Beam vs Column: Key Differences and Best Steel for RCC

Every site engineer or contractor knows that a project’s stability depends on two key elements, beams and columns. Yet, what often decides how safely and efficiently a building performs is not just its presence, but how they are designed, reinforced, and sourced.

With tight deadlines and fixed budgets, even the smallest miscalculation in beam or column detailing can lead to costly rework, uneven load transfer, or long-term structural issues. That is why understanding how these two components differ in function, behavior, and reinforcement is essential before steel procurement or RCC design begins.

In this blog, we’ll explore the key distinctions between beams and columns. By the end, you'll have the insights needed to make smarter material and design choices, ensuring a balance between safety, cost, and performance from the ground up.

Key Takeaways:

-

Structural Clarity: Understanding beam-column interaction ensures safe and durable buildings.

-

Right Material: Use verified TMT bars and construction rods in correct diameters and grades.

-

Procurement Edge: SteelonCall delivers verified steel from trusted brands directly to your site.

-

Project Efficiency: Live prices, bulk orders, and timely delivery streamline construction operations.

What Is a Beam in Construction?

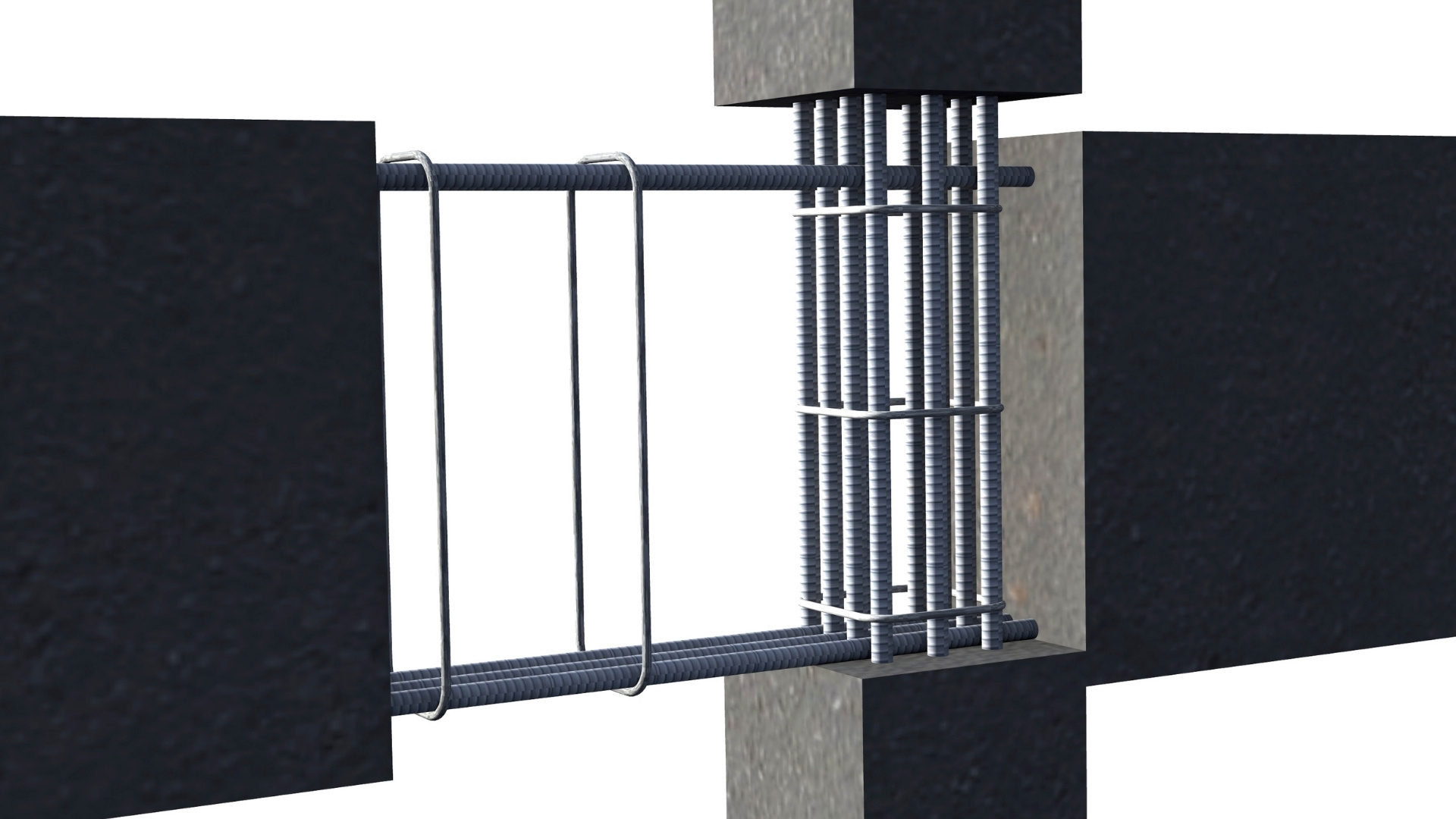

A beam is a horizontal structural element that carries loads from slabs, walls, or other structural components and transfers them to columns or walls. Beams resist bending and shear forces, ensuring that floors and ceilings remain stable.

Materials and Construction:

-

Beams are made from RCC, combining concrete with TMT bars as reinforcement.

-

TMT bars are placed longitudinally along the beam to resist tensile forces, while stirrups (transverse bars) hold the longitudinal bars in position and resist shear.

-

Proper placement and spacing of TMT bars ensure uniform load distribution and prevent cracking.

Types of Beams:

-

Simply Supported Beam: Supported at both ends; common in residential and commercial buildings.

-

Cantilever Beam: Supported at one end only; often used in balconies or projections.

-

Continuous Beam: Extends over multiple supports for longer spans.

-

Slab Beam: Integrates with floor slabs to distribute loads efficiently.

Also Read: What Are Steel Beams? Briefly Explained

What Is a Column in Construction?

A column is a vertical structural element that transfers loads from beams and slabs down to the foundation. Columns resist compressive forces and provide overall stability to a structure.

Materials and Construction:

-

Columns are made from RCC, reinforced with vertical TMT bars tied together with horizontal stirrups.

-

Longitudinal TMT bars carry compressive loads, while stirrups prevent buckling and provide confinement to the concrete.

Types of Columns:

-

Tie Column: Reinforced with vertical bars and lateral ties; standard for vertical load transfer in buildings.

-

Composite Column: Combines different reinforcement layouts for added strength in high-load areas.

-

Short Column: Height is less than three times the least lateral dimension; fails by crushing.

-

Long Column: Height exceeds three times the least lateral dimension; failure occurs due to buckling.

Buyer-Focused Note: Beams and columns rely on high-quality TMT bars in precise diameters and grades. Verified steel ensures compliance with design specifications, reduces on-site errors, and improves long-term safety.

Beam vs Column: Key Structural Differences

Although both beams and columns are vital parts of an RCC structure, their functions and the stresses they handle are very different. Understanding these differences helps ensure each member is designed and reinforced correctly on site.

| Aspect | Beam | Column |

|---|---|---|

|

Orientation |

Placed horizontally to connect columns and support slabs or walls. |

Positioned vertically to carry the load from beams and slabs. |

|

Type of Load |

Designed to resist bending and shear forces. |

Designed to resist compressive and buckling forces. |

|

Main Function |

Transfers the load of slabs or walls to the columns. |

Transfers the load from beams down to the foundation. |

|

Steel Reinforcement |

Placed mostly at the bottom region to resist tension due to bending. |

Arranged evenly to handle compression and prevent buckling. |

|

Failure Impact |

Affects a section of the floor or roof. |

Affects the overall stability of the structure. |

The distinction is not only structural but practical. Beams are visible during slab work and are often the first indicators of alignment or deflection issues.

Columns define the grid of the building and determine how evenly the load is distributed to the ground. When both are properly reinforced with the right TMT grade, the structure performs well under everyday and extreme conditions.

Role of TMT Bars in Beams and Columns

TMT bars are the backbone of reinforced concrete beams and columns, providing strength, flexibility, and safety. They help structures withstand bending, shear, and compressive forces, ensuring long-lasting stability.

Why TMT Bars Matter on Site

-

Beams: TMT bars provide tensile strength where concrete naturally cracks under bending.

-

Columns: They enhance compressive strength and ductility, helping buildings endure heavy loads and seismic stress.

-

Practical Impact: Using the correct TMT grade reduces the risk of cracks, rework, and structural issues, keeping projects safe and on schedule.

Recommended Grades and Typical Pricing

Here's a practical snapshot for buyers comparing popular TMT brands and grades. Prices are indicative and depend on order quantity:

| Brand | Grade | Price |

|---|---|---|

|

Fe 550D |

Starts from ₹42,700 |

|

|

Fe 500D |

Starts from ₹51,000 |

|

|

Fe 500D |

Starts from ₹53,000 |

|

|

Fe 550D |

Starts from ₹48,700 |

*Prices may vary by region, bulk order, and market fluctuations, and are excluding taxes.

Buyer Tip: Selecting the right grade not only affects strength and safety but can also optimize your project costs. Higher-grade bars may reduce the total reinforcement required, saving on handling and labor.

Also Read: Why TMT Bars Are the Pillars of Your Foundation?

Why Quality and Sourcing of TMT Steel Matter?

Using the right TMT bars is critical for safety, durability, and cost efficiency in beams and columns. Low-quality or uncertified steel can compromise structural performance, increase rework, and delay projects.

-

Structural Strength: High-quality TMT bars provide consistent yield strength and ductility, essential for beams and columns to handle bending and compressive loads safely.

-

Durability: Verified steel resists corrosion and cracking, ensuring that structures last longer and require less maintenance over time.

-

Compliance: Properly sourced TMT bars come with mill test certificates, meeting design and regulatory requirements.

-

Project Efficiency: Reliable sourcing ensures the timely delivery of the correct grade and size, reducing delays, material wastage, and on-site errors.

Why Choose SteelonCall for Beams and Columns?

Every durable building relies on properly designed and reinforced beams and columns. While TMT bars and RCC reinforcement are critical, how you source steel can determine the success of a project. SteelonCall makes it simple, reliable, and efficient for contractors, builders, and fabricators.

Key Services and Advantages:

-

Verified TMT Bars and Construction Rods: Access a wide range of Fe 500D, Fe 550D, and other grades in precise diameters, ideal for residential, commercial, and industrial RCC projects.

-

Multiple Brands in One Marketplace: Choose from trusted names like Tata, JSW, Vizag, and SAIL, and a lot more.

-

Live Prices: Check real-time pricing for all TMT bars and construction rods, allowing buyers to make cost-effective decisions instantly.

-

Bulk Procurement Made Easy: SteelonCall enables large-volume orders with accurate sizing and grades, streamlining procurement for multi-storey buildings or industrial structures.

-

On-Time Delivery Across India: Coordinated logistics ensure steel arrives as per your project schedule, reducing downtime and keeping construction on track.

-

Digital Convenience: Place orders, track shipments, and manage multiple projects through SteelonCall's online platform and mobile app, saving time for engineers and site managers.

By sourcing from verified brands with live pricing and assured quality checks, SteelonCall helps contractors maintain structural accuracy, minimize site errors, and build with confidence.

Conclusion

Beams and columns are critical to the stability and durability of any RCC structure. Their effectiveness depends on correct design, precise placement, and high-quality reinforcement.

Sourcing verified TMT bars and construction rods in the right diameters and grades is essential for maintaining structural integrity, minimizing wastage, and keeping projects on schedule.

With SteelonCall, contractors and builders gain access to trusted brands, making steel procurement simple, reliable, and efficient.

FAQs

1. What are beams and columns, and why are they important in construction? >

A beam and column form the basic framework of RCC structures. Beams distribute loads horizontally, while columns transfer them vertically to the foundation. Understanding their roles ensures safe and durable buildings.

2. How does a column beam structure differ from other structural layouts?

A column beam structure creates a skeleton framework where columns support vertical loads and beams connect them horizontally. This layout allows for multi-storey construction, even load distribution, and improved seismic resistance.

3. Column vs beam: Which one is more critical for structural safety?

Both are essential, but columns carry the building’s total load down to the foundation. While beam failure affects specific sections, column failure can compromise the entire structure, making correct design and reinforcement vital.

4. How do beam vs column orientations affect load handling in RCC buildings?

Beams are horizontal elements designed to resist bending and shear, while columns are vertical and resist compressive forces. Proper orientation and reinforcement ensure efficient load transfer and prevent structural defects.

5. What factors should be considered in a beam and column structure for long-lasting durability?

Factors include TMT grade selection, correct placement of reinforcement, adequate concrete cover, and verified steel sourcing. Using high-quality materials and following engineering design ensures a strong and durable beam and column structure.