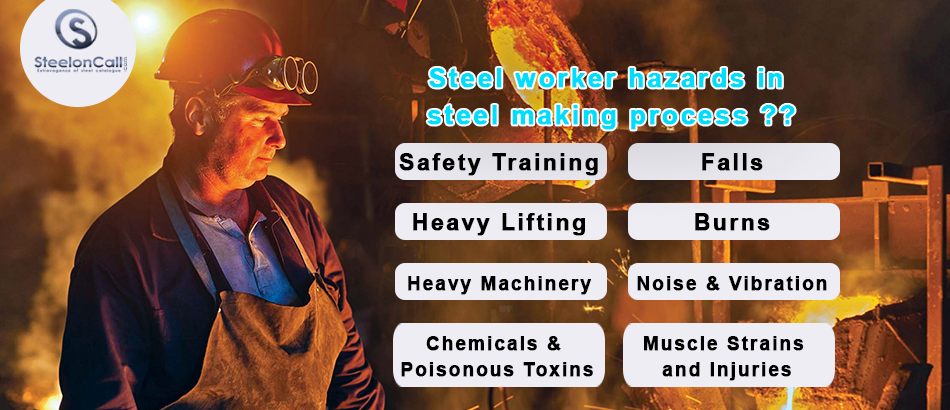

Steel worker hazards in steel making process

The steel business is considered one of the most elevated hazard environments for workers and causes various health problems. Still, finally, they are proving the quality steel materials that are ideally used for construction projects. The dangers culminate from the exposure to critical/dangerous areas while in the profession. To more readily understand the risks should be initially analyzed, the environment in which steel workers execute their duties. It is better to review some of the standard and most likely dangers affecting steelworkers.

Now Steeloncall explained some of the safety measures that must be taken while they are working on the manufacturing of quality steel materials.

Just follow the below guidance to save their life from steel operating hazards.

Safety Training:

As a matter of first importance, the steel laborers needed to undergo safety training. Every worker should be provided with suitable training. Training on different types of machinery on which they work is required. Workers know what PPE(Personal Protective Equipment) they are required to wear, and the dangers of working each machine are understood to keep away from accidents. Loose clothing, long hair, and jewelry represent a high chance risk around tools and hardware machinery as they can get trapped in quick moving parts, potentially setting off a severe mechanical industry accident. Skin burns caused by heated equipment or synthetics utilized during the steel fabricating process are different examples of dangers to workers in the steel business they face on a day to day work.

Falls:

Steelwork frequently involves working at significant heights, uneven ground, and obstructed walkways. It's nothing unexpected that slips, trips, and falls are the primary source of injuries among steelworkers around the world.

Heavy Lifting:

Occupations in the steel business are physically requesting. They require continued lifting, bending, and different types of effort. At the point, when laborers perform strenuous tasks throughout every day, their bodies will be susceptible to become weak. The injuries that are mainly on back, neck, knee, and shoulder are prominent among steel laborers.

Noise & Vibration:

Over decades, noise & vibration aspects presented as dangers for the laborers. Working substantial hardware in itself requires some ability and training. The untrained staff makes a hazard to the laborers. The machinery also emits some vibration that may cause nerve harm and wear down tendons and ligaments. Hearing loss is basic among steel workers because of the constant exposure to noise at the factories and building sites, particularly when the correct ear protection is not worn.

Burns:

Steelworkers weld all the time, which can lead to burns. Not only can welding hardware equipment scorch hands and limbs, but also it sparks can fly into eyes, causing severe damage. When welding, steel workers must wear protective glasses, attire, and welding gloves to prevent these sorts of risks. Moreover, fumes and heat from welding activities, mainly when working close to burnable materials, can prompt fire, bringing about immense risks or death.

Chemicals

& Poisonous Toxins: Working around harmful chemicals and harmful toxins are very risky long-term. They could prompt different kinds of cancers and harm to the endocrine system. So ensure proper pollution controls made not to release into the environment without treatment them for harmful pollutants.

Heavy Machinery:

Powerful machinery assumes an essential job in the steel business. It additionally adds to various risks and fatalities. Despite ample warnings, thorough training, and inherent shields, accidents still occur. Individuals cut corners, hardware breaks down, and safety mechanisms fail.

Muscle Strains and Injuries:

Steelworkers are frequently required to do the hard work while lifting heavy loading and unloading the building steel materials and carrying the steel at construction sites. Other machinery, like cranes and forklifts, can be utilized; however, there is some part of the lifting that the laborers carry out. Heavy lifts lead to back arm and shoulder muscle strains that could lead to body pains in the same area.

If you or anyone you know in a steelworker, consider these hazards carefully. Take full-precaution to avoid the danger of damage at work. Even though it is difficult to wipe out the risks faced by steel workers, it is possible to reduce them by prioritizing safety.