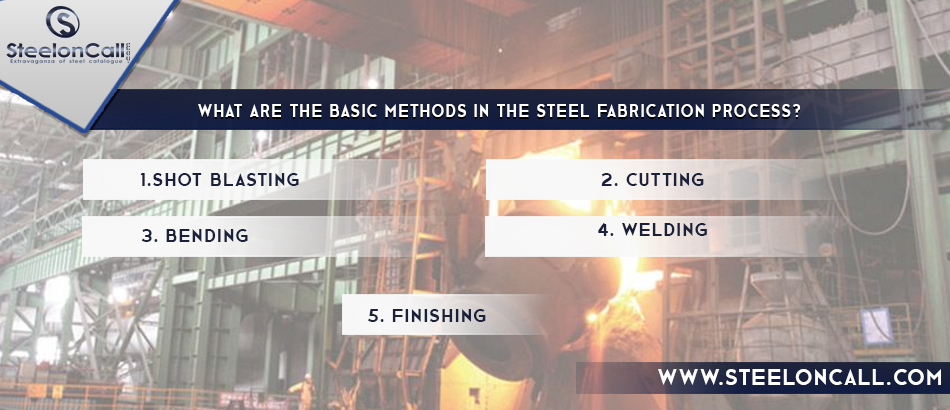

What are the basic methods in the steel fabrication process?

The significance of steel has been getting immensely high. Steel has a solid and tough type of material that makes it longer enduring to exist in your life. Iron and carbon are the two principle fixings that are a piece of steel fabricating production. It would prefer to be sorted out to be the piece of the limited quantity of the oxygen, sulphur, phosphorus and silicon. Steel must contain under 2% carbon and 1% manganese. The fundamental strategies engaged with the steel metal procedure and there are numerous sorts of steel fabrication techniques are cutting, drilling, straightening, machining, punching, bending and folding, fastening, finishing, fitting and reaming, etc. Steel fabrication is a complex process. A considerable lot of us guess that fabricating steel is simple once one has the proper equipment. There are various types of strategies in which the steel fabrication process is considered. Below are some of the procedures of steel fabrication techniques that discussing each one of these methods:

1.SHOT BLASTING

Shot blasting is usually utilized for the steel, cleaning of iron, non-cast parts, forgings and so on. Surface treatment with high-speed steel grating is known as shot blasting. Shot blasting is a method for obtaining excellent cleaning and surface preparation for secondary finishing processes. Shot blasting machine is a mechanical technique for moving abrasive utilizing a centrifugal wheel to remove surface and different polluting influences from the outside of steel applications. For the most part, blasting prior to finishing serves three essential needs: It cleans and descales surfaces, adds surface to improve paint attachment and appropriately decreases upkeep costs by expanding covering life.

2. CUTTING

Maybe the most ordinarily utilized steel fabrication processes involve cutting, where steel metals are part into equal parts, thirds or littler segments. In plenty of utilizations, the steel being cut is newly made and presently can't seem to be molded into anything specifically. Pre-formed metals, such as bars and estimated boards, are submitted for cutting in a variety of purposes. Cuts are made with a variety of machines, ranging from lasers and plasma torches to increasingly complex and inventive technology. Scope of procedures and mechanical assembly are utilized to cut steel areas, for example, circular saws, flame cutting or plasma cutting techniques. This makes areas simpler to work with pushing ahead.

3. BENDING:

Flexibility is a measure of the degree to which a material can strain or lengthen between the beginning of yield and inevitable crack under tensile loading. The designer depends on ductility for various aspects of design including redistribution of stress at a definitive farthest point state, bolt group design, decreased danger of weariness split engendering and in the fabrication processes of welding, bending and straightening. The different gauges for the grades of steel have a minimum value for ductility so the structure suspicions are valid and if these are determined accurately the creator can be guaranteed their satisfactory presentation.

4. WELDING:

Welding is a semi-automatic process that is done accurately and offers a solid joining of two pieces of steel materials. This procedure utilizes an argon rich protecting gas and a strong wire cathode. The welding procedure is mainstream since it permits the welder to use a beat current inventory, which can make it simpler to weld that intense to-arrive at spots on complex steel projects. Different gases blends, incorporating those with helium, oxygen and carbon dioxide, are regularly used to balance out the circular segment and improve the nature of the weld. Welding is a procedure of consistently joining at least two bits of metal together utilizing heat and pressure. At the point when the heat is applied to metal, it turns out to be delicate, empowering parts to be joined by applying satisfactory weight. The idea of welding has been in existence since the medieval times when metal pieces were first heated on a flame at very high temperatures before being pounded together to go along with them. This includes utilizing high heat to melt the parent material along with whatever is being appended to it, so that as the weld pool solidifies the two materials are combined.

5. FINISHING:

A procedure in which a finished steel metal undertaking's surface is adjusted to accomplish a specific property, which incorporates improved appearance, grip or weldability, solderability, hardness, electrical conductivity, erosion, discolor compound or wear opposition, surface rubbing control and imperfection expulsion. When a steel area is finished it might be done in a specific covering. This is required for a scope of tasteful and viable reasons, for example, to secure the steel against erosion and fire or to give a custom look when mentioned by the engineer.

At last, we would state that the procedure of steel fabrication is the same. However, you will toward the end be seeing the steel item as various. One might don't know the way that there are around 3,000 sorts of different steels. Every single one of them has its own property as some of them are physical, substance, and natural.