What Are The Different Ways Of Tying Binding Wire?

One of the significant utilization of binding wires is to keep the reinforcement provided in the proper place, because without the binding wire support will be allowed to move specific segments. Binding Wire can prompt the reduction in quality and malleability of the structure and increase the chances of failure. AIn the applicable business, we are showing a predominant quality scope of MS binding wire that is used in the construction field. Experts utilize cutting edge technology and high-grade mild steel while producing this binding wire. Aside from this, our offered binding wire is tried against various parameters under the direction of our quality analysts that are mainly used in the construction field.

Binding wire with heat treatment will have high quality and become gentler. Spread the wire with zinc, its protection from consumption will be solid. The galvanized binding wire has a matte or shiny finish, and it is anything but difficult to contradict the negative impacts of nature. PVC covered binding wire has protection from consumption. It helps in making a reinforcement cage and holding it set up. A structural section has regularly longitudinal just as transverse support. A typical practice is to develop this cage on the ground, afterward set up it. Presently these bars won't remain associated with one another in a careful spot as when we move the enclosure, it will make some bending. So as to ensure that it remains in the specific needed position. Everyone utilize this binding wire and tie at the crossing point of various reinforcement structures.

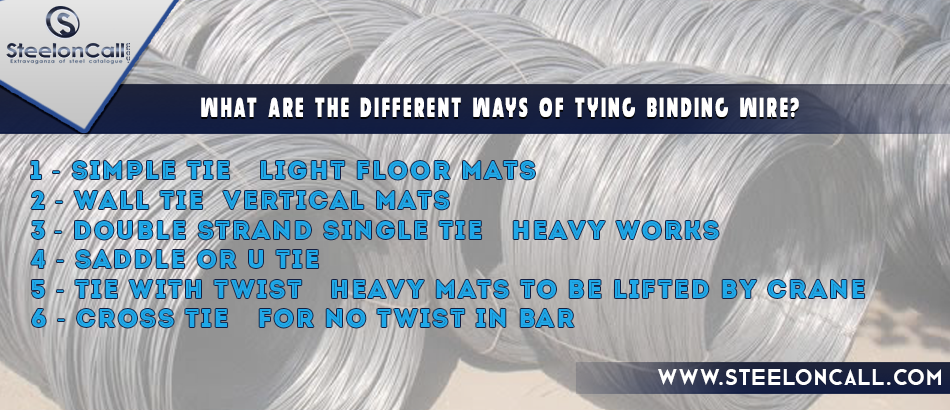

DIFFERENT WAYS OF TYING BINDING WIRE:

There are different kinds of ties utilized when verifying strengthening bars. A great part of the tying is done on a level, even structure work, for example, floor chunks, and numerous spinal pains can be spared if one figures out how to twist and tie firm legged instead of squatting. Several of the most widely recognized kinds of ties are described below

- Simple Tie - Light floor mats

- Wall Tie -Vertical mats

- Double-Strand Single Tie - Heavy works

- Saddle or U Tie

- Tie with Twist - Heavy mats to be lifted by crane

- Cross Tie - For no twist in bars

SIMPLE TIE- LIGHT FLOOR MATS

A snap or single tie is typically utilized in level flatwork to secure the reinforcing bars in position against displacement due to work done by other trades and by concrete placing. This is a basic tie; it is wrapped once around the two intersection bars in an inclining way with the two-wire finishes on top. The wires are then twisted together with a couple of forceps until they are tight against the bars. The wire is cut with pliers and the ends flattened, to keep them from catching dress and from jutting through the solid surfaces. This kind of tie is additionally utilized when tying bars in caissons, now and again utilizing No. The snap or single type binding wire is made stronger by and around the primary bar where they are twisted.

WALL TIE -VERTICAL MATS

Steel Wire is additionally utilized in the structure and development industry because of its high corrosion resistance and strength. Wall ties are created from SS wires for controlling brickwork, blockwork and stonework. Snap tie with a round turn or wall tie. As the name indicates this tie is utilized for tying the even bars in long shear dividers, compound dividers where the basic tie isn't fit for holding the level ones.

DOUBLE STRAND SINGLE TIE - HEAVY WORKS

Double strand single tie is like a straightforward tie however as opposed to utilizing a single wire, we utilize double binding wire and tie in a similar way.

SADDLE OR U TIE

This sort of tie is complex than different ties however is great in certain areas, for example, for tying establishment fortifications/shear dividers. The profitability is reduced as this tie is additional tedious.

TIE WITH TWIST - HEAVY MATS TO BE LIFTED BY CRANE

These bonds are like U tie yet one and a half overabundance turns are wrapped which gives additional solidness to the reinforcements utilized fundamentally for substantial rafts or in the case where precast reinforcements are finished.

CROSS TIE - FOR NO TWIST IN BARS OR FIGURE-EIGHT TIE

This tie can give the most extreme protection from twisting of the bars and allowing immense burden on the reinforcements. With the utilization of such ties, irregular ties can be given.

In the present situation, this sort of binding wire tying is generally utilized in the development business. Encasing a solitary wire around the transverse bars of steel and afterward winding the two parts of the bargains a regular snare which is made of mellow steel until they are sufficiently tight.