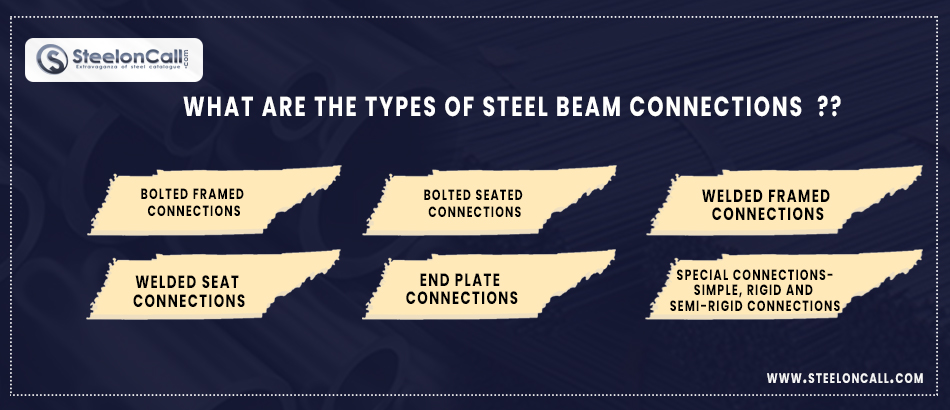

What are the types of Steel Beam Connections?

Steel beam connections can likewise be required for slanted joints, pillars unusual to sections and association with segment networks. These are classed as extraordinary connections and are treated separately. Steel beam connections come up with various sorts. Presently steeloncall have given the explanation of the considerable number of sorts of steel beam connections in the below section.

- Bolted framed connections

- Bolted seated connections

- Welded framed connections

- Welded seat connections

- End plate connections

- Special connections-simple, rigid and semi-rigid connections

1. BOLTED FRAMED CONNECTIONS:

Regularly, the connection is planned dependent on the heaps toward the end of the beam. It is required to take quality, type and size of latches and quality of base materials into thought while the connection is designed. The minimum length of connection angle ought to be at any rate half of the bar clear web profundity. This measure is indicated to guarantee adequate firmness and soundness. There are different standard sizes of bolted framed connections along with their ability given by codes. The reason for such institutionalized associations is to speed up the plan.

2. BOLTED SEATED CONNECTIONS:

Bolted seated connectors come in two varieties:

- Stiffened connections and

- Unstiffened connections

If the reaction force toward the finish of the bar is enormous, at that point it is prescribed to utilize stiffened connection type as it has the vital solidarity to oppose these powers. Though, in the event of unstiffened connection type, there is a breaking point to oppose the powers. Seat connections are practical to manufacture and it offers quick help during erection. Aside from this, they don't require quite a bit of main steel beam detailing as well. These connections are environment-friendly as the structure having this connection can be disassembled and utilized in different activities.

3.WELDED FRAMED CONNECTIONS

The aim with welded construction is to guarantee that the principle pillar-to-section connections are made in a factory situation and can be full quality unbending joints. To accomplish this, while as yet keeping the piece estimates little enough for transportation, short stubs of the mild steel bar segment are welded to the sections. The connection of the stub to the rest of the beam is regularly made with a bolted cover plate splice. Note that the bolted splices should utilize preloaded jolt gatherings.

4.WELDED SEAT CONNECTIONS

It is like a fastener bolt seat connection however welding is utilized for fastening rather than bolts. The heaps on the steel beam bar influence the weld design unusually and produce pressure. Along these lines, as welded framed connections, such burdens should be thought of. Some of the types of welded welded seat connections include unstiffened seat and stiffened seat. The previous is utilized on account of little applied burdens though the last is appropriate for instance of huge burdens.

5. END PLATE CONNECTIONS

An adaptable end plate connection comprises a plate secured to the two sides of the web in metal pillar structures by filet welds. The connection ought to transmit vertical shear and permit bar end pivots to happen without the advancement of huge minutes. They give minute safe connections between beams and columns at the side of edges or a minute opposing resisting connection to elongate beams. Ordinary adaptable end plate connections might be incomplete profundity or full-profundity and are welded to the upheld metal bar structures. The pillar at that point jolts to the supporting shaft or segment nearby. This sort of connection is generally low-estimated however has the inconvenience of little open door for site alteration. The general shaft lengths need steel beam manufacture inside tight cutoff points, despite the fact that packs are utilized to make up for creation resiliency and erection resistances. At long last, end plate connections are not reasonable for tall steel beam structures.

6.SPECIAL CONNECTIONS-SIMPLE, RIGID AND SEMI-RIGID CONNECTIONS:

This kind of connection is utilized for the situation where the courses of action of the basic component are so that standard connections can't be utilized. For instance, intersection angels may be diverse by a specific degree and when pillar focuses counterbalance from section focus. Instances of special connections incorporate twisted plate surrounded, single web plate, uneven confined, adjusted web plate and z type connection.

- Simple connections are intended to transmit just shear from the pillar to the segment without creating noteworthy minutes.

- Rigid connections are connections that don't misshape altogether under applied minutes. This implies they have rotational restrictions of 90% or more. At the end of the day, it is given full continuity at the connection.

- Semi-rigid connections are intended to have some level of rotational restriction and along these lines will pull in certain minutes. This implies the minute transmitted over the joint is neither zero, nor is it the full progression minute as rigid connections.

A steel beam structure is made up of linkages between different persons, such as segments, bars, and beams. The structural parts used to interconnect numerous persons from steel structures are known as connections.