What Are Different Types of Stainless Steel Grades

Stainless steel grades are generally outstanding for their corrosion resistance, which increases with chromium content. Additions of molybdenum build corrosion resistance in diminishing acids and against pitting assault in chloride arrangements. Along these, there are various grades of stainless steel with varying chromium and molybdenum substance to suit the condition the alloy must persevere. Now, steeloncall is here to provide the information regarding types of stainless steel grades that are used in our day to daily life.

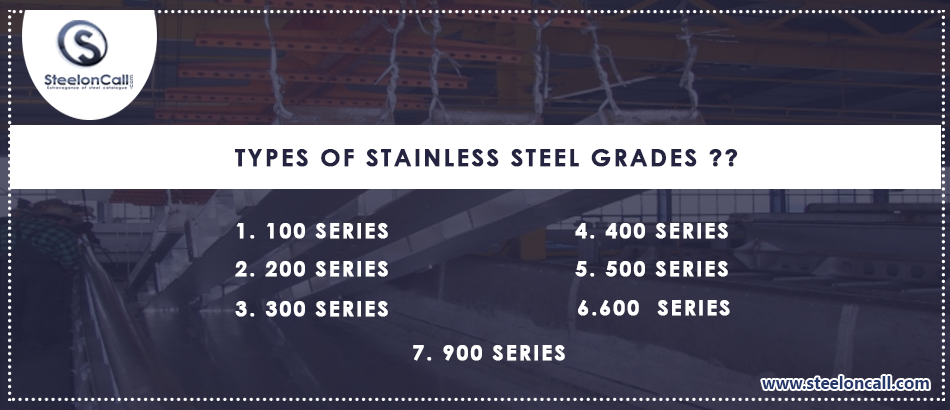

STAINLESS STEEL GRADES TYPES:

- 100 Series

- 200 Series-Austenitic chromium-nickel-manganese alloys

- 300 Series-Austenitic chromium-nickel alloys

- 400 Series-Ferritic and martensitic chromium alloys

- 500 Series-Heat-resisting chromium alloys

- 600 Series-Initially made for exclusive combinations (which are no longer given SAE grade numbers)

- 900 series-Austenitic chromium-molybdenum alloys

100 Series:

The different arrangement of stainless steel grades all have unique qualities. A few conditions that are exceptional to the 100 series incorporate with the composition of austenitic chromium-nickel-manganese alloys that are accessible in two sorts: type 101 can be solidified through cold working and model 102 is a more general kind of stainless steel.

200 Series(Austenitic chromium-nickel-manganese alloys):

The 200 series is a class of austenitic and exceptionally high corrosion-resistant stainless steel portrayed by having low nickel content. They're additionally alluded to as chrome-manganese (Crum) stainless steel. Series 200 stainless sheets of steel have phenomenal effect resistance and toughness. However, even in low and cryogenic temperatures. They're commonly harder and more durable than 300 series sheets of steel, fundamentally because of their higher nitrogen content, which goes about as a strengthening.

300 Series(Austenitic chromium-nickel alloys):

- Type 321: Similar to 304 yet lower danger of weld decay because of the addition of titanium.

- Nature 316: Otherwise called marine grade stainless steel due to its increased resistance to chloride corrosion compared to model 304. The second most regular grade after 304 for food(nourishment) and surgical stainless steel uses. Alloy expansion of molybdenum prevents specific types of corrosion. SS316 is regularly utilized for building atomic reprocessing plants.

- Class 309: Better temperature resistance than 304

- Level 304: The most widely recognized grade is classic 18/8 stainless steel. Also referred to as A2 as per ISO 3506 standards.

- Type 303: Easier machining form of 304 utilizing expansion of phosphorus and sulfur. Likewise alluded to as A1 as per International Organization for Standardization ISO 3506

- Type 302: Same corrosion resistance as 304, with marginally higher quality because of extra carbon.

- Type 301: Highly ductile for framed items. Additionally solidifies quickly during mechanical working. This series has excellent weldability, fatigue strength, and better wear resistance.

400 Series(Ferritic and martensitic chromium alloys):

- Type 440: Further expands chromium and carbon to improve sturdiness and corrosion resistance. Typical applications incorporate instruments.

- Model 431: Contains expanded chromium for more prominent corrosion resistance and exceptional mechanical properties. Commonplace applications incorporate high-quality parts, for example, valves and pumps.

- Model 420: Contains developed carbon to improve mechanical properties. Typical applications include surgical instruments.

- Model 416: Grade 416 contains added phosphorus and sulfur for improved machinability. Typical applications incorporate screw machine parts.

- Model 414: Grade 414 has nickel added 2% for enhanced corrosion resistance.

- Model 410: Basic martensitic grade, containing the most reduced alloy content of the three structural stainless sheets of steel like 304, 430 & 410. Low cost, broadly useful heat treatable hardened steel. Utilized widely where erosion isn't extreme air, water, a few synthetic compounds, and nourishment acids.

- Type 409: Grade 409 is referred to as titanium-stabilized ferritic stainless steel. Although regarded as a general-purpose chromium stainless steel, the practically selective application for Grade 409 is automotive fumes frameworks. Its uses are those where appearance is an optional thought to mechanical properties and corrosion resistance, especially at high temperatures and where some weldability is required.

600 Series:

600 Series initially made for exclusive combinations which are never again given SAE grade numbers

- Type 630: Grade 630 martensitic precipitation hardening stainless steel has a mix of high hardness and quality after appropriate heat treatment. It additionally has comparable corrosion and heat resistance to Grade 304. The terms Type 17-4PH & 630 refer to the same grade.

900 Series(Austenitic chromium-molybdenum alloys):

Type 900 is like 316 yet with higher chromium and molybdenum content for more corrosion resistance.

Protection from erosion and recoloring, low support, and recognizable luster make stainless steel a perfect material for some applications where both the quality of steel and corrosion resistance is required.