How Steel is Produced

In the modern world, steel is one of the most widely used metals for the construction process. Steel having many features like modest, reliable, and incredibly versatile that gives durable nature for building structures. With worldwide production running around 1800 million tons for each year, steel is the second mass-produced commodity next to cement. To make steel, iron ore is heated and melted in a furnace where the carbon added and impurities are removed.

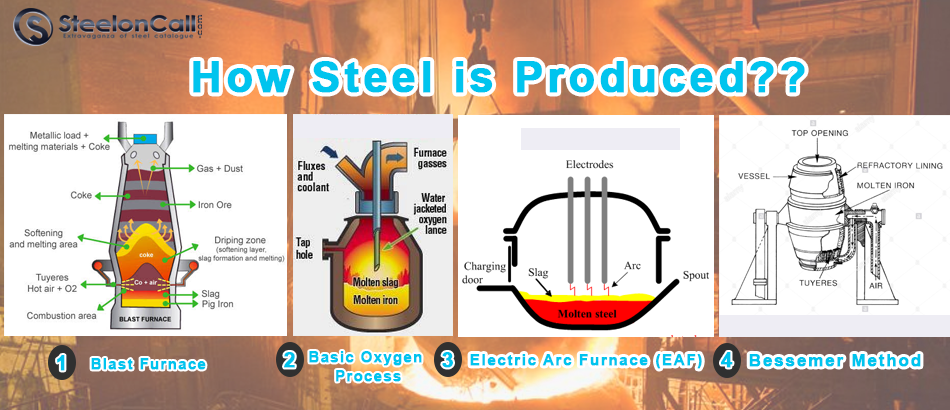

Steeloncall explains the various procedures of steel:

- Blast Furnace

- Basic Oxygen Process

- Electric Arc Furnace (EAF)

- Bessemer Method

Blast Furnace:

Blast furnaces require numerous auxiliary facilities to help their operations. In simple terms, the stove itself is an immense steel shell practically cylindrical in shape and hollow fit as a fiddle and fixed with heat-safe brick. Once the process started, the furnace regularly works until the refractory coating needs reestablishment or until the demand for iron drops to the point where the stove is closed down. The span of furnace activities all the way is alluded to as a battle and may last several years.

Basic Oxygen Process:

It's employed as a coolant to control high temperatures produced by exothermic responses between the blast furnace iron and oxygen. About 75 will be liquid iron, and 25 will be from scrap. Oxygen is also blasted through a shaft that's lowered into molten essence. The oxygen combines with impure rudiments, phosphorus, carbon, manganese, and silicon to produce an exothermic response. Lime is also added to the furnace to help separate different contaminations and transfigure them into sediment. This stage keeps going around 20 twinkles; at that point, a sample is taken for the structure of the essence. Presently we need to force the steel to leave a valve gap into a vessel to insulate the sediment from the iron. Changes in the emulsion conflation are needed; at that point, a secondary steelmaking process starts.

Electric Arc Furnace (EAF):

The utilization of EAFs is to primarily produce special quality steels, which are alloyed with different metals. EAFs can also be utilized to produce non-alloyed steels and ordinary steels. In contrast to the heaters, EAF's don't use hot metal. They use steel scrap from reused items. The scrap steel is tipped into the electric Arc Furnacefrom an overhead crane. When the furnace is full, the lid is closed, covering the highest point of the stove. The cap contains electrodes that are lowered down into the furnace. The wires get charged with a powerful electric flow, which creates heat along with the melting of the scrap. As the trash melts, different metals known as Ferro-compounds are added to the steel to give it the ideal synthetic structure. Oxygen is blown into the furnace to clean the iron. Lime and fluorspar are added to combine with the contaminations and structure slag. The liquid residue drifts on the highest point of the molten steel are poured off by tilting the furnace. A range of extraordinary quality steels is made in EAF's by combining different metals to shape steel alloys. The most broadly utilized of these is stainless steel, which has nickel and chromium added to give it corrosion-resistant properties. Other unique irons made in EAFs include steels used in designing, aerospace, and armor plating.

Bessemer Method- Traditional Method of SteelMaking:

In Bessemer's strategy, pig iron is oxidized in a Bessemer converter. That is used to oxidize the iron. As the metal is oxidized, it stays at the correct temperature to keep the steel liquid. During this procedure, impurities in the iron combine with the oxygen. It makes a variety of oxides, through which we can remove contaminants in this way. Carbon monoxide releases in the process, but it merely burns off. While a significant part of the iron that is utilized in steel making comes directly from iron ore, it is also possible to fabricate steel from reused materials. Reused steel can 7be transformed into high-quality steel products, and it is a common source of iron for steel making. There are numerous potential sources of reused steel, for example, utilized vehicles, instruments, parts, and even gadgets. All the mentioned steel produced process will help to know in which way the steel is going to be delivered. Steeloncall briefly explains all types of steel process that must be understood by everyone.