides that all meet at a ridge, creating a much more stable and compact structure. This design performs exceptionally well in high-wind zones because the slopes reduce wind uplift pressure. The complexity increases material usage slightly over a simple gable.

Best for: Commercial and residential buildings in coastal or high-wind regions, offering superior stability and a robust profile.

3. Flat Roof

Despite the name, Flat roofs have a very slight pitch to allow for drainage toward scuppers or internal drains. They are economical to build and offer usable exterior space for terraces or HVAC units. Flat roofs require specific, high-quality waterproofing systems to prevent water pooling.

Best for: Urban commercial buildings and projects in Bengaluru or Hyderabad where the rooftop space is valuable for utilities or recreation.

4. Shed Roof (Skillion Roof)

This is the simplest type, featuring a single, flat surface that slopes in only one direction. It is often used for extensions, porches, or modern architectural designs due to its minimalistic look. The steep slope is ideal for quick water runoff and is structurally efficient.

Best for: Modern, functional annexes or buildings requiring quick installation and simple support structures like purlins and rafters.

5. Curved Roof

Curved roofs provide a unique, aerodynamic profile, often used in architectural statement buildings or sports facilities. These roofs require specialised steel fabrication using rolled MS beams or pipes to form the curved supports. They offer excellent resistance to wind uplift and shed rain easily.

Best for: Large commercial centres, auditoriums, and airport hangars where design distinction and large spans are required.

Also read:How to Prevent Corrosion in Steel: Tips for Builders & Fabricators

6. Butterfly Roof

The Butterfly roof features two surfaces sloping inward toward a central valley, often resembling a butterfly's wings. This design is excellent for capturing rainwater centrally and is often used to maximize light on the structure's interior. It requires meticulous steel framing to manage the internal drainage system.

Best for: Modern commercial showrooms and buildings where architectural interest and internal daylighting are design goals.

7. Combination Roof / Hip and Valley Roof

This category refers to the use of two or more different structural types on one building, such as combining a flat roof section with a gable. The structure requires complex steel connections to manage different roof heights and pitches effectively. A Hip and Valley roof is a common combination using standard hip and gable features.

Best for: Large, complex commercial or institutional buildings requiring varied structural profiles for different wings.

8. Blue Roof

A Blue Roof is a functional design specifically engineered to temporarily store rainwater on the roof's surface before slowly releasing it. This type is critical for managing stormwater in dense urban areas like Bengaluru. It demands an extremely high structural load-bearing capacity from the steel framework below.

Best for: Commercial buildings in high-density urban areas needing to comply with strict stormwater management regulations.

9. Metal Roofing, Tile, and Slate Roofing

These terms refer to the material finish, not the structural shape, and are supported by the core structures listed above. Metal Roofing (using GP sheets) is the preferred material for industrial use due to its speed, durability, and use of SteelonCall-supplied fabrication steel. Tile and Slate are heavier finishes primarily used in high-end residential projects.

10. Mansard, Gambrel, and Bonnet Roofs

These are historic or highly decorative profiles known for their distinct aesthetic features and multiple slopes. They are generally seen in residential or heritage structures and are less common in modern bulk commercial or industrial construction. You should confirm the structural specifications with an engineer if integrating these designs.

Also read:Mild Steel Applications in Fabrication: Uses, Advantages & Processes

Knowing which roof type you need is only the first step; securing the specialized steel components presents the next major hurdle. You must ensure the steel supporting these structures is authentic and delivered reliably.

Sourcing Quality and Certainty with SteelonCall

Securing specialized steel for complex roofing is a major logistical hurdle. Unverified local suppliers often provide substandard MS angles or low-quality sheets that compromise stability.

Uncertain delivery and unpredictable bulk pricing squeeze your fabrication margins and complicate project management. SteelonCall offers a solution to address these procurement roadblocks for contractors and fabricators.

We connect you directly to verified manufacturers for all crucial MS angles, beams, and roofing sheets. This marketplace ensures you receive authentic, high-quality material for a stable final structure.

-

Verified Steel Components: Source authenticated MS angles, beams, and GP sheets required for robust roof frameworks.

-

Direct Manufacturer Access: Buy directly from the source to eliminate intermediary costs and ensure fair, transparent bulk pricing.

-

Regional Availability: Consistent supply of fabrication steel sections in primary markets like Andhra Pradesh, Telangana and Karnataka.

-

Quality Compliance: Every product is sourced from vetted suppliers, guaranteeing material that meets required strength specifications.

-

Managed Logistics: Ensure safe and on-time delivery of long-length sections directly to your project site.

You gain supply chain certainty, allowing you to focus on precise fabrication and project execution, not on material risks.

Also read:Latest Iron TMT Bar Prices in India Today

Conclusion

The range of types of roofs in building construction provides solutions for every structural and aesthetic need. Your selection must always align with local climate demands and the necessary support from high-grade fabrication steel. Focus your material procurement on verified MS angles and quality roofing sheets to guarantee long-term performance.

SteelonCall is your dependable digital platform for sourcing the exact construction and fabrication steel required for any roof design. We provide the verified quality and delivery coordination necessary to build with confidence.

Explore our comprehensive range of roofing sheets to secure the perfect supply for your next project. Check out our live prices here.

FAQs

Q. Which roof type is most suitable for heavy rain regions?

Gable roofs and Hip roofs are highly suitable because their steep slopes ensure rapid water runoff. Proper sizing of the gutter system and using durable metal roofing sheets are also critical factors.

Q. What kind of steel is needed to build a metal shed roof?

A metal shed roof requires structural components like MS angles, channels, and purlins for the support framework. The outer layer typically uses lightweight, durable GP sheets or colour-coated roofing sheets.

Q. Are flat roofs used in the South Indian climate?

Yes, flat roofs are common in urban areas like Bengaluru and Hyderabad. They are often chosen for the easy installation of solar panels or utilities. However, they require meticulous waterproofing and a very slight slope for effective drainage.

Q. Why is the quality of MS Angles important for roofing?

MS Angles form the primary framework (trusses and purlins) supporting the weight of the roofing material. Substandard angles can buckle under load, leading to structural failure. You must source verified, high-yield fabrication steel.

Q. What is the benefit of a Shed Roof in construction?

A Shed Roof is simple to design and quick to construct, reducing overall labour time and material waste. Its single-plane slope is aesthetically modern and highly effective for water management in moderate climates.