Things to consider while choosing a stainless Steel

Stainless steels are generally outstanding for their corrosion resistance, which increments with adding chromium content. Additions of molybdenum expand corrosion resistance in lessing acids and against setting attack in chloride results. Hence, there are grades of stainless steel with shifting chromium and molybdenum substance to suit the condition that the amalgamation must persist. Low conservation, Resistance to erosion and staining, familiar luster make stainless steel a perfect material for some operations where both the quality of steel and erosion resistance are needed.

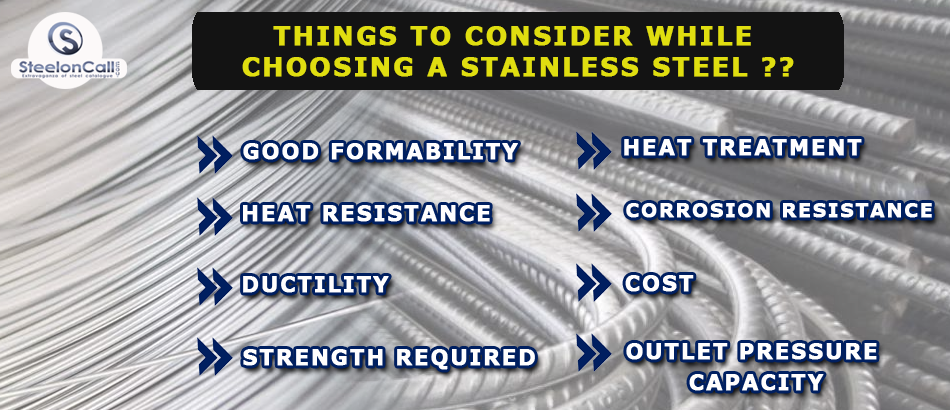

Some of the major effects that demanded to be considered while opting the stainless steel, they include

- Good Formability

- Heat Resistance

- Rigidity

- Strength Needed

- Heat Treatment

- Corrosion Resistance

- Cost

- Outlet Pressure Capacity

Good Formability:

Stainless Steel requires good formability, for maintaining a martensitic gathering of stainless steels. Essay an austenitic grade, for illustration, 304 or a ferritic grade similar as 430. Martensitic stainless steels like 410 will, in general, be weak and aren't instantly formable. Austenitic stainless steels are generally the stylish decision with respects to formable toughened brands.

Heat Resistance:

The temperature of the terrain is also a significant factor. High temperatures like those plant in heater conditions (900 – 1175C) quicken erosion rates and apply fresh pressures on stainless steel products. They bear a further top grade of stainless steel, substantially designed for heat resistance, similar as 253MA or 321.

Rigidity:

Rigidity is one of the most significant intriguing points while getting stainlesssteel.However, one ought to consider the steel grade with high inflexibility like the stainless steel, which can be shaped by exercising the dangerous procedures like deep delineation, If one needs the stainless steel to produce effects like cables where extending the steel is needed.

Strength Needed:

Steel quality is a significant consideration before choosing your grade, yet this is a confused bone. The necessity will depend on the steel's purpose and the kind of condition it's being introduced in. High strength stainless steels are accessible in duplex, austenitic, and martensitic groups; still, the most dependable steel may not generally be reasonable. For illustration, high- quality austenitic brands delivered by work solidifying aren't applicable where welding is done, as it mellows the steel.

Heat Treatment:

Stainless steel requires heat treatment; at that point, you should realize that different steel grades respond else to heat treatment. So if one thinks heat treatment is necessary, it may consider rush and martensitic steel like 440C or the 17-4PH.

Corrosion Resistance:

Stainless steel is also known for its erosion resistance in numerous surroundings in which carbon and low amalgamation tool brands would erode. The erosion resistance is a consequence of an extremely slim (around 5 nanometers) oxide subcaste on the steel's face. This oxide subcaste is indicated to as an inactive subcaste since it renders the face electrochemically idle within sight of sharp surroundings.

Cost:

All of the considerations that are given over will not make any difference if the expenditure of the material is not under one's fiscallimit.However, at that point that stainless steel has a advanced possibility of performing for the long term, which will ultimately be a value for your plutocrat, If one finds steel that matches all of these factors. Other than the original cost, there might be some support costs that one should consider before buying the stainless steel for construction, or different systems use. So one can estimate how much a specific steel material will bring you for your anticipated timeframe.

Outlet Pressure Capacity:

Outlet pressure capacity is outfit to the regulator that's associated that requires gas at a specific weight. Therefore, one should choose a stainless steel controller compatible with any given pressure demand.

Examples Of Stainless Steel

- Ferritic Stainless Steels

- Grade 409 Automotive exhaust systems and heat exchanger

- Order 416 Axles, shafts, and fasteners

- Order 430 Food assiduity and appliances

- Degree 439 Automotive exhaust systems factors

- Martensitic Stainless Steels

- Grade 410 General purpose martensitic stainless steel

- Grade 440C Bearings, shanks, and other wear-resistant operations

Duplex stainless steels

- 2205 Heat exchangers and pressure vessels

- 2507 Pressure vessels and desalination shops

- Rush Hardened Stainless Steels

- 17-4 PH Aerospace, nuclear, and chemical applications

- 15-5 PH Faucets, fittings, and fasteners

Austenitic Stainless Steels

- Grade 303 Fasteners, fittings, gears

- Grade 304 General purpose austenitic stainless steel

- Grade 304L Grade 304 applications that bear welding

- Category 309 Applications involving elevated temperatures

- Category 316 Chemical applications

- Grade 316L Grade 316 operations that bear welding

Stainless steel is best known for its erosion resistance, yet there's much further to the metal than a single trait. Its fashionability also derives from numerous other advantages, including a high strength-to- weight rate, excellent formability, and low support conditions. Another significant advantage is its capacity to be reused and reclaimed, making it complete as a product material.