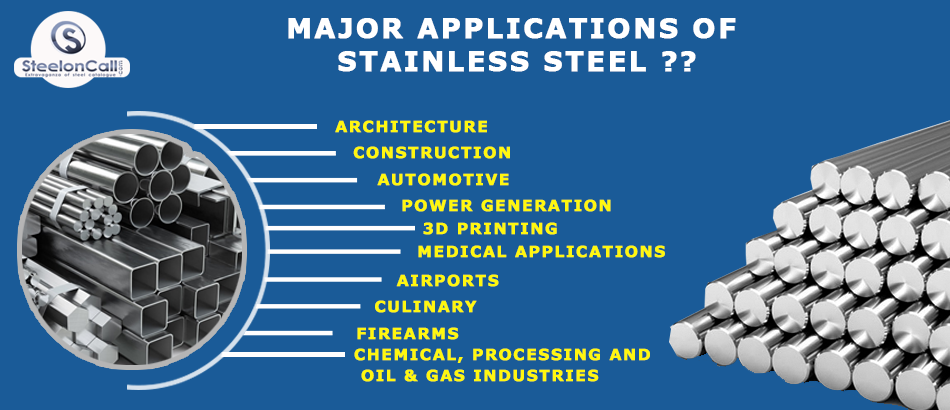

Major Applications Of Stainless Steel

Stainless steel stand firm in the rain as well as gives minimum maintenance pain. Its all-powerful nature is expected to the incredible physical and chemical properties, and it shows under a broad scope of temperature and weight. During its residency, stainless steel has made its presence all over, from a little pin to an airplane. There is no uncertainty that stainless steel primary material for a full cluster of industrial applications. It is known for its exceptional quality, corrosion resistance, life span, malleability, and acid resistance. This is the reason stainless steel is the primary decision for industries with regards to utilizing steel in an application.

Some of the uses of stainless steel; is briefly explained by Steeloncall below.

Architecture:

Stainless steel is utilized for structures for both down to earth and stylish reasons. Because of the durability of the material, many of these structures still hold their unique appearance. Stainless steel is utilized today in building construction because of its durability and because it is a weldable structure metal that can be made into stylishly satisfying shapes.

Construction:

Due to its quality, adaptability, and protection from corrosion, stainless steel is currently used in present-day construction. It is utilized in the outside cladding for enormous high effect structures and can be found in the insides, too, like handrails, ledges, backsplashes, and more.

Automotive:

Vehicles are utilizing stainless steel, fundamentally for exhaust frameworks (grade 409) and exhaust systems, yet in addition to ancillary purposes. With more significant consideration being made to accomplishing low-term maintenance costs, more substantial concern with life cycle costs, and less environmental impact, the market for stainless steel continues to improve.

Power Generation:

Stainless steels and other corrosion-resistant composites are broadly utilized in the power age industry to battle corrosion, especially at raised temperatures. Correctly nickel alloys are used for high-temperature quality and oxidation resistance in fossil-fuelled power plants. Nickel alloys and various stainless steels are widely utilized in flue gas desulfurization units. The nuclear power industry also uses enormous amounts of stainless, frequently indicated, low cobalt content, for both power age and radiation regulation.

3D Printing:

Some 3D printing suppliers have created exclusive stainless steel sintering mixes for fast prototyping. One of the more well known stainless steel grades utilized in 3D printing is 316L stainless steel. Because of the high-temperature gradient and rapid rate of solidification, stainless steel products manufactured using 3D printing will, in general, have a progressively refined microstructure, thus bring about better mechanical properties.

Medical Applications:

Low carbon content and high corrosion resistance are key factors that make Stainless Steel 304 reasonable for medical applications far beyond different Stainless steel grades. The consolation that medicinal gadgets won't artificially respond with substantial tissue, cleaning items used to sanitize, and the hard, repetitive wear that numerous medical devices are exposed to, implies that Stainless 304 is the ideal material for medical types of equipment, medical surgeries, medical procedures and paramedic applications, etc.

Airports:

Stainless steel is a modern trend for roofing material for air terminals because of its low glare reflectance to shield pilots from being blinded, additionally for its properties that allow thermal reflectance to keep the surface of the roof close to ambient temperature.

Culinary:

Stainless steel is regularly favored for kitchen sinks due to its roughness, solidness, heat resistance, and ease of cleaning. In better models, acoustic noise is controlled by applying strong undercoating to hose vibrations. The material is likewise utilized for cladding of surfaces, for example, appliances and backsplashes. Cookware and bakeware may be clad in stainless steel, to improve their cleanability and durability, and to allow their utilization in enlistment cooking (this requires a magnetic grade of stainless steel, such as 432). Because stainless steel is a poor conductor of heat, it is regularly utilized as a meager surface cladding over a center of copper or aluminum, which leads to more prompt anger.

Firearms:

Some firearms incorporate stainless steel parts as an option to blued or parkerized steel. Some handgun models, such as the Smith & Wesson Model 60 and the Colt M1911 pistol, can be made altogether from stainless steel. This gives a high-shine finish comparable in appearance to nickel plating. In contrast to plating, the finish isn't liable to chipping, stripping, wear-off from rubbing (as repeatedly removed from a holster), or rust when scratched.

Chemical, processing, and Oil & Gas Industries: Probably the most demanding industries that utilization of stainless steel are the chemical, processing, and oil & gas businesses that have made an enormous market for stainless tanks, pumps, funnels, and valves too. One of the first significant examples of overcoming adversity for 304 stainless steel was the storage of dilute nitric acid as it could be utilized in thinner sections and was more robust than different materials. Excellent grades of stainless have been created to have more prominent corrosion resistance at a broad scope of various temperatures. These are utilized in desalination plants, sewage plants, offshore oil rigs, harbor supports, and ship propellers.

Stainless Steel material continues to discover its way into new applications on a close to daily bases. Mentioned number of applications where stainless steel has proven itself through many years of reliable help and are utilized in numerous places.